讓我們花點時間欣賞一下上面的彩色樹脂 3D 打印件。使用樹脂,您可以將所有類型的 3D 打印創意變為現實。您最喜歡的 Marvel 角色,如鋼鐵俠、美國隊長、綠巨人和其他超級英雄,可以輕鬆打印出來並作為收藏品展示在您的家中、工作場所或任何您喜歡的地方。

但是,市場上有各種各樣的樹脂,您應該購買哪一種?

今天,我們將為您提供入門指南,讓您了解哪些Phrozen 樹脂最適合初學者和愛好者。

對於剛開始使用樹脂 3D 打印的用戶,我們推薦使用Aqua 系列(藍色、綠色、灰色 4K和象牙色 4K )、 類 ABS 系列( 啞光灰色、 乳白色)、 米色 Flex和透明樹脂的樹脂。

讓我們深入了解每種樹脂的特性和特性以及它們的用途:

水族系列

Aqua-Gray 4K 和 Aqua-Ivory 4K 樹脂 — 最適合極其精細的 3D 打印

冰雪水灰色 4K 和Aqua-Ivory 4K樹脂可創建分辨率極高的打印件,最適合打印表面光滑且無水平線條的高度複雜的 3D 打印模型。使用 Aqua-Gray 4K 樹脂,上面照片中的黑豹半身雕像打印了所有微小的細節,使 3D 打印盡可能具有紋理。

3D 模型來源: Loot Studios

3D 模型來源: Loot Studios

Aqua-Ivory 4K 顏色淺,非常適合塗上各種顏色,讓您的 3D 打印盡可能逼真。 Aqua-Ivory 4K 也非常適合在更大的 3D 打印機(例如 Sonic Mighty 4K 或 Sonic Mega 8K)的幫助下打印出大型和詳細的 3D 模型。

