Cost-Effective, High Toughness Resin for Manufacturing Aids

Simulating the strength and stiffness of polypropylene (PP) thermoplastic, Tough 100E Resin is an excellent cost-effective alternative for creating jigs, fixtures, and rapid tooling compared to traditional molding process or CNC manufacturing.

See how one of our users — a car manufacturer in Taiwan incorporated Tough 100E 3D printed fixtures to help their factory produce car armrests.

Great Toughness, Exceptional Elasticity

Bendable and twistable with remarkable flex, it’s an excellent choice for printing fixtures, clamps, and snap-fit parts.

Durable and Impact-Resistance

Effortlessly maintaining its integrity even in high-impact situations, it creates durable, long-lasting jigs and tools to ease your production process.

Smoother, Safer Manufacturing

Create jigs and fixtures with Tough 100E Resin to increase efficiency, enhance safety, and lower production costs throughout your manufacturing process.

Best Paired With Sonic Mega 8K V2

Print up to 40 cm tall of jigs, fixtures, and clamps with great accuracy, efficiently reducing the production time from over 2 weeks to less than 3 days at a time.

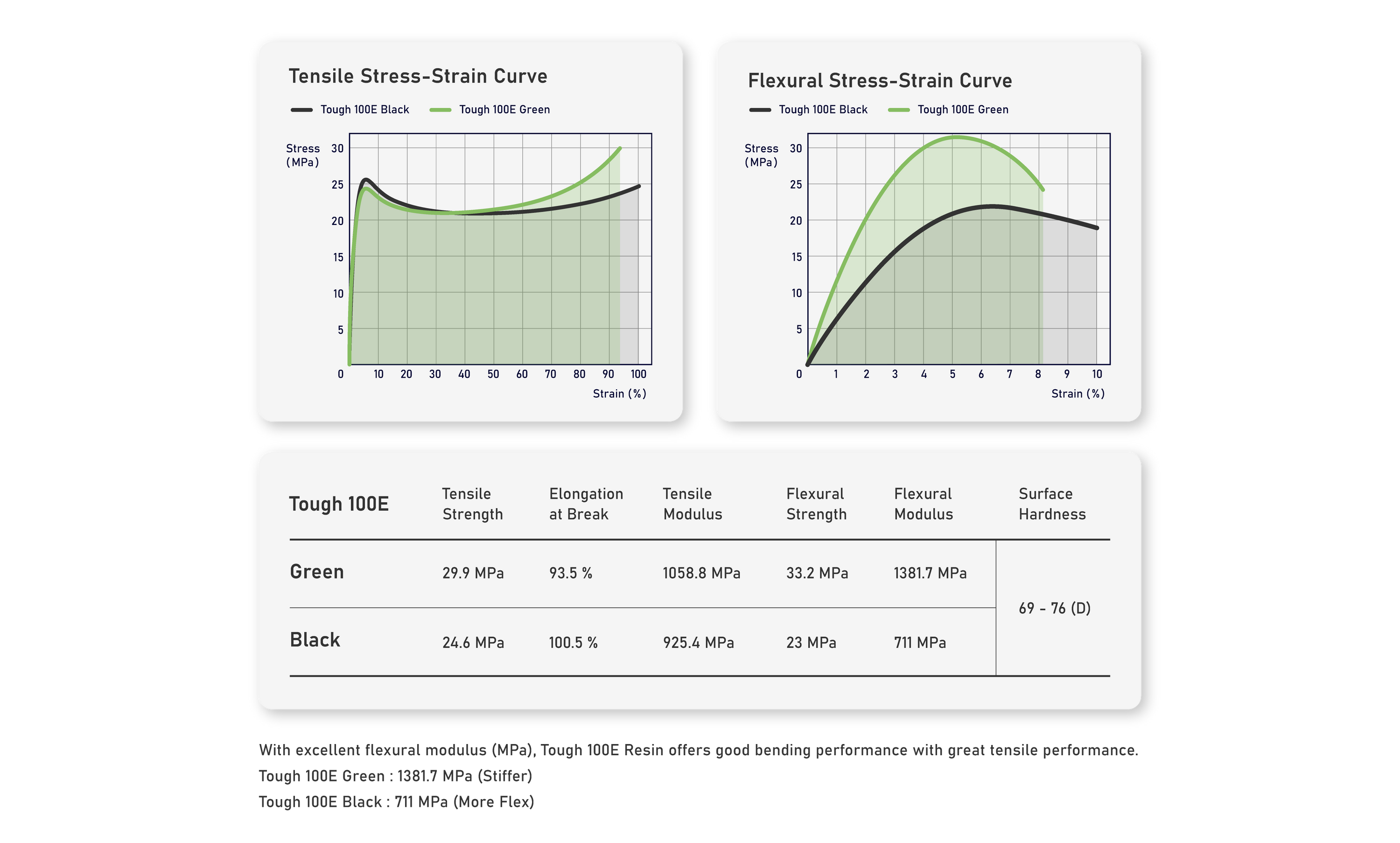

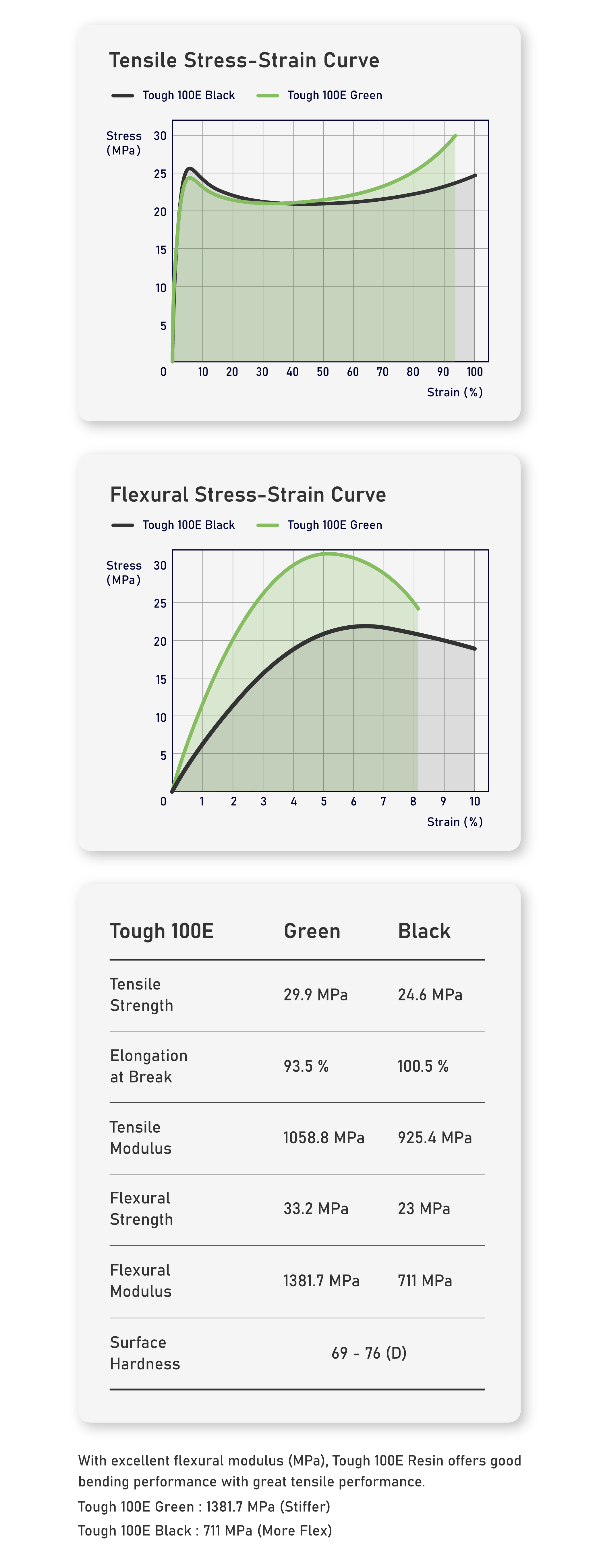

Resin Properties

What Else Can Tough 100E Do?

Not limited to manufacturing aids such as jigs and fixtures, Tough 100E Resin is also highly suitable for various product prototypes and development needs.

Snap-Fit Lid

With high elongation and moderate stiffness, it easily snugs and locks into place.

Squeeze Bottle

Simulate the springiness of a squeeze bottle from its early prototype thanks to its high elongation and flex.

Glasses Frame

Test your flex glasses frame before production with a prototype perfectly replicating the shapes, integrity, and flex of its end products.