樹脂 3D 列印最受歡迎的用途之一可能是列印您自己的桌上遊戲雕像和微縮模型收藏。多年來,創作者一直在尋找方法,在樹脂列印 3D 模型上實現盡可能高的分辨率,同時提高耐用性。

眾所周知,3D 列印樹脂模型非常脆且容易破裂。這導致網路上出現了無數的3D 列印文章,提供有關如何使樹脂列印的3D 模型不易損壞的提示和技巧,包括在不太乾燥或太冷的良好控制環境中工作、縮短與異丙醇的接觸時間,甚至一系列複雜的設定來調整您的列印參數。所有這些確實都是很好的 3D 列印建議,但是,透過使用正確的樹脂來實現您想要的結果可以輕鬆解決這個問題。在這種情況下,需要使用更堅固、更耐用的 3D 樹脂。

幾個月前,Phrozen 發布了新的ONYX Impact Plus Resin 。這種樹脂能夠承受比其他樹脂強五倍的衝擊,具有其他商業樹脂中很少有的令人難以置信的強度和耐用性。不幸的是,由於其高黏度,使用這種 3D 列印樹脂也更難實現最高的細節,因為它需要更厚的層高來列印。

ONYX Impact Plus最初設計用於重型列印和工程應用。 ONYX Impact Plus Resin誕生於 Phrozen 與 Loctite® 的合作關係,可列印高彈性、可彎曲且可扭曲的物體,這種品質在用於微型模型或其他展示物體的樹脂上很少出現。

我們的一些團隊專家立即意識到ONYX Impact Plus 樹脂令人難以置信的耐用性,並開始進行實驗。

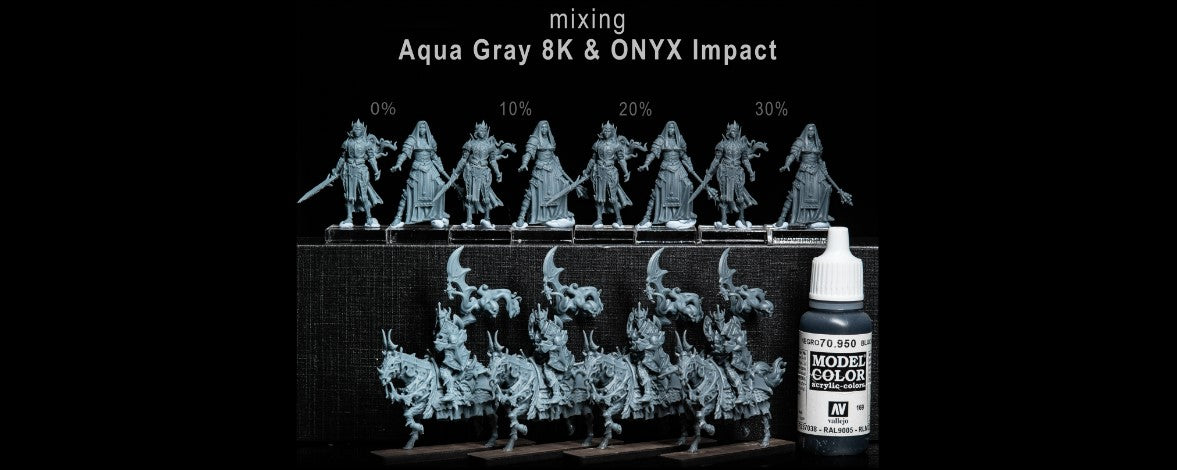

為了創造更堅固、更耐用的 3D 列印件,同時仍保持盡可能高的分辨率,我們的團隊專家將ONYX Impact Plus與Aqua-Gray 8K結合。結果?令人興奮!

深入探討水灰色 8K與ONYX Impact Plus 的混合!