作為創客,如果您希望打印出具有極致細節且沒有水平線條的 3D 可打印模型,Aqua-Gray 4K 和 Aqua-Ivory 4K 樹脂將是您的最佳選擇。

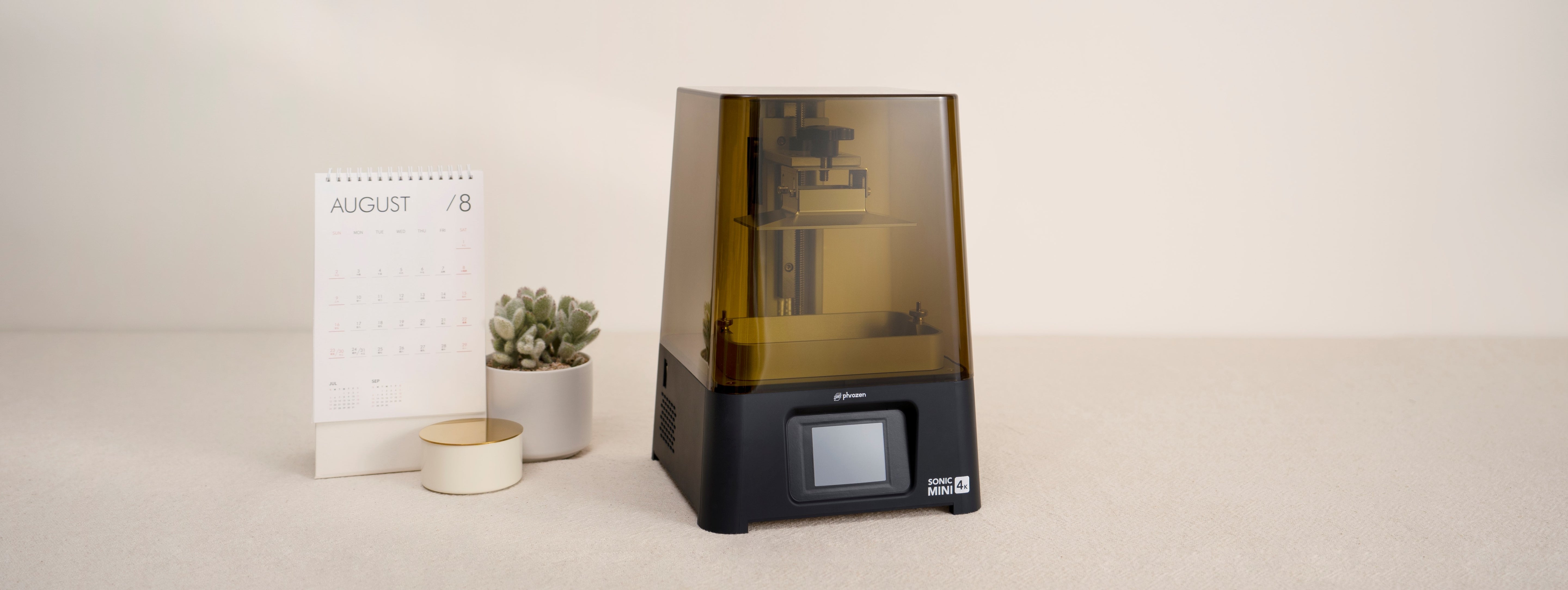

這種樹脂最適用於 Phrozen LCD 3D 打印機: Sonic Mini 4K 、 Sonic Mighty 4K和Sonic Mega 8K 。

特徵:

Phrozen 4K 樹脂可製作精度極高的 3D 模型。低粘度還便於在打印完成後沖洗和清潔 3D 打印件。

功能(水灰色 4K):

粘度:150cps

密度:1.1

Tg(玻璃化轉變溫度):68.4℃

表面硬度(邵氏 D):邵氏 77 D

伸長率(斷裂):7%

抗拉強度:2 Mpa

I-Zod 衝擊:6.78 KJ/m2

特點(Aqua-Ivory 4K):

粘度:221cps

密度:1.1

表面硬度(邵氏 D):邵氏 75 D

伸長率(斷裂):6%

抗拉強度:1.9 Mpa

水藍色和水綠色樹脂 - 最適合彩色 3D 打印

憑藉其鮮豔的色彩, Phrozen 水藍色樹脂和水綠色樹脂使製造商能夠打印出充滿活力和華麗的 3D 模型,從而迅速吸引人們的注意力。看看上面照片中用 Aqua-Green 樹脂打印的霸王龍。是不是顯得來勢洶洶,栩栩如生?

水藍色和水綠色樹脂可以為您的所有作品帶來流行色彩,而不是通常的中性樹脂顏色。作為獎勵,您無需在打印後為模型上色。

特徵:

Aqua-Blue 和 Aqua-Green 樹脂均可輕鬆創建不易碎的 3D 可打印模型。與 Aqua-Gray 4K 樹脂相比,Aqua-Blue 和 Aqua-Green 樹脂具有更高的拉伸強度或耐壓斷裂性。

這兩種樹脂在所有 Phrozen 樹脂中收縮率最低,非常適合高精度打印。 Aqua-Green 和 Aqua-Blue 樹脂的粘度均低於 Aqua-Gray 4K,但 Aqua-Green 的粘度略低於 Aqua-Blue 樹脂。

特點(水藍色):

粘度:130cps

密度:1.12

Tg(玻璃化轉變溫度):82℃

表面硬度(邵氏 D):邵氏 86 D

伸長率(斷裂):21%

抗拉強度:24 Mpa

I-Zod 衝擊:1.81KJ/m2

特點(水綠色):

粘度:125cps

密度:1.12

Tg(玻璃化轉變溫度):80℃

表面硬度(邵氏 D):邵氏 86 D

伸長率(斷裂):21%

抗拉強度:24 Mpa

I-Zod 衝擊:1.81KJ/m2

水灰色 8K 樹脂 - 極其複雜的 8K 質量 3D 打印的最佳選擇

Phrozen 的全新水灰色 8K 樹脂採用啞光灰色飾面,能夠以 8K 分辨率展示引人注目的細節,與Sonic Mini 8K 3D 打印機配合使用效果最佳。 Aqua-Gray 8K 可創建極其複雜和逼真的 3D 模型,看起來是專業製作的。

我們建議使用 Aqua-Gray 8K 樹脂製作各種高品質微型模型、戒指、精美珠寶等。

特徵:

Phrozen Aqua-Gray 8K 打造低收縮、高分辨率模型,具有一定的韌性。一旦您的 8K 質量 3D 打印準備就緒,它也非常容易沖洗和清潔。

特徵:

粘度:420 cps

密度:1.1克

表面硬度(邵氏 D):邵氏 85 D

伸長率:18%

抗拉強度:43.17 Mpa

I-Zod 衝擊:11.73 KJ/m2

類ABS系列

啞光灰色和乳白色 - 最適合繪畫

Phrozen Matte Grey 樹脂和Creamy White 樹脂顏色淺,非常適合希望打印中性色調模型的製造商。類 ABS 系列樹脂是 LCD 3D 打印使用最廣泛的樹脂之一,與所有其他 Phrozen 樹脂相比,目前打印成功率最高。

