Let’s just take a moment to appreciate the colorful resin 3D prints above. Using resin, you can bring all types of 3D printing ideas to life. Your favorite Marvel characters such as Iron Man, Captain America, the Hulk, and either other superhero, can easily be printed out and displayed as a collectible at your home, the workspace, or anywhere you like.

But, with a wide variety of resins available on the market, which one should you get?

Today, we’ll provide you with a Starter Guide that lets you know which Phrozen resins are the best for beginners and enthusiasts.

We recommend resins from the Aqua series (Blue, Green, Gray 4K, and Ivory 4K), ABS-like series (Matte Gray, Creamy White), Beige Flex, and Clear Resin for those just starting out with resin 3D printing.

Let’s get into the features and characteristics of each type of resin and what they can be used for:

Aqua Series

Aqua-Gray 4K & Aqua-Ivory 4K Resin — Best for Extremely-Detailed 3D Prints

Phrozen Aqua-Gray 4K and Aqua-Ivory 4K resins create prints with extremely high resolution and are best for printing out highly intricate 3D printing models with a smooth surface and no horizontal lines. Using Aqua-Gray 4K resin, the Black Panther bust statue in the photo above was printed with all the tiny details, allowing the 3D print to be as textured as possible.

3D Model Credit: Loot Studios

3D Model Credit: Loot Studios

With its light color, Aqua-Ivory 4K is perfect for painting over with a variety of colors to make your 3D prints as lifelike as possible. Aqua-Ivory 4K is also extremely suitable for printing out large-scale & detailed 3D models with the help of bigger 3D printers such as the Sonic Mighty 4K or Sonic Mega 8K.

As a maker, if you are looking to print out 3D printable models with extreme details and no horizontal lines, Aqua-Gray 4K and Aqua-Ivory 4K resin would be your best choice.