Maria ZN測試了不同的Aqua-Gray 8K和ONYX Impact Plus混合物,以找到最佳比例。她在所有測試中使用相同的模型來保持一致性,而無需打開抗鋸齒功能。請繼續關注直到最後看到她的設置,讓我們看看她對這個樹脂組合有什麼看法。

細節

與使用Aqua-Gray 8K列印的模型相比,使用混合樹脂列印的模型在細節層面上幾乎沒有明顯差異。這意味著這種樹脂組合絕對是同時實現高解析度和耐用性的好方法。

對於 20% 的混合,解決方案是將曝光時間增加到 3.1 秒,並將提升速度保持在 45 - 它允許我列印具有相對較大橫截面的 75 毫米迷你模型,而無需層移位。細節看起來和2.8s一樣好。

圖層移動

當使用兩步驟運動控制 (TSMC) 以 60 和 150 的提升速度列印ONYX Impact Plus樹脂比例為 0%、10% 和 20% 的混合樹脂時,某些模型可能會出現層移位。 20% 混合的層移位的解決方案是將曝光時間增加到 3.1 秒,並將提升速度保持在 45。

對於 30% 的混合,透過 TSMC 將提升速度降低至 45 和 150,顯示出一個有希望的結果,列印件的偏移明顯少於其他方案。話雖如此,使用ONYX Impact Plus和Aqua-Gray 8K樹脂混合物成功列印的關鍵是降低提升速度或增加支撐密度。

列印時間

在混合物中添加 10%-20% 的ONYX Impact Plus時,列印時間會略有增加。但是,這取決於您的型號以及是否需要較慢的提升速度和較短的休息時間。 Maria的測試表明,混合了 30% 的ONYX Impact Plus後,與使用純Aqua-Gray 8K列印相比,列印時間延長了近 50%。

耐用性

每增加 10% 的ONYX Impact Plus ,模型就會變得更靈活、更不易碎、更難破損。 Maria透過在她的 3D 列印模型上折斷一些鞭子和長矛來展示混合的力量。在影片中,我們可以看到,隨著ONYX Impact Plus添加到混合物中的百分比增加,需要付出更多的努力來打破模型。

以下是瑪麗亞的建議:

- 10% - 最適合不經常處理的顯示型號和遊戲型號。

- 20% - 最適合一般迷你遊戲

- 30% - 對於需要經常操作的模型來說是最佳選擇,因為它的耐用性非常好。

尋找適合微縮模型和桌上戰爭遊戲的完美樹脂混合物

Eric Festa也對這種樹脂組合進行了一些實驗,以便找到他的 3D 列印樹脂微縮模型的最佳比例。由於他的大部分微縮模型都受到桌上戰爭遊戲的啟發,因此他希望為極其詳細和高分辨率的微縮模型找到最佳比例,並且在處理時不會輕易損壞,這也就不足為奇了。

結果呢? Eric發現,對於微型模型來說, Aqua-Gray 8K和ONYX Impact Plus 的最佳比例是 4:1。每 4 克Aqua-Gray 8K需要 1 克ONYX Impact Plus 。在下面的影片中觀看他的極限彎曲測試,看看這種樹脂組合的彈性如何:

與 Eric 不同, Luther Caudle最喜歡的 3D 列印微型模型組合是 6 個Aqua-Gray 8K到 4 個ONYX Impact Plus 。他提到這種混合比例非常適合微型模型等較小的模型。他喜歡這種混合物的強度和靈活性,但發現較大的混合物存在一些問題,因為它們可能需要更多的支撐來平衡較軟的樹脂。但總的來說,他非常喜歡這種組合,以至於他現在印製的所有東西都是用它!觀看Luther 測試 ONYX Impact Plus 和 Aqua-Gray 8K 樹脂混合物的性能!

與Maria的發現類似,與純Aqua-Gray 8K相比, ONYX Impact Plus和Aqua-Gray 8K混合物需要更長的曝光時間和更慢的收縮速度,因為混合物具有更高的黏度。為了找到適合他的混音的設置, Luther列印了一些曝光測試,並注意模型的列印方式。從那裡,他稍微調整設定並檢查暴露測試的結果,看看結果是否有改善。

正確的參數設定

調整樹脂設定以適應您的列印習慣和環境可能具有挑戰性,尤其是對於這些混合樹脂,因為您沒有製造商通常提供的原始樹脂配置文件。但對於這些混音,不用擔心, Maria 、 Eric和Luther會為您提供支援!