上圖中的模型是用類似 ABS 的乳白色樹脂打印的。看看純白色和紋理表面。這些樹脂 3D 模型可以很容易地塗上您喜歡的任何顏色,因為它可以用作底色。

特徵:

在所有 Phrozen 樹脂中,類 ABS 啞光灰色樹脂和乳白色樹脂的粘度最低,能夠製作堅固的高分辨率 3D 模型。

特性(類 ABS 啞光灰色):

粘度:67 cps

密度:1.1

Tg(玻璃化轉變溫度):70℃

表面硬度(邵氏 D):邵氏 76 D

伸長率(斷裂):3%

抗拉強度:10 Mpa

I-Zod 衝擊:1.44 KJ/m2

特性(ABS-like Creamy White):

粘度:77 cps

密度:1.1

Tg(玻璃化轉變溫度):70℃

表面硬度(邵氏 D):邵氏 79 D

伸長率(斷裂):2%

抗拉強度:12 Mpa

I-Zod 衝擊:2.32 KJ/m2

Beige Flex - 最適合原型製作

Beige Flex 樹脂顏色淺,也最適合打印中性色 3D 模型,由於其親水性表面,這些模型可以輕鬆塗漆。親水錶面很容易變濕,這意味著在樹脂乾燥後可以很容易地塗上油漆。這很重要,因為塑料樹脂有時很難塗漆。

您可以使用 Beige Flex 打印出帶有可移動部件的原型模型或 3D 模型,以表達您的創意。

特徵:

Beige Flex 具有極高的拉伸強度,這意味著使用這種樹脂打印的 3D 模型非常堅韌,不易折斷。

特徵:

粘度:540cps

密度:1.1

Tg(玻璃化轉變溫度):74℃

表面硬度(邵氏 D):邵氏 68 D

伸長率(斷裂):26%

抗拉強度:12 Mpa

I-Zod 衝擊:5.3 KJ/m2

泥狀樹脂 - 最適合帶有細節的充滿活力的 3D 打印

Phrozen Mud-like Resin具有引人注目的顏色和納米陶瓷顆粒,非常適合製作高品質和堅固的樹脂 3D 打印件。 Mud-like Resin 是創建具有逼真面部表情的 3D 模型的理想選擇,因為該樹脂具有啞光效果,可精確展示皮膚紋理、皺紋等。

我們建議使用這種樹脂來製作充滿活力和色彩繽紛的 3D 打印頭半身像和造型。

特徵:

Phrozen Mud-like Resin 具有極低的收縮率,因此您無需擔心您的 3D 模型在打印後會變形。

特徵:

粘度:360 cps

Tg(玻璃化轉變溫度):65℃

表面硬度(邵氏 D):邵氏 89 D

伸長率:9%

抗拉強度:32 Mpa

I-Zod 衝擊:6.5 KJ/m2

水色透明樹脂 - 最適合透明打印

Phrozen Aqua Clear 樹脂可創建高度透明的 3D 模型,這些模型在後固化過程後不會變黃。使用它,您可以根據需要打印各種透明的 3D 對象,例如 3D 收藏模型(如上圖中的鹿家族)、透明原型部件、光學部件和其他半透明模型。

您將需要對打印件進行後處理,以去除 3D 打印件上存在的任何層線,以獲得晶瑩剔透的效果。

特徵:

Aqua Clear Resin 生產的 3D 模型具有極高的耐熱性和高拉伸強度,因此 3D 打印件在壓力下不會輕易破裂。

特徵:

粘度 - 142cps

密度 - 1.1

Tg(玻璃化轉變溫度)- 73℃

表面硬度(邵氏 D)- 邵氏 70 D

伸長率(斷裂) - 17%

抗拉強度 - 12 Mpa

I-Zod 衝擊 - 2.68 KJ/m2

您已經了解了哪些 Phrozen 樹脂最適合初學者和發燒友的詳細分類。

請參考我們的樹脂配置文件圖表,了解如何為其他Phrozen 樹脂設置樹脂配置文件的一般概念。隨意進行調整以查看最適合您的方法。

查看我們之前的博文,其中解釋了哪些 Phrozen LCD 3D 打印機最適合初學者。

11條評論

YUGUO

Hi,I want to ask Aqua-Gray 8K Resin’s Tg (Glass Transition Temperature),THANKS

———

Phrozen Technology replied:

Hello Yuguo, Thank you for commenting.