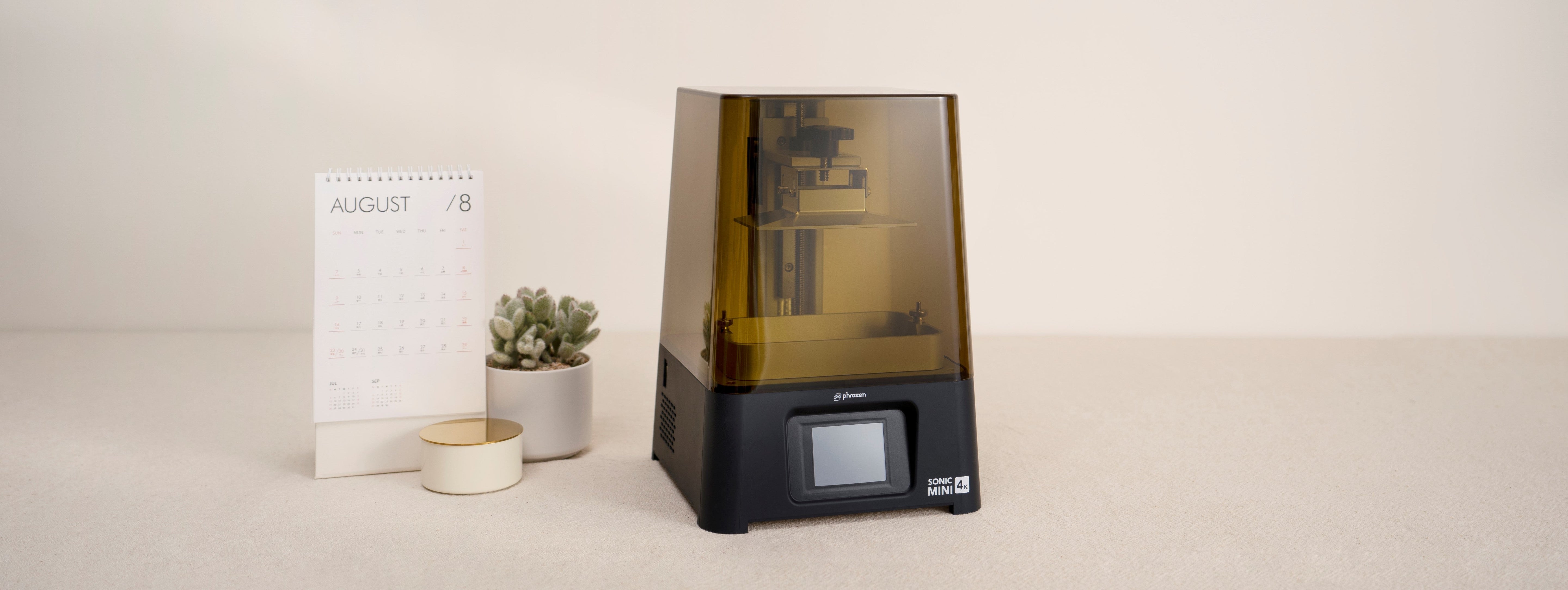

This resin works best with Phrozen LCD 3D Printers: Sonic Mini 4K, Sonic Mighty 4K, and Sonic Mega 8K.

Characteristics:

Phrozen 4K resins produce 3D models with extremely high precision. Low viscosity also makes it easy to rinse and clean 3D prints after printing is complete.

Features (Aqua-Gray 4K):

Viscosity: 150cps

Density: 1.1

Tg (Glass Transition Temperature): 68.4℃

Surface Hardness (Shore D): Shore 77 D

Elongation (at break): 7%

Tensile Strength: 2 Mpa

I-Zod Impact: 6.78 KJ/m2

Features (Aqua-Ivory 4K):

Viscosity: 221cps

Density: 1.1

Surface Hardness (Shore D): Shore 75 D

Elongation (at break): 6%

Tensile Strength: 1.9 Mpa

Aqua-Blue & Aqua-Green Resin - Best for Colorful 3D Prints

With its bright colors, Phrozen Aqua-Blue resin and Aqua-Green resin allow makers to print out vibrant and flashy 3D models that grab people’s attention quickly. Look at the T-Rex printed with Aqua-Green resin in the photo above. Doesn’t it seem menacing and lifelike?

Aqua-Blue and Aqua-Green resins can bring a pop of color to all your creations instead of the usual neutral resin colors. As a bonus, you don’t need to paint your models after printing.

Characteristics:

Both Aqua-Blue and Aqua-Green resin create non-brittle 3D printable models with ease. Aqua-Blue and Aqua-Green resins have higher tensile strength, or resistance to breaking under pressure, than Aqua-Gray 4K resin.

These two resins have the lowest shrinkage rates in all Phrozen resins, making them ideal for high precision printing. Both Aqua-Green and Aqua-Blue resins have a lower viscosity than Aqua-Gray 4K, though Aqua-Green has a slightly lower viscosity than Aqua-Blue resin.

Features (Aqua-Blue):

Viscosity: 130cps

Density:1.12

Tg (Glass Transition Temperature): 82℃

Surface Hardness (Shore D): Shore 86 D

Elongation (at break): 21%

Tensile Strength: 24 Mpa

I-Zod Impact: 1.81KJ/m2

Features (Aqua-Green):

Viscosity: 125cps

Density: 1.12

Tg (Glass Transition Temperature): 80℃

Surface Hardness (Shore D): Shore 86 D

Elongation (at break): 21%

Tensile Strength: 24 Mpa

I-Zod Impact: 1.81KJ/m2

Aqua-Gray 8K Resin - Best for Extremely Intricate 8K Quality 3D Prints

With its matte gray finish, Phrozen’s all-new Aqua-Gray 8K Resin is capable of showcasing striking details in 8K resolution and works best with the Sonic Mini 8K 3D Printer. Aqua-Gray 8K creates extremely intricate and lifelike 3D models that appear professionally made.

We recommend using Aqua-Gray 8K resin to create all sorts of high-quality miniatures, rings, delicate jewelry, and more.

Characteristics:

Phrozen Aqua-Gray 8K creates low shrinkage, high-resolution models with a certain toughness. It’s also extremely easy to rinse and clean once your 8K quality 3D prints are ready.

Features:

Viscosity: 420 cps

Density: 1.1 g

Surface Hardness (Shore D): Shore 85 D

Elongation: 18 %

Tensile Strength: 43.17 Mpa

I-Zod Impact: 11.73 KJ/m2

ABS-like Series

Matte Gray & Creamy White - Best for Painting

With its light color, both Phrozen Matte Gray resin and Creamy White resin are excellent for makers looking to print models with neutral shades. Resins in the ABS-like series are one of the most widely used resins for LCD 3D printing and currently have the highest print success rate in comparison to all other Phrozen resins.

