Have you thought how cool it would be if your miniatures were not as fragile, so you could play and handle them with ease? Well, maybe you'll need the unbreakable resin!

In this article, one of our most in-depth 3D printing torture testers is back with his review of what he called the unbreakable resin.

Want to know more about it? Just keep reading!

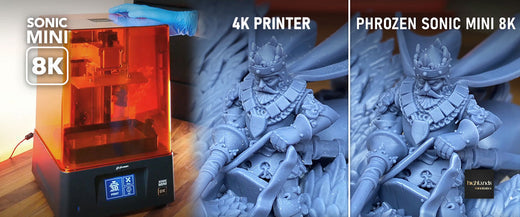

Formulated as a functional engineering resin, the Phrozen ONYX Impact Plus was made to be stronger and tougher than others, with up to 5x impact resistance capabilities. With opaque, black color and extremely thick viscosity, it's definitely not your everyday resin. But once you try them, the possibility is endless.

Dennys' Printing Experience With ONYX Impact Plus

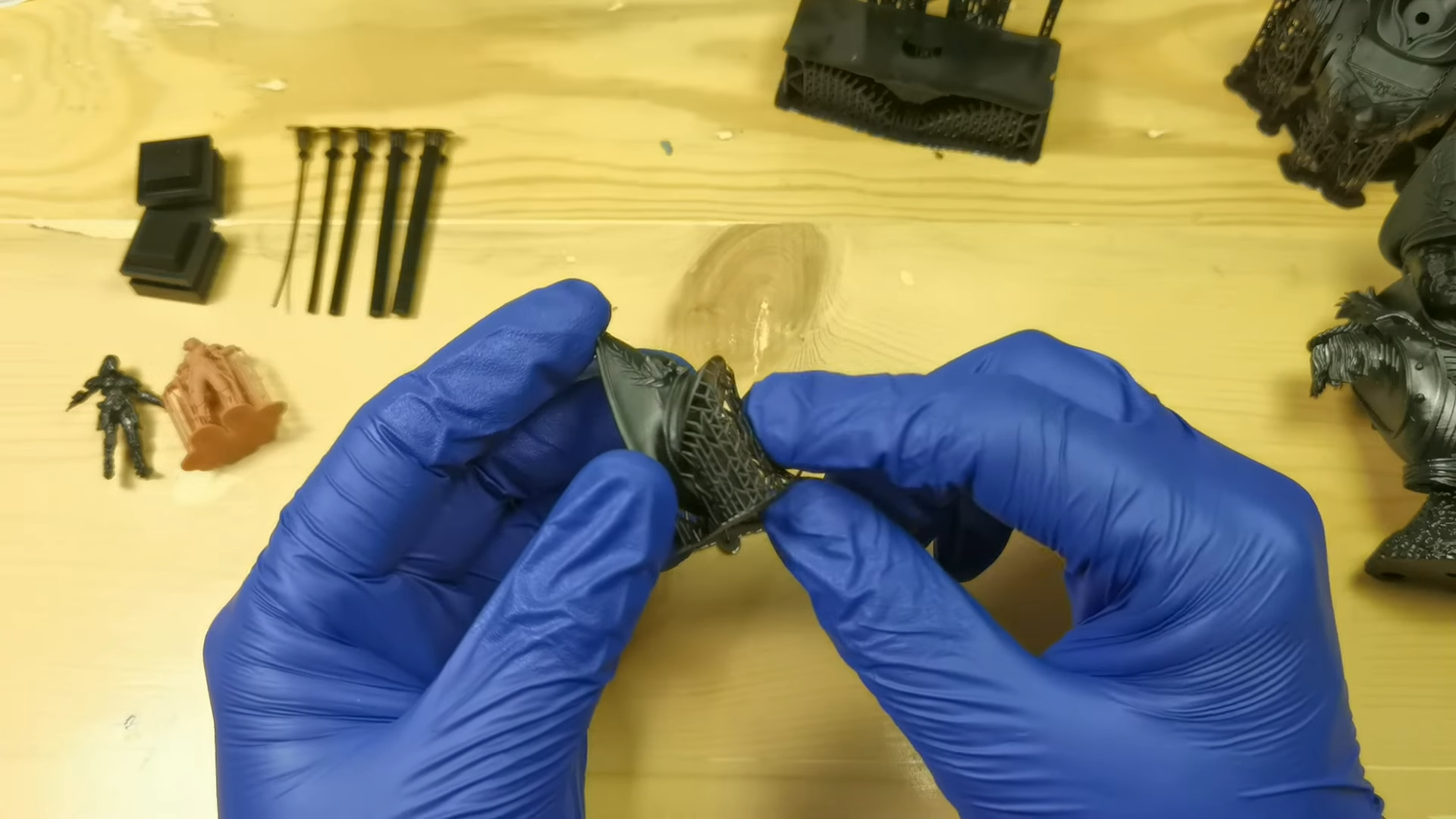

One of the first things that caught his attention was how soft and flexible models printed with the ONYX Impact Plus were before post-curing. Once thoroughly post-cured, it'll get stiffer, leaving just a little flex.

Excited as he was, it also means that his usual go-to supports are failing terribly when printing this resin.

Since the supports are flexible, he couldn't rely on his usual minimum support settings for these models. His first print had support failure and required some support adjustment. He found that the best support tip size for this resin is between 0.3–0.5 mm, with consideration of how big of a model you are printing. A small finger-size miniature could use a 0.3 mm, while something the size of your palm might require bigger and heavier support settings like the 0.5 mm.

Another thing that shocked him was the exposure time for the ONYX Impact Plus. Compared to the usual model resins that took 2–3 seconds of exposure time, this engineering resin needs a whopping 25 seconds of exposure time per layer. A number so big that he believes other resin would have already turned into a blob of mess if cured with the same exposure time.

However, as impressive as it is, it also means that printing with the ONYX Impact Plus took significantly way longer than his usual go-to model resins. A bust model that typically took him 6 hours with the Aqua-Gray 8K now required a staggering 26 hours when printed with the ONYX Impact Plus Resin.

Resin Torture Test

Dennys was known for his impeccably detailed torture test for both 3D printers and resins. And this resin is definitely going to be his next victim. But does it really break under his torture test? After all, he named it the unbreakable.

Bend Test

To complete the bend test, Dennys printed 5 sticks with different thicknesses and bent them one by one to check their elasticity.