The Tg of the material was not in both the standard testing programme of our resin product, and the expected using scenario of the material. Thus we are not able to provide the data of what you are looking for.

Thank you.

Best, Phrozen Team

>

Hi,I want to ask Aqua-Gray 8K Resin’s Tg (Glass Transition Temperature),THANKS

———

Phrozen Technology replied:

Hello Yuguo, Thank you for commenting.

The Tg of the material was not in both the standard testing programme of our resin product, and the expected using scenario of the material. Thus we are not able to provide the data of what you are looking for.

Thank you.

Best, Phrozen Team

>

Gasper

I plan to purchase complete workflow for Mega 8k S

Resin 1:

I want to print large parts for motorcycles – meaning they need to have paint ready smooth surface and must be temperature resistant up to around 90°C, UV resistant and material must be appropriate for outdoor use.

Parts printed will be monocoques – hollow, and will be filled with various foams – will inner surface be fully cured during printing process ?

Which resin to use?

Can resin be colored prior printing if we would like to have it black, but other colors would perform better?

Resin 2:

Manufacturing molds for composite parts (Carbon)

Should have very smooth surface and resistant to 130°C for two hours at 5 bar of pressure. If not avalable, what is closest to that, since we can adopt curing cycle a bit.

What resin to use? how to temper (increase temperature resistance) it?

I need to know what spare parts are needed for continious prining of parts.

All info about workflow are highly appreciated.

Thanks, Gasper

———

Phrozen Technology replied:

Hi Gasper,

1. Resin printed objects are having smooth surface overall, especially when anti-aliasing is enabled. To achieve a smooth surface in resin printing depends on model design, orientation, and print parameters. Proper model preparation, orientation, and resin settings are crucial for optimal results.

2. For outdoor use, consider applying a UV-resistant prime spray after printing. Heat-resistant resins like Phrozen TR300 are suitable. However, the actual outdoor performance can be affected by complex environmental factors.

3. Hollow prints can be achieved through model design or settings in slicer software. Cure the interior part of a printed object with UV light of the same wavelength as post-curing is a necessary. Objects with uncured interiors may deform or break.

4. Based on your description, our initial judgment will recommend the Phrozen TR300 resin for its balance of properties.

5. Resin colouring is typically done after printing using paints or dyes. Each resin has its inherent colour; for example, TR300 is black, therefore the objects printed out using TR300 will be black.

6. TR300 has a heat deflection temperature of 156°C, suitable for industrial prototyping. For higher temperature resistance, consider Phrozen Dental Ortho Model Resin (190°C) or Ceramic White Resin which also has outstanding wear resistance, durability and temperature resistance.

7. Heat resistance is intrinsic to the resin’s material properties and can’t be externally altered.

8. For a printing farm, we suggest to keep extra releasing film, resin, and LCD screens. Use protective films on LCDs to prevent damage from resin leakage. Maintain stable humidity, temperature, and good ventilation in your working environment.

Feel free to contact our customer support for further assistance or detailed workflow information.

Best regards, Phrozen Team

>

I plan to purchase complete workflow for Mega 8k S

Resin 1:

I want to print large parts for motorcycles – meaning they need to have paint ready smooth surface and must be temperature resistant up to around 90°C, UV resistant and material must be appropriate for outdoor use.

Parts printed will be monocoques – hollow, and will be filled with various foams – will inner surface be fully cured during printing process ?

Which resin to use?

Can resin be colored prior printing if we would like to have it black, but other colors would perform better?

Resin 2:

Manufacturing molds for composite parts (Carbon)

Should have very smooth surface and resistant to 130°C for two hours at 5 bar of pressure. If not avalable, what is closest to that, since we can adopt curing cycle a bit.

What resin to use? how to temper (increase temperature resistance) it?

I need to know what spare parts are needed for continious prining of parts.

All info about workflow are highly appreciated.

Thanks, Gasper

———

Phrozen Technology replied:

Hi Gasper,

1. Resin printed objects are having smooth surface overall, especially when anti-aliasing is enabled. To achieve a smooth surface in resin printing depends on model design, orientation, and print parameters. Proper model preparation, orientation, and resin settings are crucial for optimal results.

2. For outdoor use, consider applying a UV-resistant prime spray after printing. Heat-resistant resins like Phrozen TR300 are suitable. However, the actual outdoor performance can be affected by complex environmental factors.

3. Hollow prints can be achieved through model design or settings in slicer software. Cure the interior part of a printed object with UV light of the same wavelength as post-curing is a necessary. Objects with uncured interiors may deform or break.

4. Based on your description, our initial judgment will recommend the Phrozen TR300 resin for its balance of properties.

5. Resin colouring is typically done after printing using paints or dyes. Each resin has its inherent colour; for example, TR300 is black, therefore the objects printed out using TR300 will be black.

6. TR300 has a heat deflection temperature of 156°C, suitable for industrial prototyping. For higher temperature resistance, consider Phrozen Dental Ortho Model Resin (190°C) or Ceramic White Resin which also has outstanding wear resistance, durability and temperature resistance.

7. Heat resistance is intrinsic to the resin’s material properties and can’t be externally altered.

8. For a printing farm, we suggest to keep extra releasing film, resin, and LCD screens. Use protective films on LCDs to prevent damage from resin leakage. Maintain stable humidity, temperature, and good ventilation in your working environment.

Feel free to contact our customer support for further assistance or detailed workflow information.

Best regards, Phrozen Team

>

Massimo

I have dental lab. I produce ,just dental cast for orthodontic aligner. I have two machines: sonic 4k xl plus and sonic mega 8k. Which resin is economic for these printers.

Regards

———

Phrozen Technology replied:

Hello Massimo,

Thank you for commenting. For dental products, please contact our dental product agent to get further information and assistance, by submit a request via this link.

https://dental.phrozen3d.com/pages/contact

Hope this helps and have a great day.

Best, Phrozen Team

>

I have dental lab. I produce ,just dental cast for orthodontic aligner. I have two machines: sonic 4k xl plus and sonic mega 8k. Which resin is economic for these printers.

Regards

———

Phrozen Technology replied:

Hello Massimo,

Thank you for commenting. For dental products, please contact our dental product agent to get further information and assistance, by submit a request via this link.

https://dental.phrozen3d.com/pages/contact

Hope this helps and have a great day.

Best, Phrozen Team

>

Dave Dening

I just finished my first print with TR300 using an Egloo Mars Pro. I’m impressed by the resin’s toughness in snapping off the supports. But, in cleaning up the printer there was a sticky layer even after a wash in 99% isopropyl alcohol. And, the prints were sticky even after a quick wash.

What can I use to clean off the resin left on the printer?

———

Phrozen Technology replied:

Hi Dave,

For cleaning the leftover resin, we recommend our customers to follow these steps. Firstly, spray 95% sanitizing alcohol, IPA onto the FEP or the PFA (nFEP) film. Then, use a soft kitchen paper towel or fiber cloth to clean the leftover resin. Repeat this step until the resin vat is clean and make sure to clean the edges as well. This will ensure that the resin vat is thoroughly cleaned and ready for the next use.

If you see cured resin particles scattered around the vat, please check your printer’s manual, and see if you can find any function like the vat cleaning that we provided with our printers. You can check out this article about vat cleaning function in our helpcentre: https://reurl.cc/pLgZW8

Hope you find this helpful!

Regards, Phrozen Team.

>

I just finished my first print with TR300 using an Egloo Mars Pro. I’m impressed by the resin’s toughness in snapping off the supports. But, in cleaning up the printer there was a sticky layer even after a wash in 99% isopropyl alcohol. And, the prints were sticky even after a quick wash.

What can I use to clean off the resin left on the printer?

———

Phrozen Technology replied:

Hi Dave,

For cleaning the leftover resin, we recommend our customers to follow these steps. Firstly, spray 95% sanitizing alcohol, IPA onto the FEP or the PFA (nFEP) film. Then, use a soft kitchen paper towel or fiber cloth to clean the leftover resin. Repeat this step until the resin vat is clean and make sure to clean the edges as well. This will ensure that the resin vat is thoroughly cleaned and ready for the next use.

If you see cured resin particles scattered around the vat, please check your printer’s manual, and see if you can find any function like the vat cleaning that we provided with our printers. You can check out this article about vat cleaning function in our helpcentre: https://reurl.cc/pLgZW8

Hope you find this helpful!

Regards, Phrozen Team.

>

Michael Lindsay

Hi,

I’m looking for a very opaque bright white resin. I’ve tried a few different brands but they do not print with enough detail (similar to the grey abs like). Some voids are filled in making the prints unusable for what I need them for.

Why are the grey resins the most suited to detailed prints? Is it due to the pigments blocking the excess light more efficiently or am I simply using the wrong settings.

Thanks

———

Phrozen Technology replied:

Hi Michael, if you are looking for gray resins that offer the highest result of details, then we recommend the Aqua-Gray 8K. You may also look into our Aqua-Gray 4K for another gray option or the BASF Protowhite for a bright, clean white resin.

Cheers, Phrozen Team

>

Hi,

I’m looking for a very opaque bright white resin. I’ve tried a few different brands but they do not print with enough detail (similar to the grey abs like). Some voids are filled in making the prints unusable for what I need them for.

Why are the grey resins the most suited to detailed prints? Is it due to the pigments blocking the excess light more efficiently or am I simply using the wrong settings.

Thanks

———

Phrozen Technology replied:

Hi Michael, if you are looking for gray resins that offer the highest result of details, then we recommend the Aqua-Gray 8K. You may also look into our Aqua-Gray 4K for another gray option or the BASF Protowhite for a bright, clean white resin.

Cheers, Phrozen Team

>

Shaneel

Hi,

What is the post curing time required for the resins TR300 & TR250 ?

———

Phrozen Technology replied:

Hi Shaneel, thanks for your comment! Please post-cure both TR300 & TR250 for at least 30 minutes to ensure the models are thoroughly cured.

Cheers, Phrozen Team

>

Hi,

What is the post curing time required for the resins TR300 & TR250 ?

———

Phrozen Technology replied:

Hi Shaneel, thanks for your comment! Please post-cure both TR300 & TR250 for at least 30 minutes to ensure the models are thoroughly cured.

Cheers, Phrozen Team

>

IRMAK

Hi, which resin is the most suitable for making the most durable/flexible 3D printed figurines or busts that will have a long shelf life?

———

Phrozen Technology replied:

Hey IRMAK,

Thank you for your comment! For best results, we would recommend Aqua-Gray 4K resin.

Cheers, Phrozen Team

Hi, which resin is the most suitable for making the most durable/flexible 3D printed figurines or busts that will have a long shelf life?

———

Phrozen Technology replied:

Hey IRMAK,

Thank you for your comment! For best results, we would recommend Aqua-Gray 4K resin.

Cheers, Phrozen Team

RAMI MOSLEM

What is suitable settings (Resin Profile) for using Washable Dental Models resin for producing high quality dental models and ditched dies using Sonic Mini 4K?

———

Phrozen Technology replied:

Hi there,

Thank you for your comment. Please refer to our resin profile page to find the answer to your question: https://phrozen3d.com/pages/resin-profile

What is suitable settings (Resin Profile) for using Washable Dental Models resin for producing high quality dental models and ditched dies using Sonic Mini 4K?

———

Phrozen Technology replied:

Hi there,

Thank you for your comment. Please refer to our resin profile page to find the answer to your question: https://phrozen3d.com/pages/resin-profile

Isaac

Hi, which resin would be best suited for printing very large parts (full build platforms on the Mega) that will be assembled / glued together to form a larger model? Specifically which resin would have the lowest deformation after curing so that alignment between pieces is easier?

Thanks,

———

Phrozen Technology replied:

Hi there,

Thank you for your comment! If you’re planning on printing out Industrial parts, we would recommend TR300 Resin. If you’re looking to print out action figurines or other 3D prints, we would recommend Aqua-Gray 4K or Aqua-Ivory 4K Resin.

Hi, which resin would be best suited for printing very large parts (full build platforms on the Mega) that will be assembled / glued together to form a larger model? Specifically which resin would have the lowest deformation after curing so that alignment between pieces is easier?

Thanks,

———

Phrozen Technology replied:

Hi there,

Thank you for your comment! If you’re planning on printing out Industrial parts, we would recommend TR300 Resin. If you’re looking to print out action figurines or other 3D prints, we would recommend Aqua-Gray 4K or Aqua-Ivory 4K Resin.

Phrozen Team

Hi there, thank you for your comment!

“ABS” stands for Acrylonitrile butadiene styrene which is a chemical compound used to create resins. Please refer to this link to learn more about our functional resins: https://phrozen3d.com/collections/functional-resins

Hi there, thank you for your comment!

“ABS” stands for Acrylonitrile butadiene styrene which is a chemical compound used to create resins. Please refer to this link to learn more about our functional resins: https://phrozen3d.com/collections/functional-resins

Bo R McCullough

This is very informative. What does ‘ABS’ stand for and which resins work best for applications requiring some flexibility?

This is very informative. What does ‘ABS’ stand for and which resins work best for applications requiring some flexibility?