The model in the picture above was printed with ABS-like Creamy White resin. Look at the pure white color and textured surface. These resin 3D models can easily be painted over with any color you like as it can be used as a base color.

Characteristics:

Out of all Phrozen resins, both ABS-like Matte Gray resin and Creamy White resin have the lowest viscosity levels and are capable of producing high-resolution 3D models that are sturdy.

Features (ABS-like Matte Gray):

Viscosity: 67 cps

Density: 1.1

Tg (Glass Transition Temperature): 70℃

Surface Hardness (Shore D): Shore 76 D

Elongation (at break): 3%

Tensile Strength: 10 Mpa

I-Zod Impact: 1.44 KJ/m2

Features (ABS-like Creamy White):

Viscosity: 77 cps

Density: 1.1

Tg (Glass Transition Temperature): 70℃

Surface Hardness (Shore D): Shore 79 D

Elongation (at break): 2%

Tensile Strength: 12 Mpa

I-Zod Impact: 2.32 KJ/m2

Beige Flex - Best for Prototyping

With its light color, Beige Flex resin is also best suited for printing out neutral color 3D models that can easily be painted over due to its hydrophilic surface. A hydrophilic surface becomes wet easily, which means it can easily be painted on after the resin has dried. This is important as plastic resin can sometimes be hard to paint over.

You can use Beige Flex to print out prototype models or 3D models with movable parts to express your creativity.

Characteristics:

Beige Flex has an extremely high tensile strength, which means that 3D models printed using this resin will be tough and won’t break easily.

Features:

Viscosity: 540cps

Density: 1.1

Tg (Glass Transition Temperature): 74℃

Surface Hardness (Shore D): Shore 68 D

Elongation (at break): 26%

Tensile Strength: 12 Mpa

I-Zod Impact: 5.3 KJ/m2

Mud-like Resin - Best for Vibrant 3D Prints with Details

With its eye-catching color and nanoceramic particles, Phrozen Mud-like Resin is great for creating high-quality & sturdy resin 3D prints. Mud-like Resin is ideal for creating 3D models with realistic facial expressions, as the resin precisely showcases skin texture, wrinkles, and more, with a matte finish.

We recommend using this resin to create vibrant and colorful 3D printed head busts and sculpts.

Characteristics:

Phrozen Mud-like Resin has very low shrinkage rate, so you don’t need to worry about your 3D models changing in shape after printing.

Features:

Viscosity: 360 cps

Tg (Glass Transition Temperature): 65 ℃

Surface Hardness (Shore D): Shore 89 D

Elongation: 9%

Tensile Strength: 32 Mpa

I-Zod Impact: 6.5 KJ/m2

Aqua Clear Resin - Best for Transparent Prints

Phrozen Aqua Clear resin creates highly-transparent 3D models that don’t yellow after the post-curing process. Using this, you can print a wide variety of see-through 3D objects such as 3D collectible models — like the deer family in the above image — clear prototype parts, optical parts, and other translucent models depending on your needs.

You will need to post-process your prints to remove any layer lines present on your 3D prints in order to have a crystal clear finish.

Characteristics:

Aqua Clear Resin produces 3D models that have extremely high heat resistance and a high tensile strength so that 3D prints don’t break easily under pressure.

Features:

Viscosity - 142cps

Density - 1.1

Tg (Glass Transition Temperature) - 73℃

Surface Hardness (Shore D) - Shore 70 D

Elongation (at break) - 17%

Tensile Strength - 12 Mpa

I-Zod Impact - 2.68 KJ/m2

There you have it, a detailed breakdown of which Phrozen resins are the best for beginners and enthusiasts.

Please refer to our resin profile chart for a general idea on how to set up resin profiles for other Phrozen resins. Feel free to make adjustments to see what works best for you.

Check out our previous blog post in which we explain which Phrozen LCD 3D printers are best for beginners.

11 comments

YUGUO

Hi,I want to ask Aqua-Gray 8K Resin’s Tg (Glass Transition Temperature),THANKS

———

Phrozen Technology replied:

Hello Yuguo, Thank you for commenting.

The Tg of the material was not in both the standard testing programme of our resin product, and the expected using scenario of the material. Thus we are not able to provide the data of what you are looking for.

Thank you.

Best, Phrozen Team

>

Hi,I want to ask Aqua-Gray 8K Resin’s Tg (Glass Transition Temperature),THANKS

———

Phrozen Technology replied:

Hello Yuguo, Thank you for commenting.