Maria 的各種混合比的樹脂設置

Eric 的 1:4 ONYX Impact Plus和Aqua-Gray 8K Mix 的 Festa Slice 設置

Luther 對 60/40 比例的設置

您應該混合樹脂嗎?

儘管混合樹脂可能非常棘手,並且需要一定程度的專業知識才能正確完成,但這可能是實現您想要的樹脂性能的真正好方法。只需確保使用XP Finder等曝光測試工具進行大量測試並進行相應調整即可。找到適合您的樹脂混合物和環境的完美設定可能需要一些時間,因此請耐心等待,不要放棄。因為當你最終得到正確的結果時,這絕對是有史以來最令人滿意的感覺之一!

但感謝我們的團隊專家Maria 、 Eric和Luther ,您可以以他們的設定為基礎開始工作,而不是從零開始!您有興趣嘗試這種樹脂組合嗎?您認為哪一種比例最適合您?請在下面的評論中告訴我們!

———

特別感謝Maria ZN 、 Eric Festa和Luther Caudle分享他們的專業知識!請務必查看他們的帳戶,了解更多他們的作品,並獲取最新的提示和技巧,以提高您的樹脂 3D 列印技能!

6條評論

tony

How long do you suggesting curing the 20% mix in my wash and cure kit

———

Phrozen Technology replied:

Hello Tony, Thank you for commenting.

For Auqa 8K series resin, we recommend 30 minutes of post curing time. Thus we’d suggest you start with 30 minutes of post curing time for the mixture.

Hope this helps.

Best, Phrozen Team

>

How long do you suggesting curing the 20% mix in my wash and cure kit

———

Phrozen Technology replied:

Hello Tony, Thank you for commenting.

For Auqa 8K series resin, we recommend 30 minutes of post curing time. Thus we’d suggest you start with 30 minutes of post curing time for the mixture.

Hope this helps.

Best, Phrozen Team

>

Jamie

Phrozen, it would be awesome if you all are working on a purpose-made product like this that we could use right out of the bottle – hopefully one that would be equally suitable for small scales like 15mm or even 6mm as well as larger scales. 3D printing opens up a lot of new possibilities for me as a wargamer, but with everything there is to learn it can also quickly take over my hobby time. I look for solutions that are as ready out of the box as possible so that I can still have time to actually paint and play with the models I print.

———

Phrozen Technology replied:

Hi Jamie,

Thanks for your insightful comment! We’ve noticed the community’s interest in ready-to-use 3D printing solutions for miniatures. We’re actively researching and testing products that cater to various scales, making the process more convenient for hobbyists like you. Your feedback is invaluable as we work towards enhancing the 3D printing experience. Please stay tuned for updates!

Best, Phrozen Team

Phrozen, it would be awesome if you all are working on a purpose-made product like this that we could use right out of the bottle – hopefully one that would be equally suitable for small scales like 15mm or even 6mm as well as larger scales. 3D printing opens up a lot of new possibilities for me as a wargamer, but with everything there is to learn it can also quickly take over my hobby time. I look for solutions that are as ready out of the box as possible so that I can still have time to actually paint and play with the models I print.

———

Phrozen Technology replied:

Hi Jamie,

Thanks for your insightful comment! We’ve noticed the community’s interest in ready-to-use 3D printing solutions for miniatures. We’re actively researching and testing products that cater to various scales, making the process more convenient for hobbyists like you. Your feedback is invaluable as we work towards enhancing the 3D printing experience. Please stay tuned for updates!

Best, Phrozen Team

Timothy D.

How are the ratios measured? By volume or mass?

———

Phrozen Technology replied:

Hello Timothy,

Thank you for commenting. We’re measuring the ratios by using measuring cup when mixing it, so it should be by volume.

Hope this helps.

Best, Phrozen Team

>

How are the ratios measured? By volume or mass?

