3D printing has taken the way we design, prototype, and manufacture products to the next level. With the advancements in technology, 3D printing has become more accessible and affordable for everyone, allowing businesses and individuals to turn their ideas into reality with ease. In recent years, we could have observed the immense popularity of this technique for prototyping. What are the benefits and best practices of resin 3D printing for prototyping? Keep reading to learn more!

What is resin 3D printing for prototyping?

Resin 3D printers are cutting-edge tools that rely on photopolymer resin as a printing material. The resin is cured using UV light to create a solid object layer by layer.

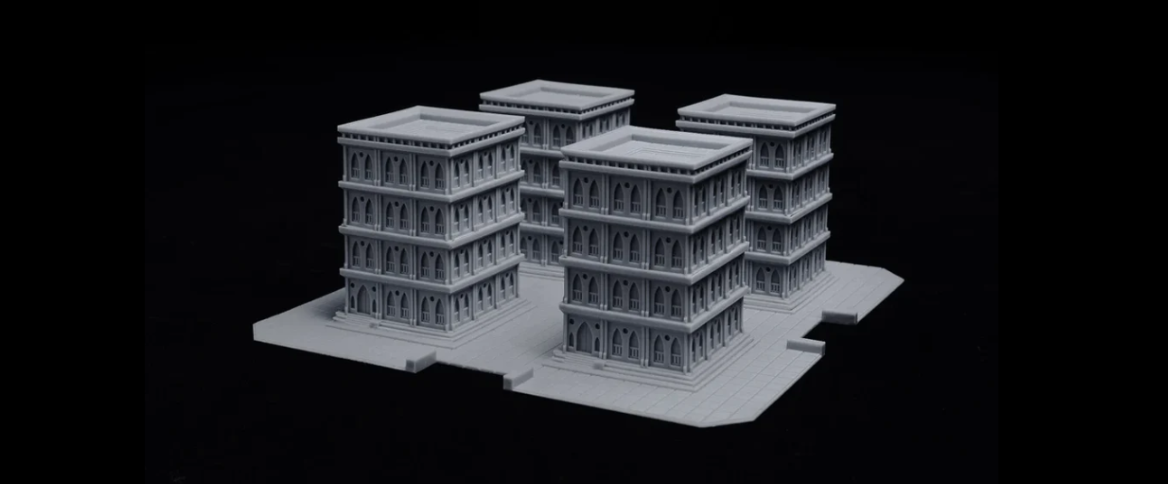

Resin 3D printing is known for its high level of detail and accuracy, making it a popular choice for creating prototypes.

Benefits of resin 3D printing for prototyping

There are many reasons why it’s worth using cutting-edge technology in everyday areas of life such as prototyping. The main benefits of 3D printing prototyping include:

- High level of detail and accuracy - resin 3D printing can produce prototypes with a high level of detail and accuracy, making it ideal for creating intricate designs and parts with small features. Phrozen Protowhite Rigid 3D Printing Resin is a great example of resin dedicated to this use case.

- Faster prototyping - this technology can produce prototypes quickly, allowing businesses to bring their products to market faster. This is because resin 3D printing is capable of producing multiple parts at once, reducing the time it takes to create a prototype.You can make this process even faster with our Speed Resin.

- Cost-effective - resin 3D printing is cost-effective compared to other traditional prototyping methods such as injection molding or CNC machining. It doesn’t require expensive tooling or molds which makes it an ideal choice for small-scale prototyping.

- Versatility - cutting-edge devices can print a wide range of materials, including flexible and rigid materials, which makes them suitable for creating a variety of prototypes.

Best practices for resin 3D printing for prototyping

Since you already know the benefits of 3D prototype printing, it’s time to talk about the best practices. How to ensure your prototypes are of high quality?

- There are different types of resins available for 3D printing, each with different properties and strengths. It’s important to choose the right resin for your application to ensure that your prototype meets your requirements.

- Resin 3D printing can produce highly detailed parts, but it requires optimizing your designs. Avoid unnecessary overhangs and design parts with appropriate wall thicknesses when printing.

- Parts of using resin 3D printers require taking care of your printer, replacing worn-out elements, and using proper post-processing with methods like thoroughly cleaning up any excess resin with compatible cleaning solution and curing it properly.

The takeaway

Resin 3D printing for prototyping offers numerous benefits, including high level of detail and accuracy, faster prototyping, cost-effectiveness, and versatility.

To achieve the best results, it’s important to choose the right resin, optimize your design, maintain your equipment properly, and post-process your printed parts. With these best practices in mind, resin 3D printing for prototyping can help businesses and individuals bring their ideas to life quickly and cost-effectively.