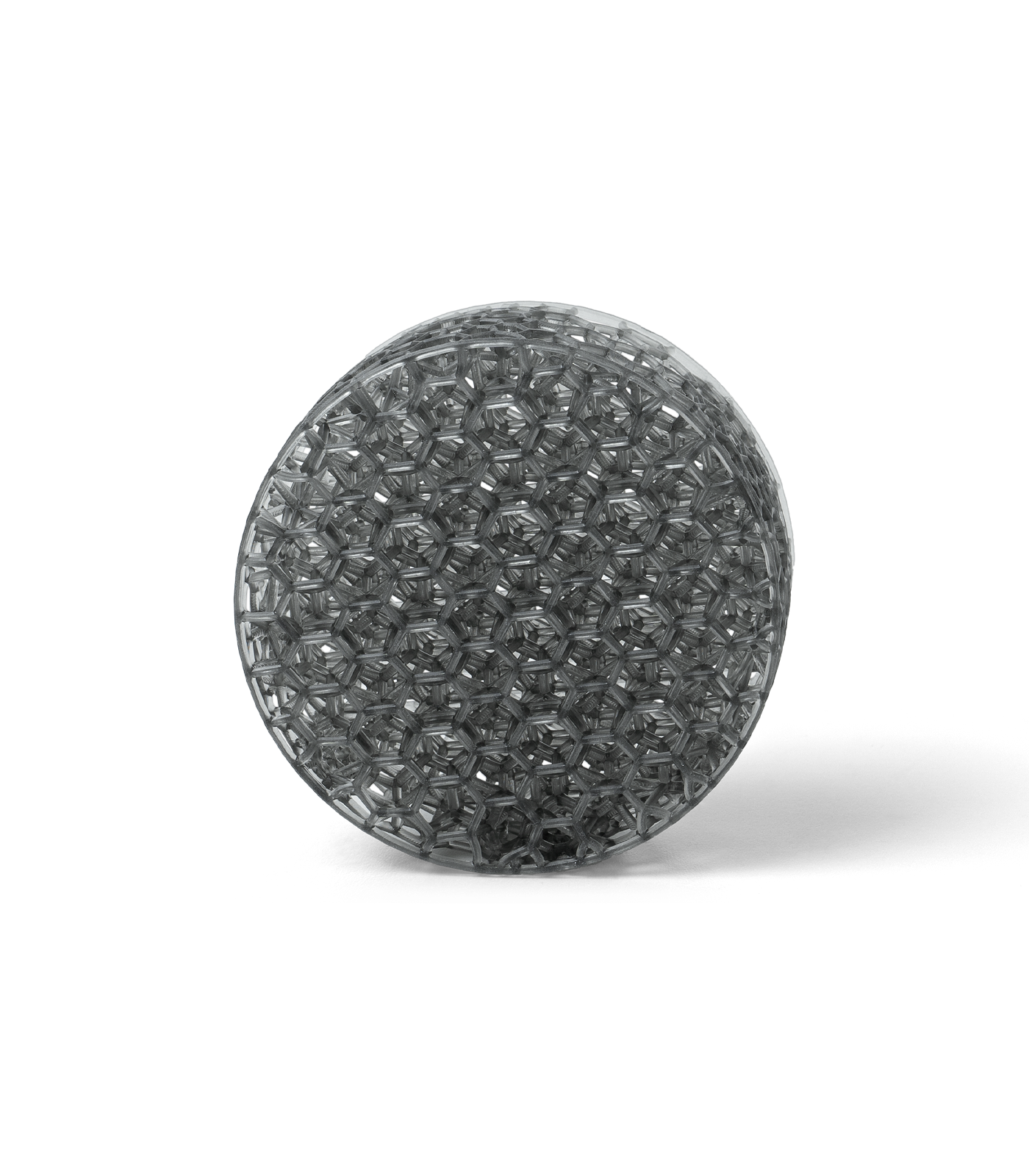

Create High-Performance Rubber-Like Models With Impressive Elastomer Properties

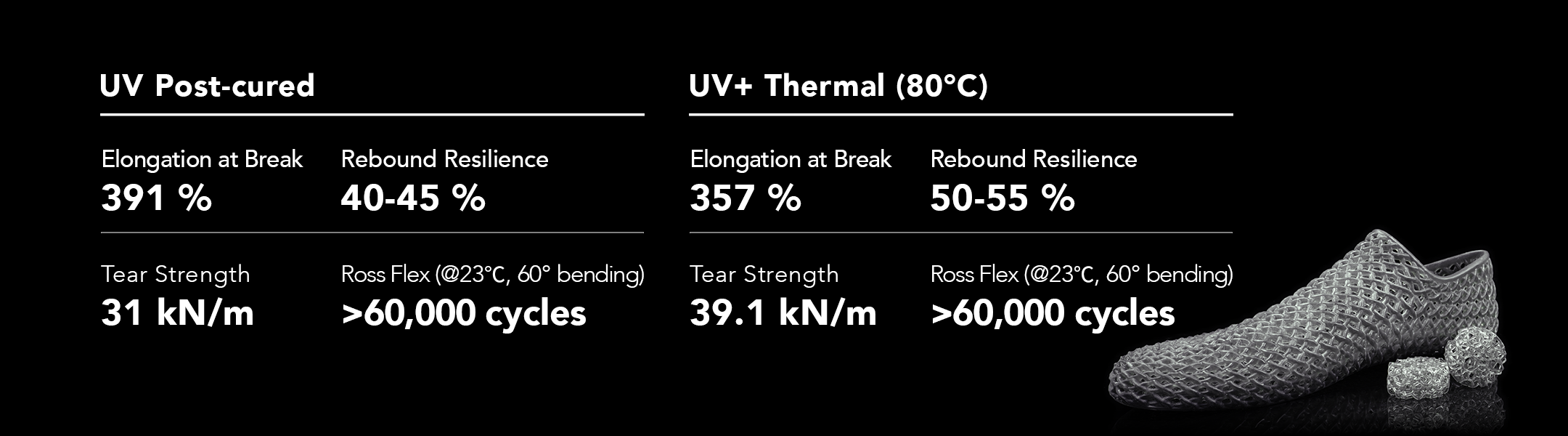

Models printed with EL400 exhibit superior reliability. Withstanding over 60,000 cycles at 23°C with a tear strength of 39.1kN/m*, it unlocks new opportunities for elastomer creations.

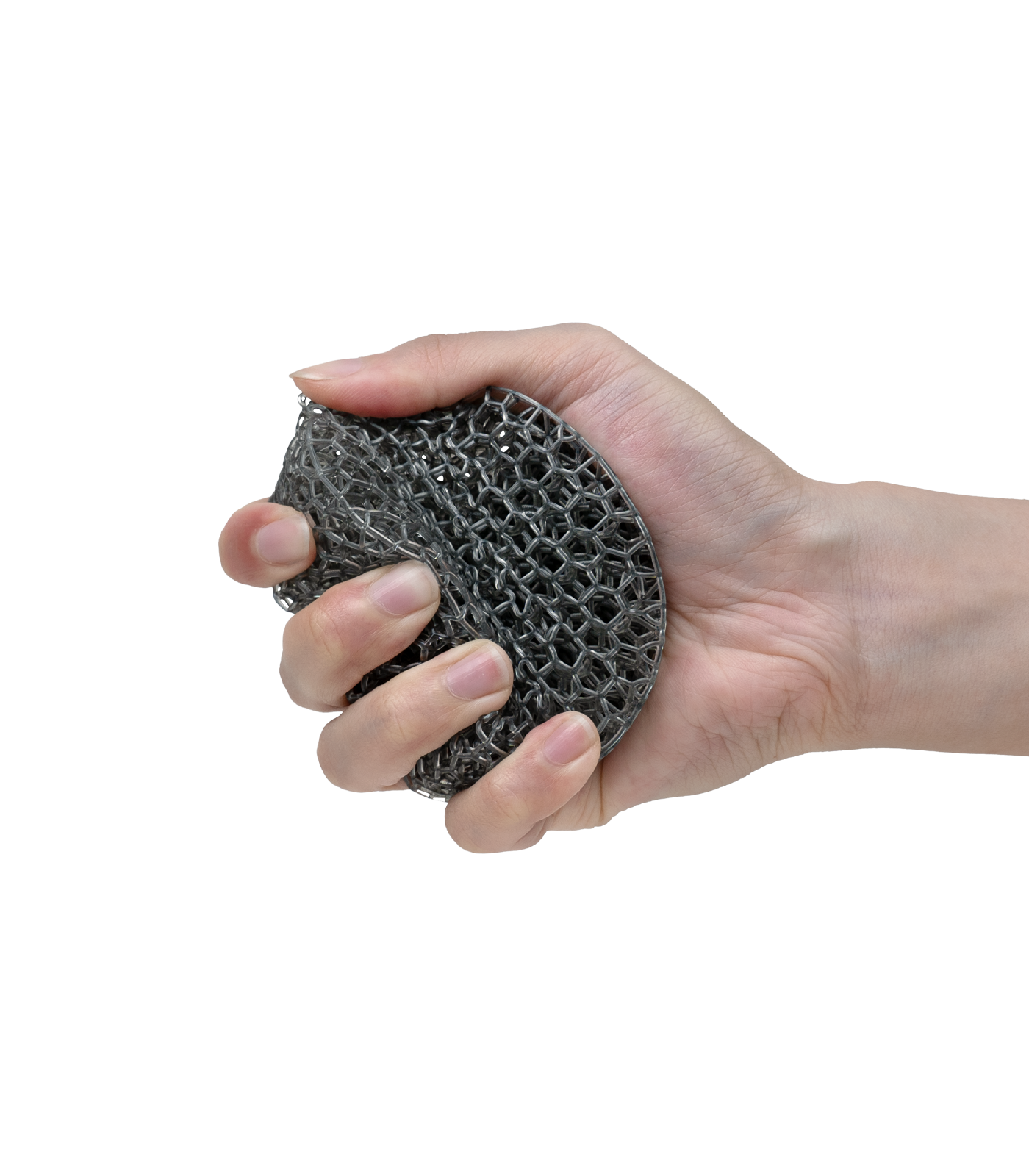

Ultra-High Elasticity

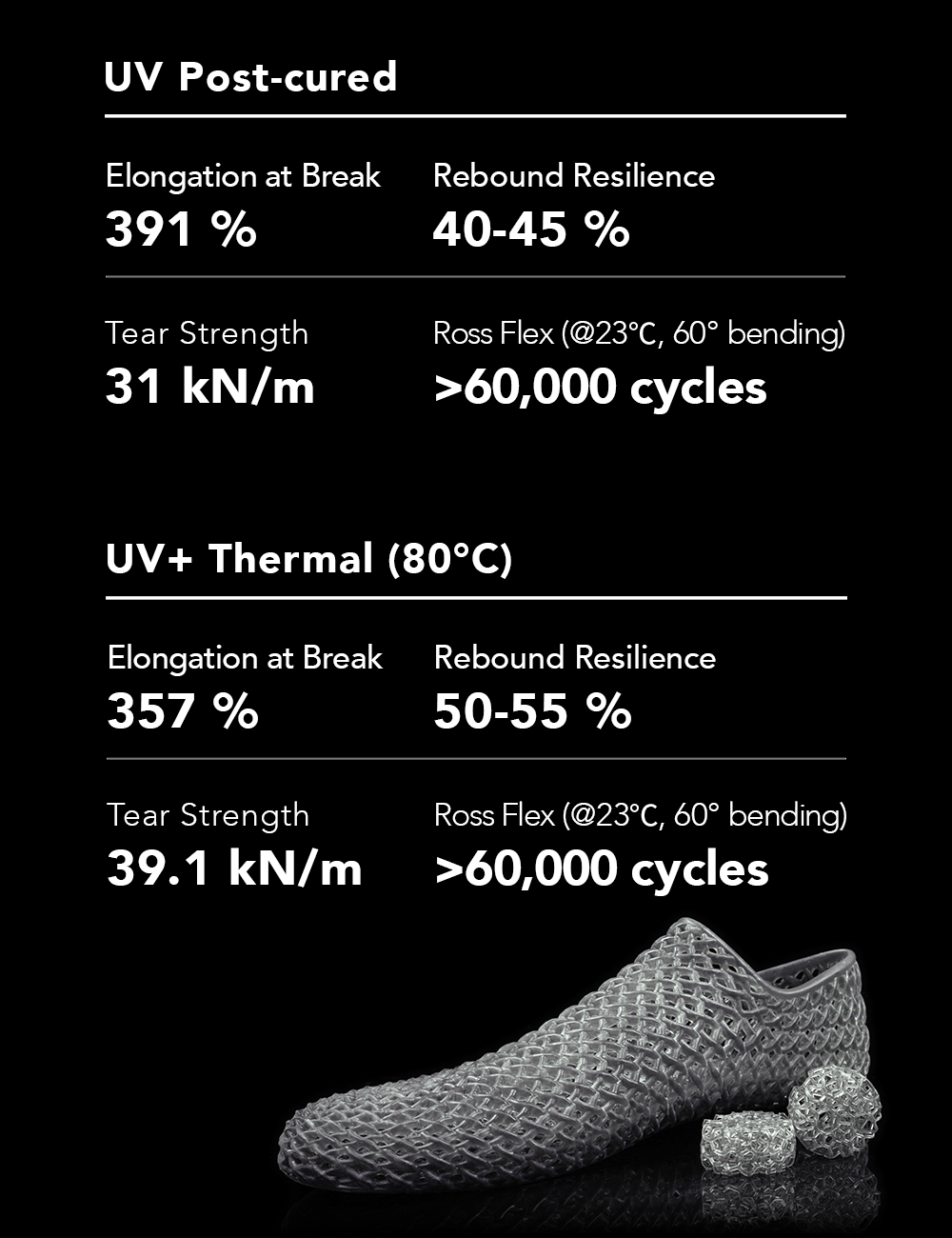

With an ultra-high 391% elongation at break, EL400 combines rubber-like elasticity and hardness, offering excellent flexibility and stability to realize your innovative designs.

Excellent Resilience and Reboundability

The EL400’s 50–55% Bayshore rebound rate* makes returning to its original shape after deformation seamless. Ideal for durable prototypes for long-term testing and repeated use.

Applications

Perfect for products with high-durability needs, such as bicycle seats and shoe cushions, it maintains optimum performance under repeated bending and tearing conditions, ensuring long-term use and reliability.

Robust Performance for Industry Standards

Developed as high-performance material with excellent elasticity and tear-resistant properties, models printed with EL400 are suitable even for industrial processes, resulting in an ideal material alternative to foam and TPU.

*The data provided is the performance results of a fully post-processed object. For complete post-processing methods, please refer to the user guide below.

Phrozen EL400 Elastomer Resin 3D Printing Resin

Price is calculated with GST and shipping included.

VISIT OUR STORE SITES TO MAKE A PURCHASE!

Printing Guideline

| Parameters | Recommended Settings |

|---|---|

| Layer thickness | 100 μm |

| Wall thickness | ≥ 1.5 mm |

| Lifting speed | 120 - 150 mm/min |

| Support thickness | 1.0 mm or ≥ 1.2 mm |

*Note:

1. To reduce deformation, printing directly on the building plate is recommended. If the model needs to be supported, please refer to point 2.

2. If the gaps between supports or within the model structure are too narrow, the resin may not cure properly and solidify in those areas.

3. When printing, reducing lifting and return speed while increasing the rest time is recommended for a successful print. Please adjust the return speed according to the model type.

4. Thermal post-curing can help improve the mechanical properties of the material, especially the tensile and tear strength, but may reduce ductility.

Post-Processing

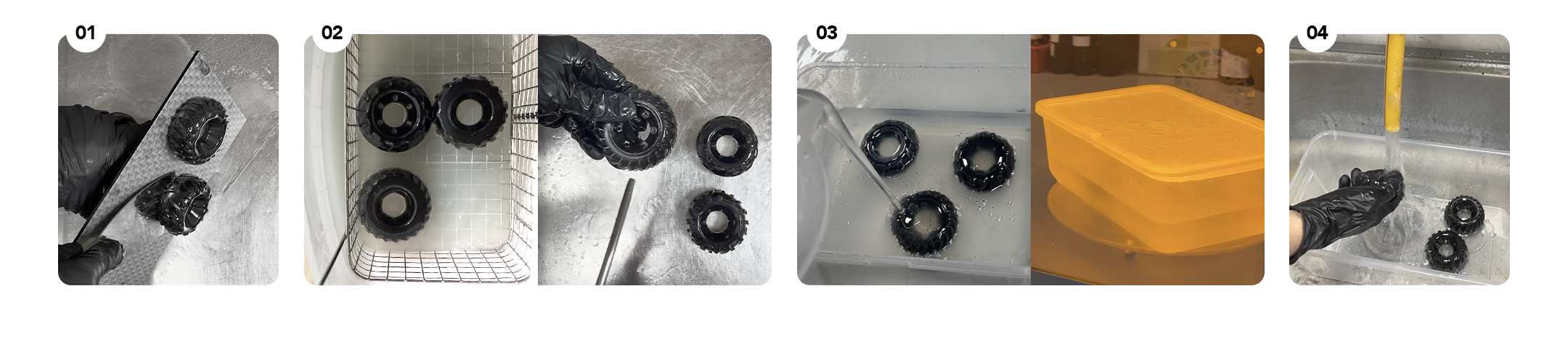

Cleaning and Drying

Wash in 95% ethanol using Phrozen Washing Station until its thoroughly cleaned (don’t soak for a prolonged period to avoid surface damage), then place in a cool, ventilated area away from sunlight until it dries, or use the drying function in the Phrozen Curing Station.

Post-Curing

Soak the models in glycerin and post-cure for about 60 minutes. Once completed, remove from glycerin immediately and clean up the models with water. Leave models in a cool, well-ventilated place for at least 60 minutes without exposure to light to dry.

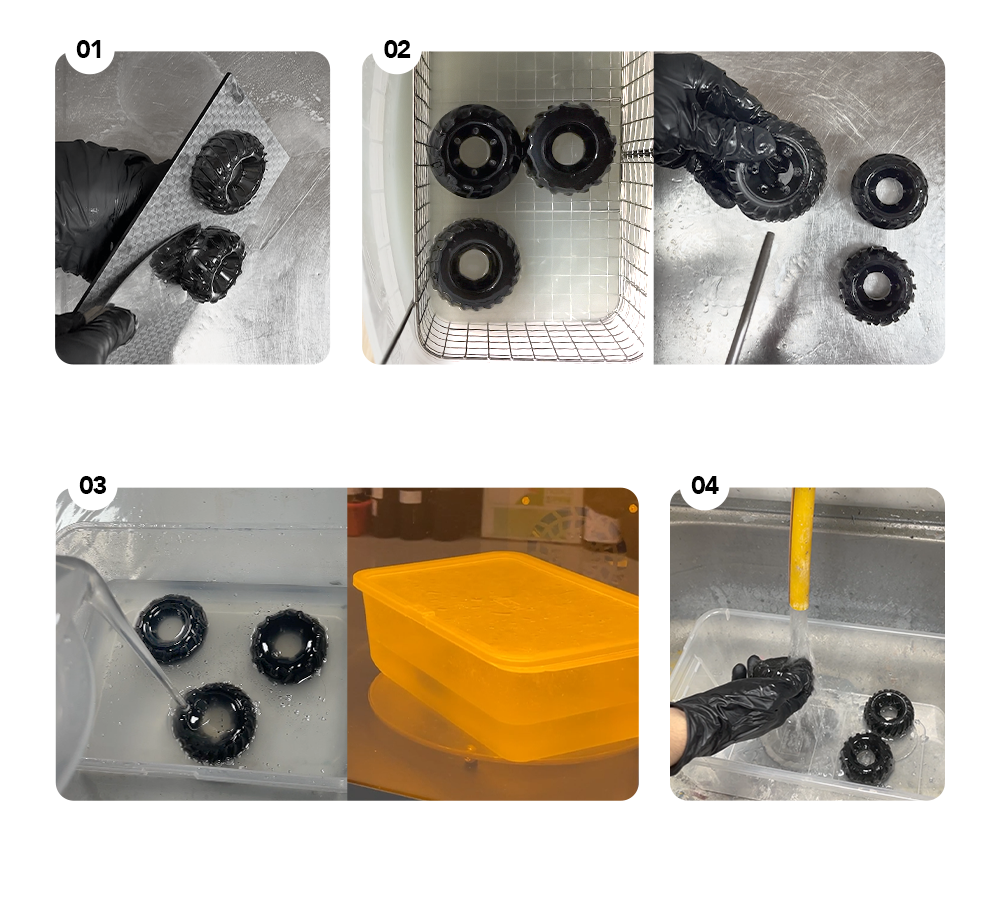

Final Cleaning

Rinse the model with clean water until it’s thoroughly cleaned and dry in a cool, ventilated area away from sunlight for 60 minutes or until the model dries completely. If required, an additional thermal post-cure at 80°C for 2 hours can be performed to enhance the mechanical properties of the models.

Description of Product Specifications TDS

Unless otherwise specified, all samples are the performance of printed parts. The information in this Technical Data Sheet (TDS), including all information and product recommendations, is based on our current knowledge and experience. Changes to descriptions, images, photographs, data, proportions, weights, etc., might occur without notice and do not constitute a contractual quality of the product. If required, please request Material Safety Data Sheets (MSDS) from your supplier or contact Phrozen Tech Co., Ltd.