———

Phrozen Technology replied:

Hello Timothy,

Thank you for commenting. We’re measuring the ratios by using measuring cup when mixing it, so it should be by volume.

Hope this helps.

Best, Phrozen Team

>

Matthew Bonett

Hello Phrozen,

Interesting tutorial. I got a bottle of both aqua grey 8k and onyx impact plus and tried Luther’s 60/40 mix using the same printer settings. I got excellent results with the XP finder and RP tester, however when I tried printing pre-supported models I was not getting the same results. The raft prints and adheres to the plate but the supports adhere to the ACF film and am about to give up.

———

Phrozen Technology replied:

Hello Matthew,

Thank you for your comment. In this situation, we will suggest you to longer the exposure time for normal layer to see if the support can adhere to the raft.

Hope this helps.

Best, Phrozen Team.

>

Hello Phrozen,

Interesting tutorial. I got a bottle of both aqua grey 8k and onyx impact plus and tried Luther’s 60/40 mix using the same printer settings. I got excellent results with the XP finder and RP tester, however when I tried printing pre-supported models I was not getting the same results. The raft prints and adheres to the plate but the supports adhere to the ACF film and am about to give up.

———

Phrozen Technology replied:

Hello Matthew,

Thank you for your comment. In this situation, we will suggest you to longer the exposure time for normal layer to see if the support can adhere to the raft.

Hope this helps.

Best, Phrozen Team.

>

Milos

Hello Phrozen, can the resin-mixture stay in the bottle for some time?

When the right ratio and settings are stored as a profile, it would be great to just use the already prepared „cocktail“ from the bottle…

———

Phrozen Technology replied:

Hello Milos,

Thank you for your comment. Although mixing resin has been popular among the members in our community for quite some time, and experience shows that the well-liked Aqua Gray 8k plus Onyx Impact Plus formula is pretty stable, we will still suggest our users to mix just amount of resin they are going to print, and leave those two bottles of resin being separated for the rest of time.

The chemical reaction when mixing up those two ingredients is still unknown, we cannot be sure about would those which have already been mixed up can stay the quality as its initial state after times of standing. It is fun and challenging when making this kind of “homebrew” or “cocktail” style of resin and see what will happen, but since its ingredient is no longer the same as the one that comes out from the factory, we cannot guarantee its quality thus cannot recommend you to mix them up and just leave it there for a long time.

This question is both interesting and important. Thank you again for asking and we wish you an amazing printing journey.

Best, Phrozen Team

Hello Phrozen, can the resin-mixture stay in the bottle for some time?

When the right ratio and settings are stored as a profile, it would be great to just use the already prepared „cocktail“ from the bottle…

———

Phrozen Technology replied:

Hello Milos,

Thank you for your comment. Although mixing resin has been popular among the members in our community for quite some time, and experience shows that the well-liked Aqua Gray 8k plus Onyx Impact Plus formula is pretty stable, we will still suggest our users to mix just amount of resin they are going to print, and leave those two bottles of resin being separated for the rest of time.

The chemical reaction when mixing up those two ingredients is still unknown, we cannot be sure about would those which have already been mixed up can stay the quality as its initial state after times of standing. It is fun and challenging when making this kind of “homebrew” or “cocktail” style of resin and see what will happen, but since its ingredient is no longer the same as the one that comes out from the factory, we cannot guarantee its quality thus cannot recommend you to mix them up and just leave it there for a long time.

This question is both interesting and important. Thank you again for asking and we wish you an amazing printing journey.

Best, Phrozen Team

Jorge

What’s are the names of the cleric minatures?

———

Phrozen Technology replied:

Hello Jorge, thank you for asking. Those models printed out by Maria are from Loot Studios and Archvillain Games. For the specific model’s name, we suggest you to contact with the designers to get a correct answer. Best, Phrozen.

What’s are the names of the cleric minatures?

———

Phrozen Technology replied:

Hello Jorge, thank you for asking. Those models printed out by Maria are from Loot Studios and Archvillain Games. For the specific model’s name, we suggest you to contact with the designers to get a correct answer. Best, Phrozen.