To his surprise, not a single stick was broken. Each of the 5 bent significantly, shaping a tight U-shape, but none of them break. He even found the 4 mm and 5 mm ones to be incredibly hard to bend.

Drop Test

As the name implies, the drop test typically consists of dropping the models from the edge of the table, simulating an accidental drop during a heated tabletop game. Dennys used a small box and a mini for this test.

After dropping the models dozens of times from the edge of the table, he realized that it was not going to break anything. So, he brought the mini outside and started rampageously throwing and smacking it into the floor multiple times, to no use. The mini remains intact, looking all great and unscathed.

Impact Test

Inspired by the launch video of the ONYX Impact Plus, Dennys was compelled to print his own resin hammer. He wanted to prove himself that a mere resin-printed hammer could hammer down a real, metal nail, just like shown in the launch video.

However, he figured that he should have printed a different hammer shape as this one has too short of a handle he kept hitting the plank with his hand as the nail was going deeper.

Heat Test

Dennys was interested in how the resin would react when exposed to heat, so he warmed a couple of his sticks from the bend test with a hairdryer. The model becomes so flexible and soft like its pre-post-cured state. In addition, it holds its shape when it cools back down.

Separation Test

To wrap up his torture test, Dennys also left some of the liquid resin in a cup for 24 hours to see whether the pigment of the resin would separate and settle at the bottom. The next day, Dennys found the resin still looking like he left him yesterday.

In addition, he also mentioned that upon pouring the resin after vigorously shaking it, he almost didn't find any bubbles as the resin has an extremely high viscosity.

Should You Get the ONYX Impact Plus?

In Dennys' words, he thinks it's the strongest resin he has ever tested. It could easily hammer a metal nail without cracking and barely unscathed. The downside is perhaps the long printing time due to its 25s per layer exposure time. So unless you need to print something super tough, you might not want to wait that long.

That said, the communities are coming up with different ways to mix the ONYX Impact Plus with their all-time favorite resins. It gives a certain toughness and flexibility to their miniatures while still maintaining all the fine details. Best of all, it won't take the whole 26 hours to print out a 10 cm tall model.

Want to watch Dennys' torture test in full? Check out his video below: