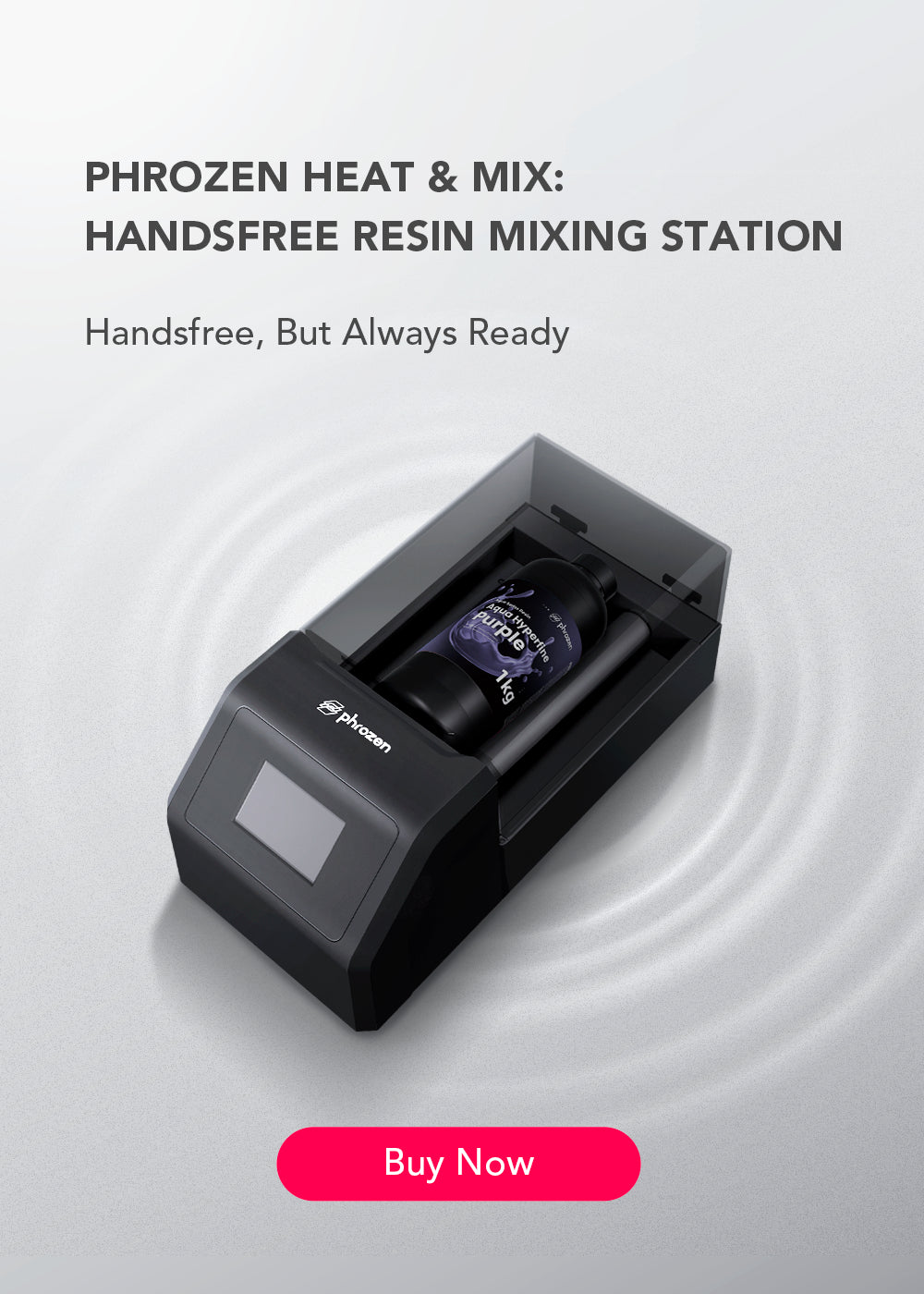

Consistently Flawless Prints Every Time

While manual shaking might work for some resins, automated mixing will ensure higher consistency and better mechanical properties, especially for highly viscous and high-composite resins.

Heat & Mix thoroughly blends and preheats your resin, preventing uneven composite and color inconsistencies ensuring smooth, flawless prints every time.

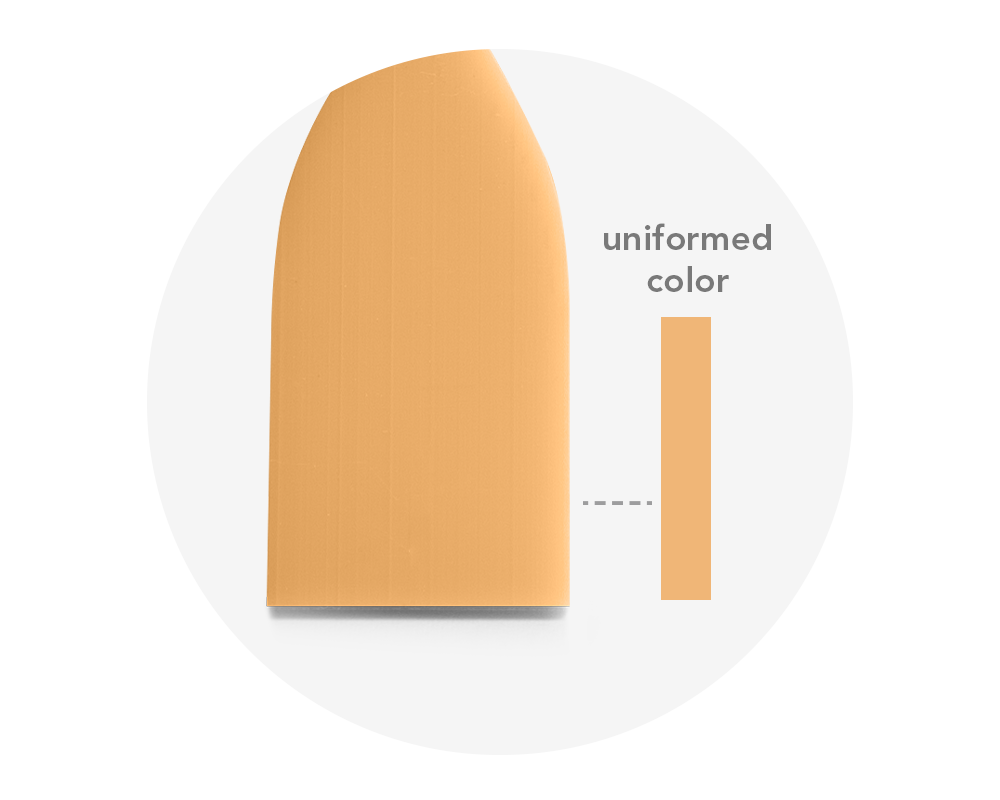

Before Heat & Mix

X Inconsistent color surface

X Unevenly mixed composite

X Weaker mechanical properties

After Heat & Mix

✔ Perfect aesthetic

✔ Evenly mixed resin & composite

✔ Stronger mechanical properties

✔ Increased success rate

Multidirectional Mixing for Thorough Homogenity

Heat & Mix uses multidirectional rolling and tilting to quickly and evenly disperse composites throughout the entire bottle*, ensuring every part is perfectly blended for optimum performance.

Flawless Prints Even in the Cold

Weatherproof your print with Heat & Mix! Say bye-bye to failed prints caused by cold resin. Preheat your resin to the optimum temperature, whether it rains or snows.

Compatible With Most Resins

Designed to fit most 500/1000 g round or square bottles (up to ⌀95x225mm), Heat & Mix seamlessly integrates into your workflow, whether you’re tackling hobby projects or professional 3D printing tasks.

Different Modes for Every Need

Whether you’re a hobbyist printing for yourself or managing a 3D printing farm, Heat & Mix has modes that will suit your needs.

Quick Shake (5 Mins)

Use Quick Shake for casual pre-printing prep. Continuously mix your resin for 5 minutes without heating.

Heat & Shake

Are you working with more viscous resin with high composite filler? Use Heat & Shake for optimum mixing with max. temperature of 50°C.

Constant Shake (Up to 6 Hours)

Always have your resin ready for the next pour by keeping it on standby for up to 6 hours with Constant Shake.

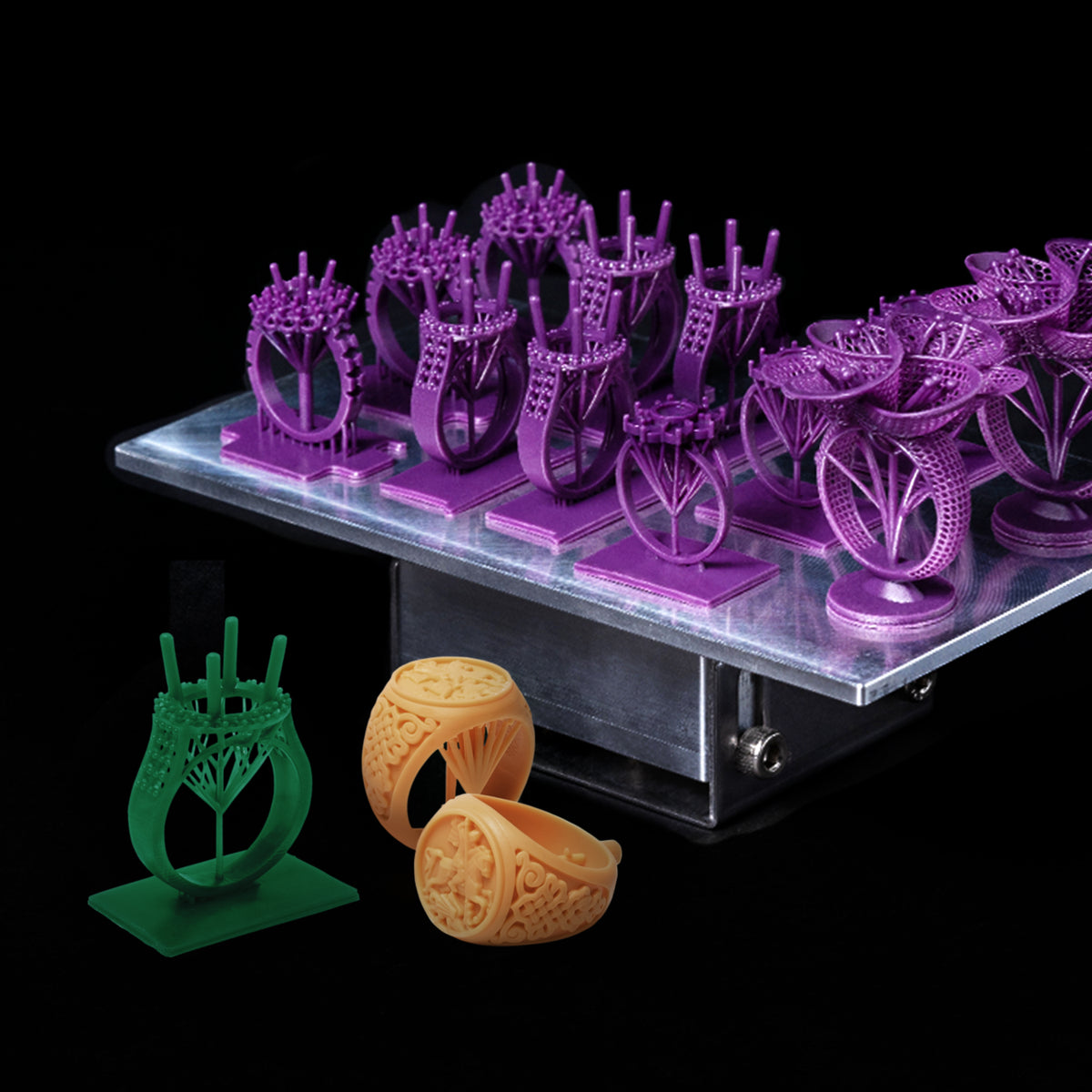

Engineered for Every Application

Resin homogeneity is crucial for jewelry and engineering professionals, ensuring optimal mechanical properties, success rate, and model performance. For print farms, Heat & Mix keeps your resin ready to go even while you focus on other tasks.

Engineering

Jewelry

Printing Farm

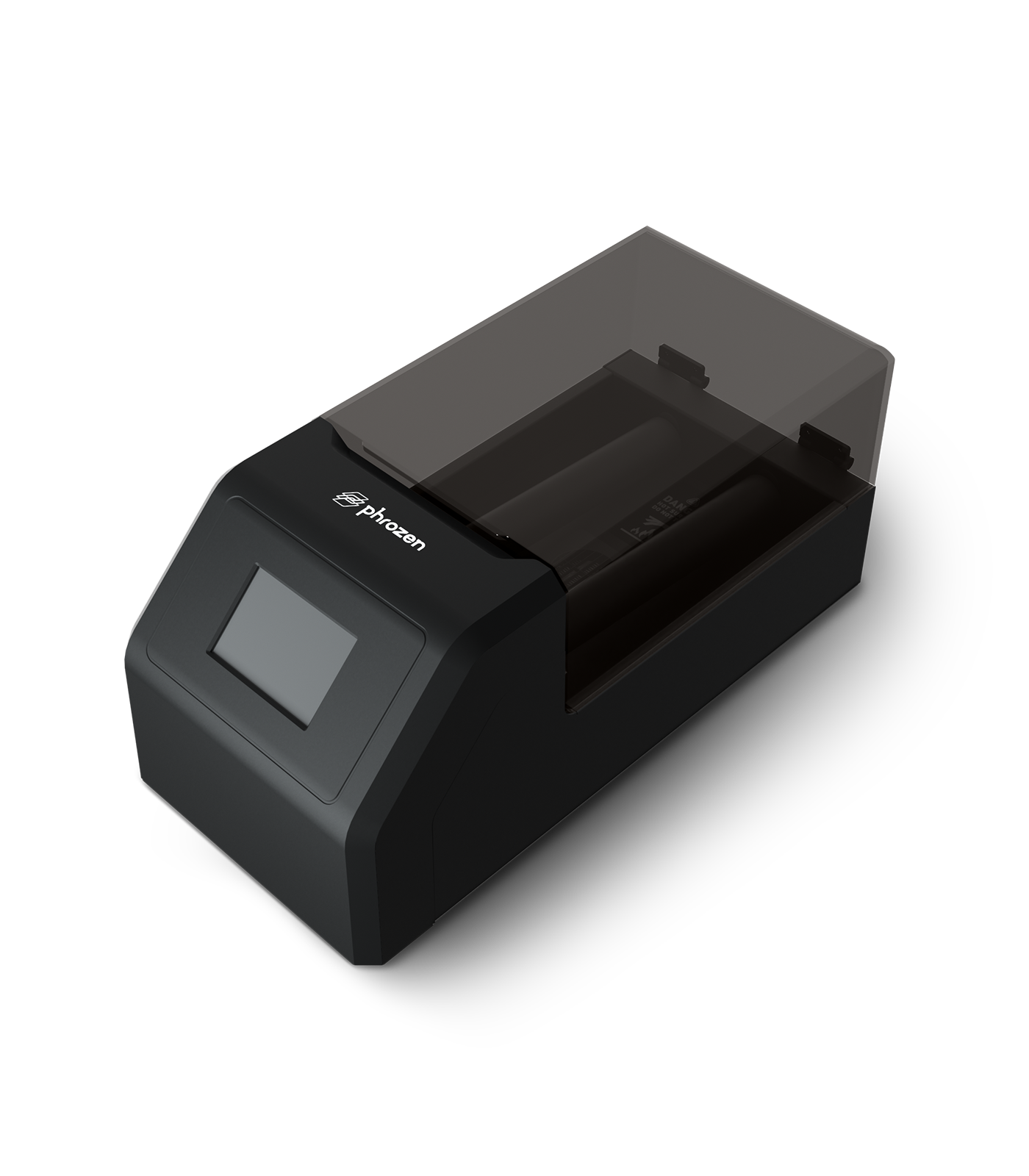

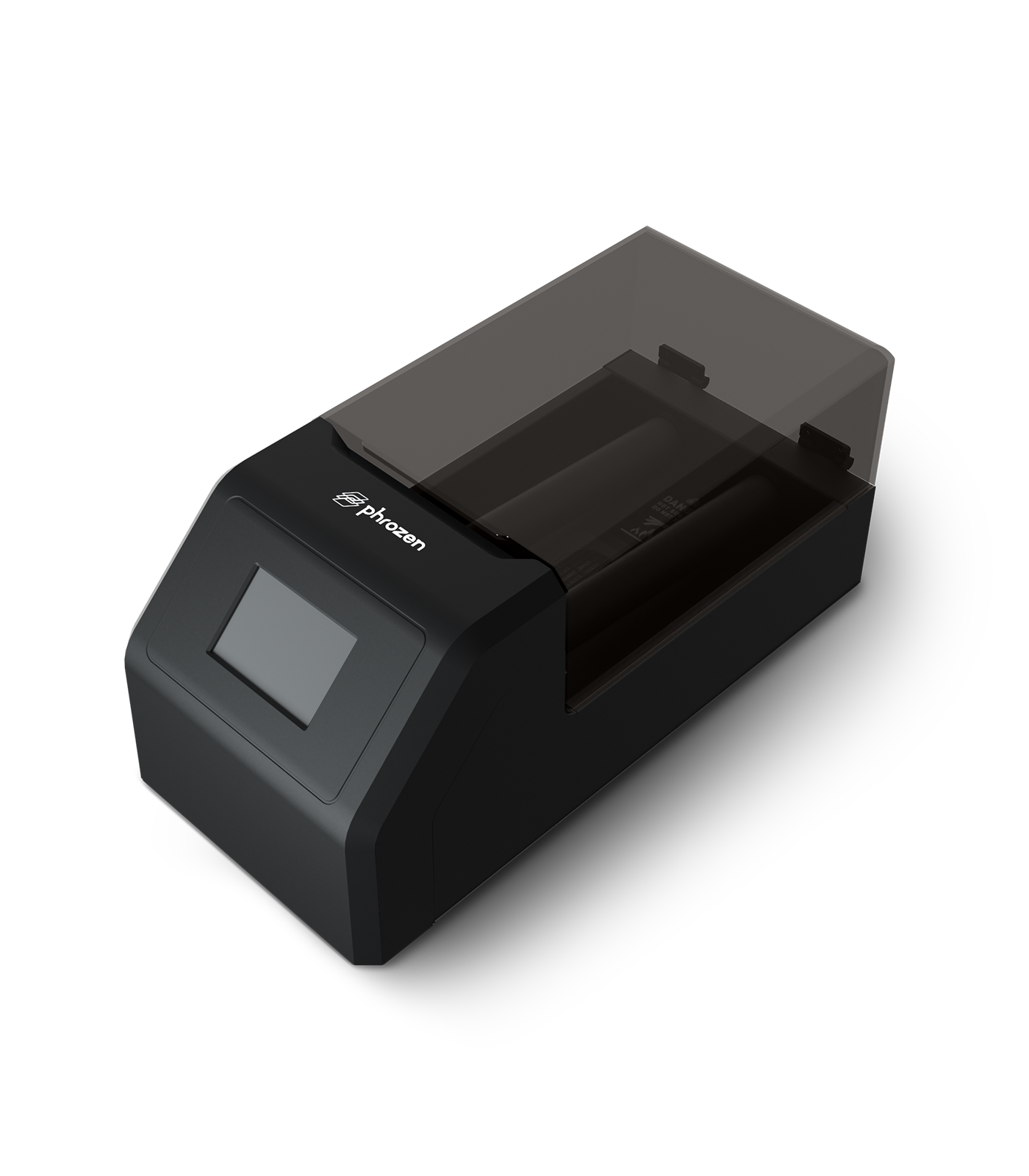

Specification

- Max. Heater Temp.: 50℃

- Dimensions: 41.6 x 20 x 19.2 cm

- Maximum Compatible Resin Bottle Size ( Ø x L ): 9.5 x 22.5 cm

- Weight: 4.5kg

- Power: 24V 5A

- Rated Power: 100W

What Mode Should You Use?

| Phrozen Resin | Third-Party Resin | |

|---|---|---|

| Quick Shake | Standard resin, Low viscosity engineering resin | Standard resin, Low viscosity engineering resin |

| Heat & Shake (±15 mins) |

|

Recommended for wax resin, ceramic resin, and other high-viscosity resin (>10000 mPas) |

Note:

*The transparent bottle is for demonstration purposes only. For actual use, if the original resin bottles don’t fit the machine, please use HDPE bottles of Ø9.5 x 22.5 cm size to ensure optimal safety and durability.