The Tg of the material was not in both the standard testing programme of our resin product, and the expected using scenario of the material. Thus we are not able to provide the data of what you are looking for.

Thank you.

Best, Phrozen Team

>

Gasper

I plan to purchase complete workflow for Mega 8k S

Resin 1:

I want to print large parts for motorcycles – meaning they need to have paint ready smooth surface and must be temperature resistant up to around 90°C, UV resistant and material must be appropriate for outdoor use.

Parts printed will be monocoques – hollow, and will be filled with various foams – will inner surface be fully cured during printing process ?

Which resin to use?

Can resin be colored prior printing if we would like to have it black, but other colors would perform better?

Resin 2:

Manufacturing molds for composite parts (Carbon)

Should have very smooth surface and resistant to 130°C for two hours at 5 bar of pressure. If not avalable, what is closest to that, since we can adopt curing cycle a bit.

What resin to use? how to temper (increase temperature resistance) it?

I need to know what spare parts are needed for continious prining of parts.

All info about workflow are highly appreciated.

Thanks, Gasper

———

Phrozen Technology replied:

Hi Gasper,

1. Resin printed objects are having smooth surface overall, especially when anti-aliasing is enabled. To achieve a smooth surface in resin printing depends on model design, orientation, and print parameters. Proper model preparation, orientation, and resin settings are crucial for optimal results.

2. For outdoor use, consider applying a UV-resistant prime spray after printing. Heat-resistant resins like Phrozen TR300 are suitable. However, the actual outdoor performance can be affected by complex environmental factors.

3. Hollow prints can be achieved through model design or settings in slicer software. Cure the interior part of a printed object with UV light of the same wavelength as post-curing is a necessary. Objects with uncured interiors may deform or break.

4. Based on your description, our initial judgment will recommend the Phrozen TR300 resin for its balance of properties.

5. Resin colouring is typically done after printing using paints or dyes. Each resin has its inherent colour; for example, TR300 is black, therefore the objects printed out using TR300 will be black.

6. TR300 has a heat deflection temperature of 156°C, suitable for industrial prototyping. For higher temperature resistance, consider Phrozen Dental Ortho Model Resin (190°C) or Ceramic White Resin which also has outstanding wear resistance, durability and temperature resistance.

7. Heat resistance is intrinsic to the resin’s material properties and can’t be externally altered.

8. For a printing farm, we suggest to keep extra releasing film, resin, and LCD screens. Use protective films on LCDs to prevent damage from resin leakage. Maintain stable humidity, temperature, and good ventilation in your working environment.

Feel free to contact our customer support for further assistance or detailed workflow information.

Best regards, Phrozen Team

>

I plan to purchase complete workflow for Mega 8k S

Resin 1:

I want to print large parts for motorcycles – meaning they need to have paint ready smooth surface and must be temperature resistant up to around 90°C, UV resistant and material must be appropriate for outdoor use.

Parts printed will be monocoques – hollow, and will be filled with various foams – will inner surface be fully cured during printing process ?

Which resin to use?

Can resin be colored prior printing if we would like to have it black, but other colors would perform better?

Resin 2:

Manufacturing molds for composite parts (Carbon)

Should have very smooth surface and resistant to 130°C for two hours at 5 bar of pressure. If not avalable, what is closest to that, since we can adopt curing cycle a bit.

What resin to use? how to temper (increase temperature resistance) it?

I need to know what spare parts are needed for continious prining of parts.

All info about workflow are highly appreciated.

Thanks, Gasper

———

Phrozen Technology replied:

Hi Gasper,

1. Resin printed objects are having smooth surface overall, especially when anti-aliasing is enabled. To achieve a smooth surface in resin printing depends on model design, orientation, and print parameters. Proper model preparation, orientation, and resin settings are crucial for optimal results.

2. For outdoor use, consider applying a UV-resistant prime spray after printing. Heat-resistant resins like Phrozen TR300 are suitable. However, the actual outdoor performance can be affected by complex environmental factors.

3. Hollow prints can be achieved through model design or settings in slicer software. Cure the interior part of a printed object with UV light of the same wavelength as post-curing is a necessary. Objects with uncured interiors may deform or break.

4. Based on your description, our initial judgment will recommend the Phrozen TR300 resin for its balance of properties.

5. Resin colouring is typically done after printing using paints or dyes. Each resin has its inherent colour; for example, TR300 is black, therefore the objects printed out using TR300 will be black.

6. TR300 has a heat deflection temperature of 156°C, suitable for industrial prototyping. For higher temperature resistance, consider Phrozen Dental Ortho Model Resin (190°C) or Ceramic White Resin which also has outstanding wear resistance, durability and temperature resistance.

7. Heat resistance is intrinsic to the resin’s material properties and can’t be externally altered.

8. For a printing farm, we suggest to keep extra releasing film, resin, and LCD screens. Use protective films on LCDs to prevent damage from resin leakage. Maintain stable humidity, temperature, and good ventilation in your working environment.

Feel free to contact our customer support for further assistance or detailed workflow information.

Best regards, Phrozen Team

>

Massimo

I have dental lab. I produce ,just dental cast for orthodontic aligner. I have two machines: sonic 4k xl plus and sonic mega 8k. Which resin is economic for these printers.

Regards

———

Phrozen Technology replied:

Hello Massimo,

Thank you for commenting. For dental products, please contact our dental product agent to get further information and assistance, by submit a request via this link.

https://dental.phrozen3d.com/pages/contact

Hope this helps and have a great day.

Best, Phrozen Team

>

I have dental lab. I produce ,just dental cast for orthodontic aligner. I have two machines: sonic 4k xl plus and sonic mega 8k. Which resin is economic for these printers.

Regards

———

Phrozen Technology replied:

Hello Massimo,

Thank you for commenting. For dental products, please contact our dental product agent to get further information and assistance, by submit a request via this link.

https://dental.phrozen3d.com/pages/contact

Hope this helps and have a great day.

Best, Phrozen Team

>

Dave Dening

I just finished my first print with TR300 using an Egloo Mars Pro. I’m impressed by the resin’s toughness in snapping off the supports. But, in cleaning up the printer there was a sticky layer even after a wash in 99% isopropyl alcohol. And, the prints were sticky even after a quick wash.

What can I use to clean off the resin left on the printer?

———

Phrozen Technology replied:

Hi Dave,

For cleaning the leftover resin, we recommend our customers to follow these steps. Firstly, spray 95% sanitizing alcohol, IPA onto the FEP or the PFA (nFEP) film. Then, use a soft kitchen paper towel or fiber cloth to clean the leftover resin. Repeat this step until the resin vat is clean and make sure to clean the edges as well. This will ensure that the resin vat is thoroughly cleaned and ready for the next use.

If you see cured resin particles scattered around the vat, please check your printer’s manual, and see if you can find any function like the vat cleaning that we provided with our printers. You can check out this article about vat cleaning function in our helpcentre: https://reurl.cc/pLgZW8

Hope you find this helpful!

Regards, Phrozen Team.

>

I just finished my first print with TR300 using an Egloo Mars Pro. I’m impressed by the resin’s toughness in snapping off the supports. But, in cleaning up the printer there was a sticky layer even after a wash in 99% isopropyl alcohol. And, the prints were sticky even after a quick wash.

What can I use to clean off the resin left on the printer?

———

Phrozen Technology replied:

Hi Dave,

For cleaning the leftover resin, we recommend our customers to follow these steps. Firstly, spray 95% sanitizing alcohol, IPA onto the FEP or the PFA (nFEP) film. Then, use a soft kitchen paper towel or fiber cloth to clean the leftover resin. Repeat this step until the resin vat is clean and make sure to clean the edges as well. This will ensure that the resin vat is thoroughly cleaned and ready for the next use.

If you see cured resin particles scattered around the vat, please check your printer’s manual, and see if you can find any function like the vat cleaning that we provided with our printers. You can check out this article about vat cleaning function in our helpcentre: https://reurl.cc/pLgZW8

Hope you find this helpful!

Regards, Phrozen Team.

>

Michael Lindsay

Hi,

I’m looking for a very opaque bright white resin. I’ve tried a few different brands but they do not print with enough detail (similar to the grey abs like). Some voids are filled in making the prints unusable for what I need them for.

Why are the grey resins the most suited to detailed prints? Is it due to the pigments blocking the excess light more efficiently or am I simply using the wrong settings.

Thanks

———

Phrozen Technology replied:

Hi Michael, if you are looking for gray resins that offer the highest result of details, then we recommend the Aqua-Gray 8K. You may also look into our Aqua-Gray 4K for another gray option or the BASF Protowhite for a bright, clean white resin.

