One of the most popular uses of resin 3D printing is perhaps to print out your own collection of figurines and miniatures for tabletop gaming. Over the years, creators have been looking for ways to achieve the highest resolution possible on a resin printed 3D models while enhancing durability.

It is no secret that 3D printed resin models can be quite brittle and easy to break. This has resulted in countless 3D printing articles online providing tips and tricks on how to make your resin printed 3D models less fragile, including working in a well-controlled environment that are not too dry nor too cold, shortening contact time with isopropyl alcohol, even a series of complex settings to tweak your printing parameters. All of them are indeed great 3D printing advice, however, it could easily be solved by using the right resin to achieve the result you want. In this case, a stronger and more durable 3D resin.

A few months ago, Phrozen released its new ONYX Impact Plus Resin. Created to survive impact up to five times stronger than others, this resin offers incredible strength and durability that are rarely present in other commercial resins. Unfortunately, due to its high viscosity, it's also harder to achieve the highest detail with this 3D printing resin as it requires a thicker layer height to print.

The ONYX Impact Plus is initially designed for heavy-duty prints and engineering applications. Born from Phrozen's partnership with Loctite®, the ONYX Impact Plus Resin prints highly resilient, bendable, and twistable objects, a quality that is rarely present on resin for miniatures or other display objects.

Some of our group experts immediately realized the incredible durability of the ONYX Impact Plus Resin and started experimenting.

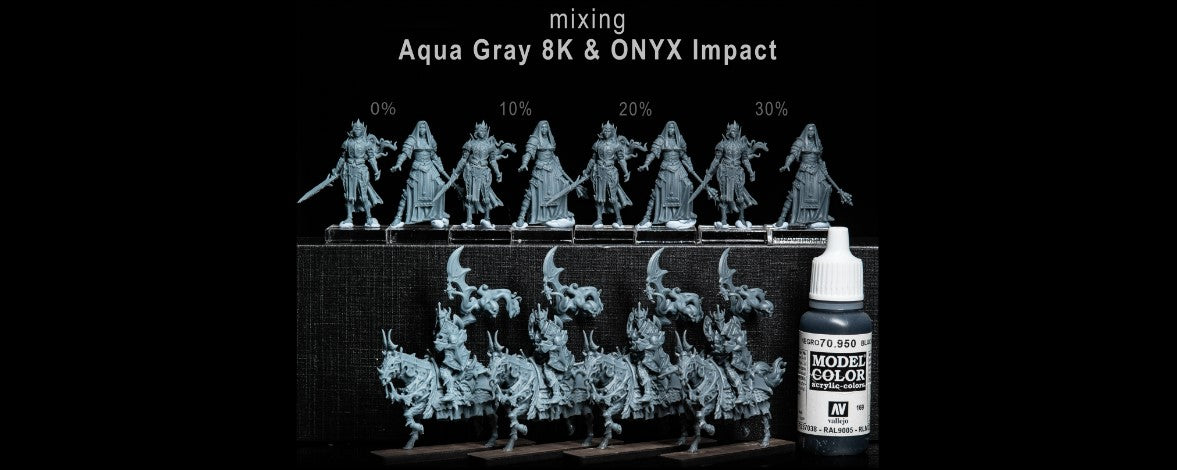

To create stronger and more durable 3D prints while still maintaining the highest resolution possible, our group experts combine the ONYX Impact Plus with Aqua-Gray 8K. The results? Mindblowing!

A Deep Dive on Mixing Aqua-Gray 8K with ONYX Impact Plus!

Maria ZN tested different Aqua-Gray 8K and ONYX Impact Plus mixes to find the most optimum ratio. She used the same models for all of her tests to maintain consistency without turning on anti-aliasing. Stay tuned until the end to see her settings and let's see what she's got to say about this resin combo.

Details

The models printed with the mixed resin show almost no visible difference in the level of detail when compared to the ones printed with Aqua-Gray 8K. It means that this resin combo is definitely a great way to achieve both high resolution and durability at the same time.

For the 20% mix the solution was to increase the exposure time to 3.1s and keep the lifting speed at 45 - it allowed me to print 75mm minis with a relatively large cross section without layer shifts. The details looked as good as 2.8s.

Layer Shifts

Layer shifts might appear on some models when printing the mixed resin with 0%, 10%, and 20% ratio of ONYX Impact Plus resin at lifting speeds of 60 and 150 with two steps motion control (TSMC). The solution for the layer shifts on the 20% mix would be to increase the exposure time to 3.1 s and keep the lifting speed at 45.

For the 30% mix, lowering the lifting speed to 45 and 150 with TSMC shows a promising result with significantly fewer shifts in the prints than the others. With that said, the key to a successfull print with ONYX Impact Plus and Aqua-Gray 8K resin mix is to lower your lifting speed or increase the support density.

Printing Time

There's a slight increase in printing time when adding 10%-20% of ONYX Impact Plus to the mix. However, it depends on your models and whether it would need a slower lifting speed and lower rest time. With 30% of ONYX Impact Plus on the mix, Maria's test shows almost 50% longer printing time compared to when printing with pure Aqua-Gray 8K.

Durability

With every 10% of ONYX Impact Plus added to the mix, the models become more flexible, less brittle, and harder to break. Maria shows the strength of the mix by snapping some whips and spears on her 3D printed miniatures. On the videos, we can see that with the increase in percentages of ONYX Impact Plus added to the mix, it requires more effort to break the models.

Below are Maria's recommendations:

- 10% - best for display models and gaming models that don’t get handled a lot.

- 20% - best for average gaming mini

- 30% - best choice for models that get handled a lot as it holds up really well.

Finding the Perfect Resin Mix for Miniatures and Tabletop Wargaming

Eric Festa also did some experiments with this resin combo in order to find the best ratio for his 3D printed resin miniatures. With most of his miniatures inspired by tabletop wargaming, it's no surprise that he would want to find the best ratio possible for extremely detailed and high-resolution miniatures that won’t easily break when handled.

The result? Eric found that the best Aqua-Gray 8K and ONYX Impact Plus ratio for miniatures are 4:1. It’s one gram of ONYX Impact Plus for every 4g of Aqua-Gray 8K. Take a look at his extreme flex test to see how resilient this resin combo is in the video below:

Unlike Eric, Luther Caudle's favorite mix for 3D printing miniatures is 6 Aqua-Gray 8K to 4 ONYX Impact Plus. He mentioned that this mix ratio works well for smaller models like miniatures. He loves the strength and flexibility of this mix but has found some issues with the larger ones, as they might require more supports to even out the softer resins. But overall, he loves the mix so much that it's everything he is printing with these days! Watch Luther's tests on how the ONYX Impact Plus and Aqua-Gray 8K resin mix performs!

Similar to Maria’s finds, the ONYX Impact Plus and Aqua-Gray 8K mix requires longer exposure time and slower retract speed compared to pure Aqua-Gray 8K due to the mix having a higher viscosity. To find the right settings for his mix, Luther prints out a couple of exposure tests and pays attention to how the models are printed. From there, he tweaks the settings a little and checks the results of the exposure tests to see if the results improve.

The Right Parameter Settings

Tweaking resins settings to suit your printing habits and environments might be challenging, especially for these mixed resins, as you don’t have the original resin profiles that are often provided by the manufacturer. But for these mixes, don’t worry as Maria, Eric, and Luther got your back!

Maria's Resin Settings for Various Mixing Ratio

Eric's Festa Slice Settings of 1:4 ONYX Impact Plus and Aqua-Gray 8K Mix

Luther's Settings for 60/40 Ratio

Should You Mix Your Resins?

Although mixing resin can be very tricky and require some level of expertise to get it right, it could be a really great way to achieve the properties you want from a resin. Just make sure to do a lot of tests with exposure test tools like the XP Finder and tweak it accordingly. Finding the perfect settings for your resin mix and environment might take some time, so be patient and don't give up. Because when you finally get it right, it's definitely one of the most satisfying feelings ever!

But thanks to our group experts like Maria, Eric, and Luther, you can start working your perfect settings with theirs as a base instead of going from zero! Are you interested in trying this resin combo? Which ratio do you think will work best for you? Let us know in the comment below!

———

Special thanks to Maria ZN, Eric Festa, and Luther Caudle for sharing their expertise! Make sure to check out their accounts to see more of their works and get the latest tips and tricks to enhance your resin 3D printing skills!

6條評論

tony

How long do you suggesting curing the 20% mix in my wash and cure kit

———

Phrozen Technology replied:

Hello Tony, Thank you for commenting.

For Auqa 8K series resin, we recommend 30 minutes of post curing time. Thus we’d suggest you start with 30 minutes of post curing time for the mixture.

Hope this helps.

Best, Phrozen Team

>

How long do you suggesting curing the 20% mix in my wash and cure kit

———

Phrozen Technology replied:

Hello Tony, Thank you for commenting.

For Auqa 8K series resin, we recommend 30 minutes of post curing time. Thus we’d suggest you start with 30 minutes of post curing time for the mixture.

Hope this helps.

Best, Phrozen Team

>

Jamie

Phrozen, it would be awesome if you all are working on a purpose-made product like this that we could use right out of the bottle – hopefully one that would be equally suitable for small scales like 15mm or even 6mm as well as larger scales. 3D printing opens up a lot of new possibilities for me as a wargamer, but with everything there is to learn it can also quickly take over my hobby time. I look for solutions that are as ready out of the box as possible so that I can still have time to actually paint and play with the models I print.

———

Phrozen Technology replied:

Hi Jamie,

Thanks for your insightful comment! We’ve noticed the community’s interest in ready-to-use 3D printing solutions for miniatures. We’re actively researching and testing products that cater to various scales, making the process more convenient for hobbyists like you. Your feedback is invaluable as we work towards enhancing the 3D printing experience. Please stay tuned for updates!