Cheers, Phrozen Team

>

Hi,

I’m looking for a very opaque bright white resin. I’ve tried a few different brands but they do not print with enough detail (similar to the grey abs like). Some voids are filled in making the prints unusable for what I need them for.

Why are the grey resins the most suited to detailed prints? Is it due to the pigments blocking the excess light more efficiently or am I simply using the wrong settings.

Thanks

———

Phrozen Technology replied:

Hi Michael, if you are looking for gray resins that offer the highest result of details, then we recommend the Aqua-Gray 8K. You may also look into our Aqua-Gray 4K for another gray option or the BASF Protowhite for a bright, clean white resin.

Cheers, Phrozen Team

>

Shaneel

Hi,

What is the post curing time required for the resins TR300 & TR250 ?

———

Phrozen Technology replied:

Hi Shaneel, thanks for your comment! Please post-cure both TR300 & TR250 for at least 30 minutes to ensure the models are thoroughly cured.

Cheers, Phrozen Team

>

Hi,

What is the post curing time required for the resins TR300 & TR250 ?

———

Phrozen Technology replied:

Hi Shaneel, thanks for your comment! Please post-cure both TR300 & TR250 for at least 30 minutes to ensure the models are thoroughly cured.

Cheers, Phrozen Team

>

IRMAK

Hi, which resin is the most suitable for making the most durable/flexible 3D printed figurines or busts that will have a long shelf life?

———

Phrozen Technology replied:

Hey IRMAK,

Thank you for your comment! For best results, we would recommend Aqua-Gray 4K resin.

Cheers, Phrozen Team

Hi, which resin is the most suitable for making the most durable/flexible 3D printed figurines or busts that will have a long shelf life?

———

Phrozen Technology replied:

Hey IRMAK,

Thank you for your comment! For best results, we would recommend Aqua-Gray 4K resin.

Cheers, Phrozen Team

RAMI MOSLEM

What is suitable settings (Resin Profile) for using Washable Dental Models resin for producing high quality dental models and ditched dies using Sonic Mini 4K?

———

Phrozen Technology replied:

Hi there,

Thank you for your comment. Please refer to our resin profile page to find the answer to your question: https://phrozen3d.com/pages/resin-profile

What is suitable settings (Resin Profile) for using Washable Dental Models resin for producing high quality dental models and ditched dies using Sonic Mini 4K?

———

Phrozen Technology replied:

Hi there,

Thank you for your comment. Please refer to our resin profile page to find the answer to your question: https://phrozen3d.com/pages/resin-profile

Isaac

Hi, which resin would be best suited for printing very large parts (full build platforms on the Mega) that will be assembled / glued together to form a larger model? Specifically which resin would have the lowest deformation after curing so that alignment between pieces is easier?

Thanks,

———

Phrozen Technology replied:

Hi there,

Thank you for your comment! If you’re planning on printing out Industrial parts, we would recommend TR300 Resin. If you’re looking to print out action figurines or other 3D prints, we would recommend Aqua-Gray 4K or Aqua-Ivory 4K Resin.

Hi, which resin would be best suited for printing very large parts (full build platforms on the Mega) that will be assembled / glued together to form a larger model? Specifically which resin would have the lowest deformation after curing so that alignment between pieces is easier?

Thanks,

———

Phrozen Technology replied:

Hi there,

Thank you for your comment! If you’re planning on printing out Industrial parts, we would recommend TR300 Resin. If you’re looking to print out action figurines or other 3D prints, we would recommend Aqua-Gray 4K or Aqua-Ivory 4K Resin.

Phrozen Team

Hi there, thank you for your comment!

“ABS” stands for Acrylonitrile butadiene styrene which is a chemical compound used to create resins. Please refer to this link to learn more about our functional resins: https://phrozen3d.com/collections/functional-resins

Hi there, thank you for your comment!

“ABS” stands for Acrylonitrile butadiene styrene which is a chemical compound used to create resins. Please refer to this link to learn more about our functional resins: https://phrozen3d.com/collections/functional-resins

Bo R McCullough

This is very informative. What does ‘ABS’ stand for and which resins work best for applications requiring some flexibility?

This is very informative. What does ‘ABS’ stand for and which resins work best for applications requiring some flexibility?