Best, Phrozen Team

Phrozen, it would be awesome if you all are working on a purpose-made product like this that we could use right out of the bottle – hopefully one that would be equally suitable for small scales like 15mm or even 6mm as well as larger scales. 3D printing opens up a lot of new possibilities for me as a wargamer, but with everything there is to learn it can also quickly take over my hobby time. I look for solutions that are as ready out of the box as possible so that I can still have time to actually paint and play with the models I print.

———

Phrozen Technology replied:

Hi Jamie,

Thanks for your insightful comment! We’ve noticed the community’s interest in ready-to-use 3D printing solutions for miniatures. We’re actively researching and testing products that cater to various scales, making the process more convenient for hobbyists like you. Your feedback is invaluable as we work towards enhancing the 3D printing experience. Please stay tuned for updates!

Best, Phrozen Team

Timothy D.

How are the ratios measured? By volume or mass?

———

Phrozen Technology replied:

Hello Timothy,

Thank you for commenting. We’re measuring the ratios by using measuring cup when mixing it, so it should be by volume.

Hope this helps.

Best, Phrozen Team

>

How are the ratios measured? By volume or mass?

———

Phrozen Technology replied:

Hello Timothy,

Thank you for commenting. We’re measuring the ratios by using measuring cup when mixing it, so it should be by volume.

Hope this helps.

Best, Phrozen Team

>

Matthew Bonett

Hello Phrozen,

Interesting tutorial. I got a bottle of both aqua grey 8k and onyx impact plus and tried Luther’s 60/40 mix using the same printer settings. I got excellent results with the XP finder and RP tester, however when I tried printing pre-supported models I was not getting the same results. The raft prints and adheres to the plate but the supports adhere to the ACF film and am about to give up.

———

Phrozen Technology replied:

Hello Matthew,

Thank you for your comment. In this situation, we will suggest you to longer the exposure time for normal layer to see if the support can adhere to the raft.

Hope this helps.

Best, Phrozen Team.

>

Hello Phrozen,

Interesting tutorial. I got a bottle of both aqua grey 8k and onyx impact plus and tried Luther’s 60/40 mix using the same printer settings. I got excellent results with the XP finder and RP tester, however when I tried printing pre-supported models I was not getting the same results. The raft prints and adheres to the plate but the supports adhere to the ACF film and am about to give up.

———

Phrozen Technology replied:

Hello Matthew,

Thank you for your comment. In this situation, we will suggest you to longer the exposure time for normal layer to see if the support can adhere to the raft.

Hope this helps.

Best, Phrozen Team.

>

Milos

Hello Phrozen, can the resin-mixture stay in the bottle for some time?

When the right ratio and settings are stored as a profile, it would be great to just use the already prepared „cocktail“ from the bottle…

———

Phrozen Technology replied:

Hello Milos,

Thank you for your comment. Although mixing resin has been popular among the members in our community for quite some time, and experience shows that the well-liked Aqua Gray 8k plus Onyx Impact Plus formula is pretty stable, we will still suggest our users to mix just amount of resin they are going to print, and leave those two bottles of resin being separated for the rest of time.

The chemical reaction when mixing up those two ingredients is still unknown, we cannot be sure about would those which have already been mixed up can stay the quality as its initial state after times of standing. It is fun and challenging when making this kind of “homebrew” or “cocktail” style of resin and see what will happen, but since its ingredient is no longer the same as the one that comes out from the factory, we cannot guarantee its quality thus cannot recommend you to mix them up and just leave it there for a long time.

This question is both interesting and important. Thank you again for asking and we wish you an amazing printing journey.

Best, Phrozen Team

Hello Phrozen, can the resin-mixture stay in the bottle for some time?

When the right ratio and settings are stored as a profile, it would be great to just use the already prepared „cocktail“ from the bottle…

———

Phrozen Technology replied:

Hello Milos,

Thank you for your comment. Although mixing resin has been popular among the members in our community for quite some time, and experience shows that the well-liked Aqua Gray 8k plus Onyx Impact Plus formula is pretty stable, we will still suggest our users to mix just amount of resin they are going to print, and leave those two bottles of resin being separated for the rest of time.

The chemical reaction when mixing up those two ingredients is still unknown, we cannot be sure about would those which have already been mixed up can stay the quality as its initial state after times of standing. It is fun and challenging when making this kind of “homebrew” or “cocktail” style of resin and see what will happen, but since its ingredient is no longer the same as the one that comes out from the factory, we cannot guarantee its quality thus cannot recommend you to mix them up and just leave it there for a long time.

This question is both interesting and important. Thank you again for asking and we wish you an amazing printing journey.

Best, Phrozen Team

Jorge

What’s are the names of the cleric minatures?

———

Phrozen Technology replied:

Hello Jorge, thank you for asking. Those models printed out by Maria are from Loot Studios and Archvillain Games. For the specific model’s name, we suggest you to contact with the designers to get a correct answer. Best, Phrozen.

What’s are the names of the cleric minatures?

———

Phrozen Technology replied:

Hello Jorge, thank you for asking. Those models printed out by Maria are from Loot Studios and Archvillain Games. For the specific model’s name, we suggest you to contact with the designers to get a correct answer. Best, Phrozen.