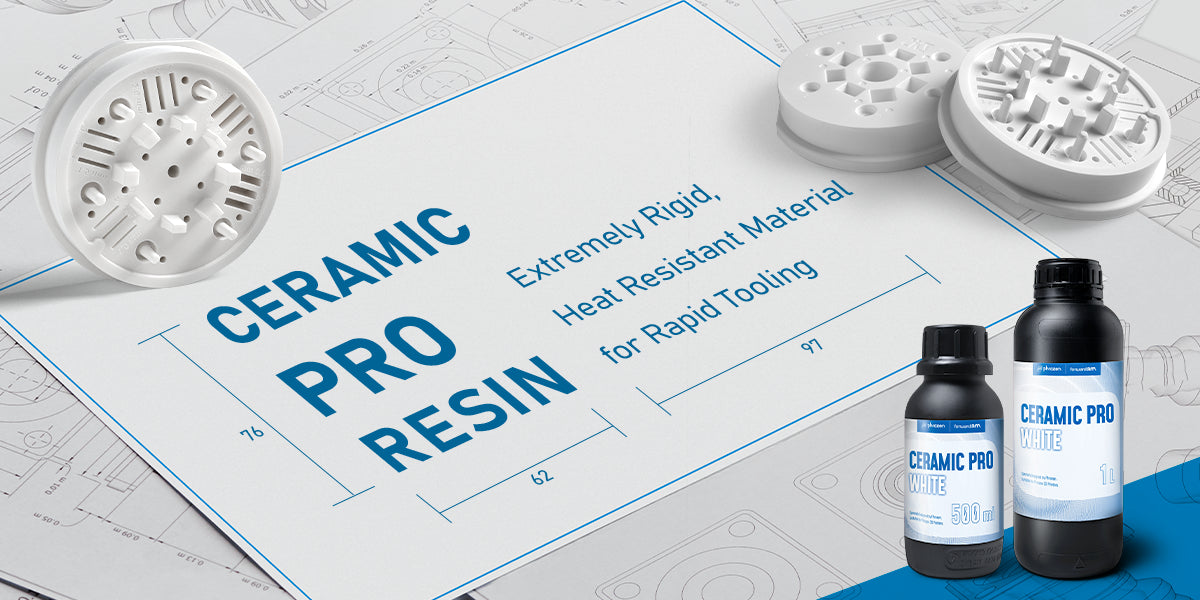

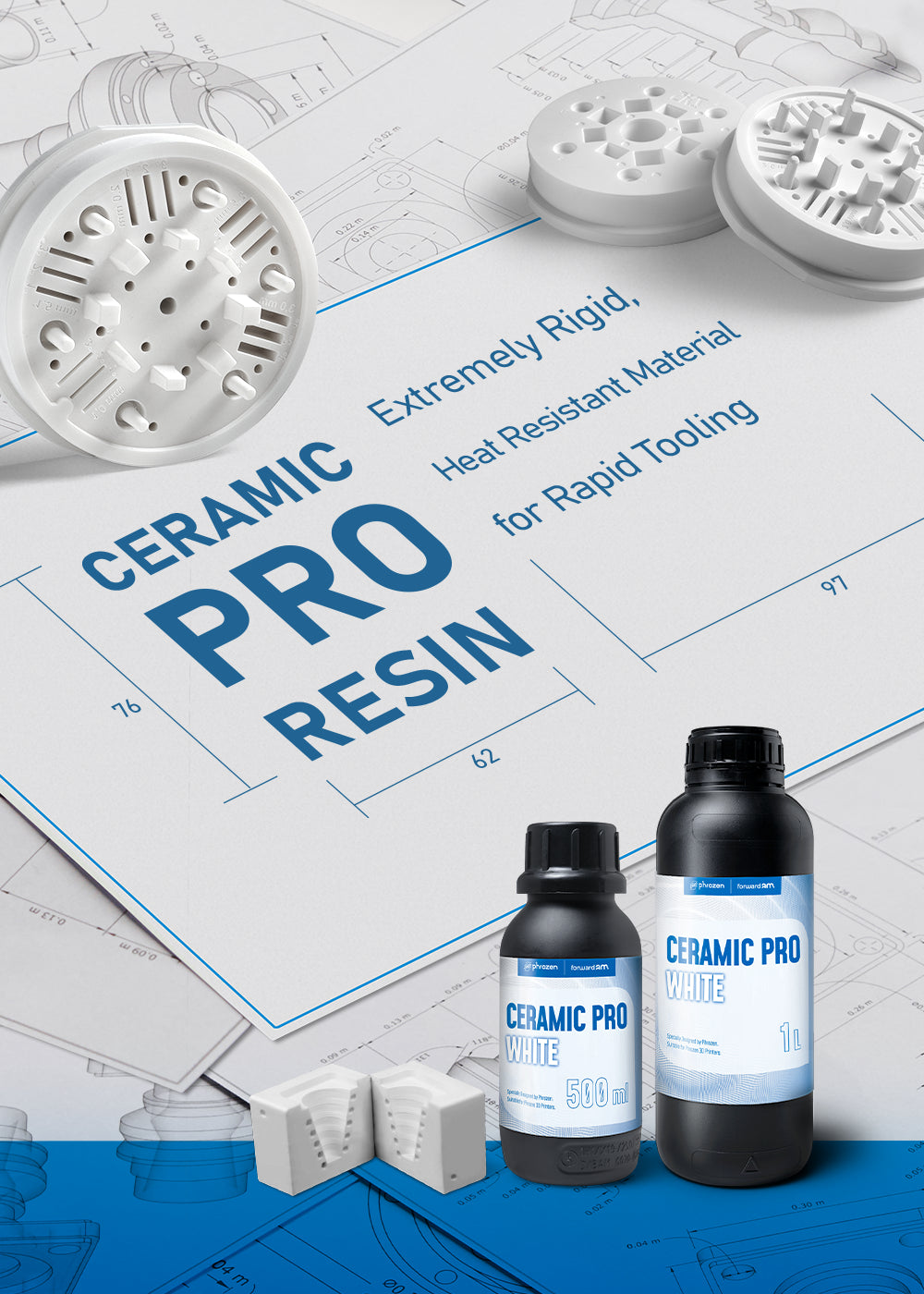

Incorporating 3D Printing Into Injection Molding Production

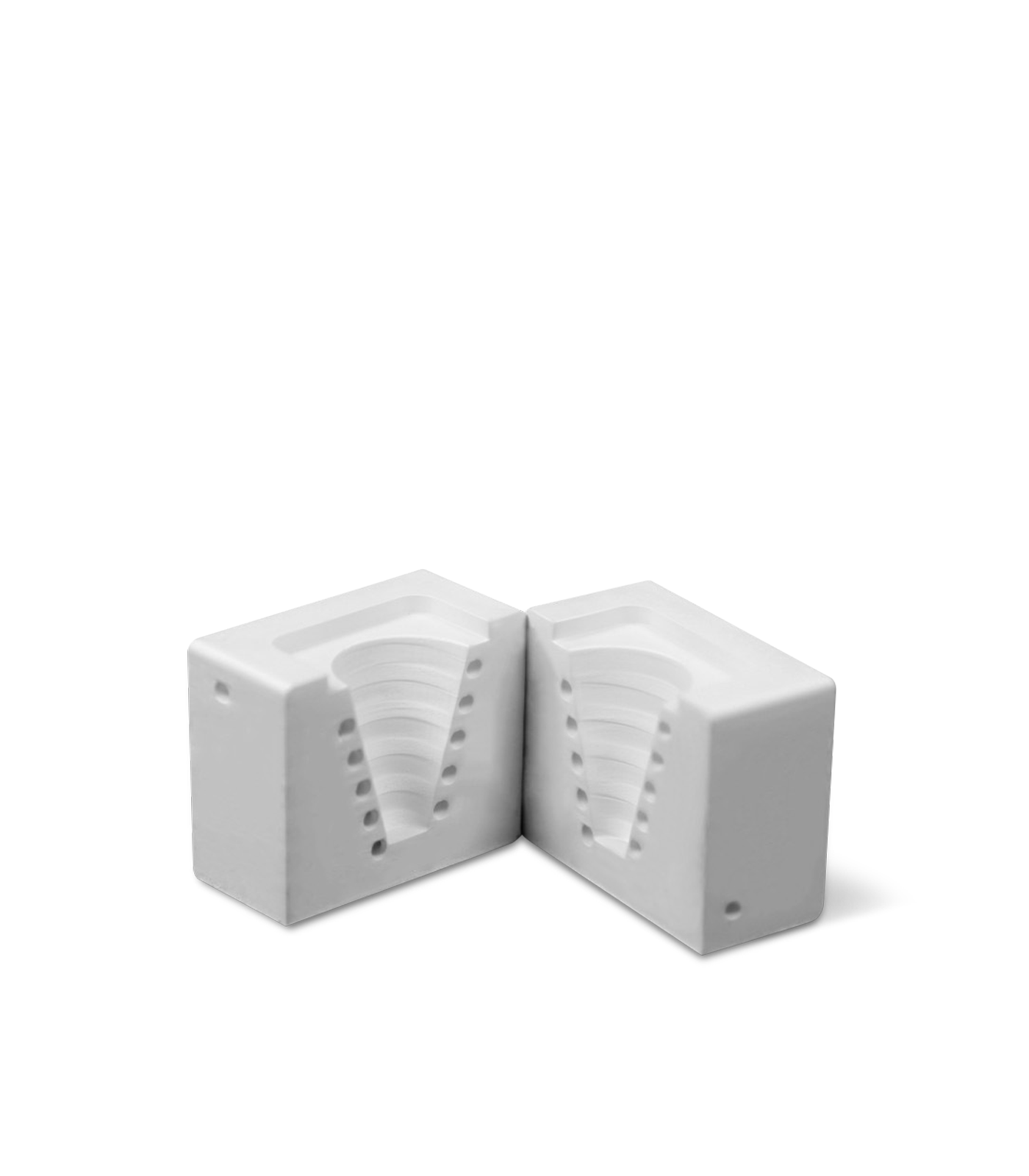

Traditional production methods for injection molding cores are highly expensive, with turnaround times of 4–5 weeks. So, we partnered with Forward AM to develop Ceramic Pro Resin as a more agile & reliable solution for injection molding core production. With just a fraction of the time and cost, it's highly cost-effective for small-batch production.

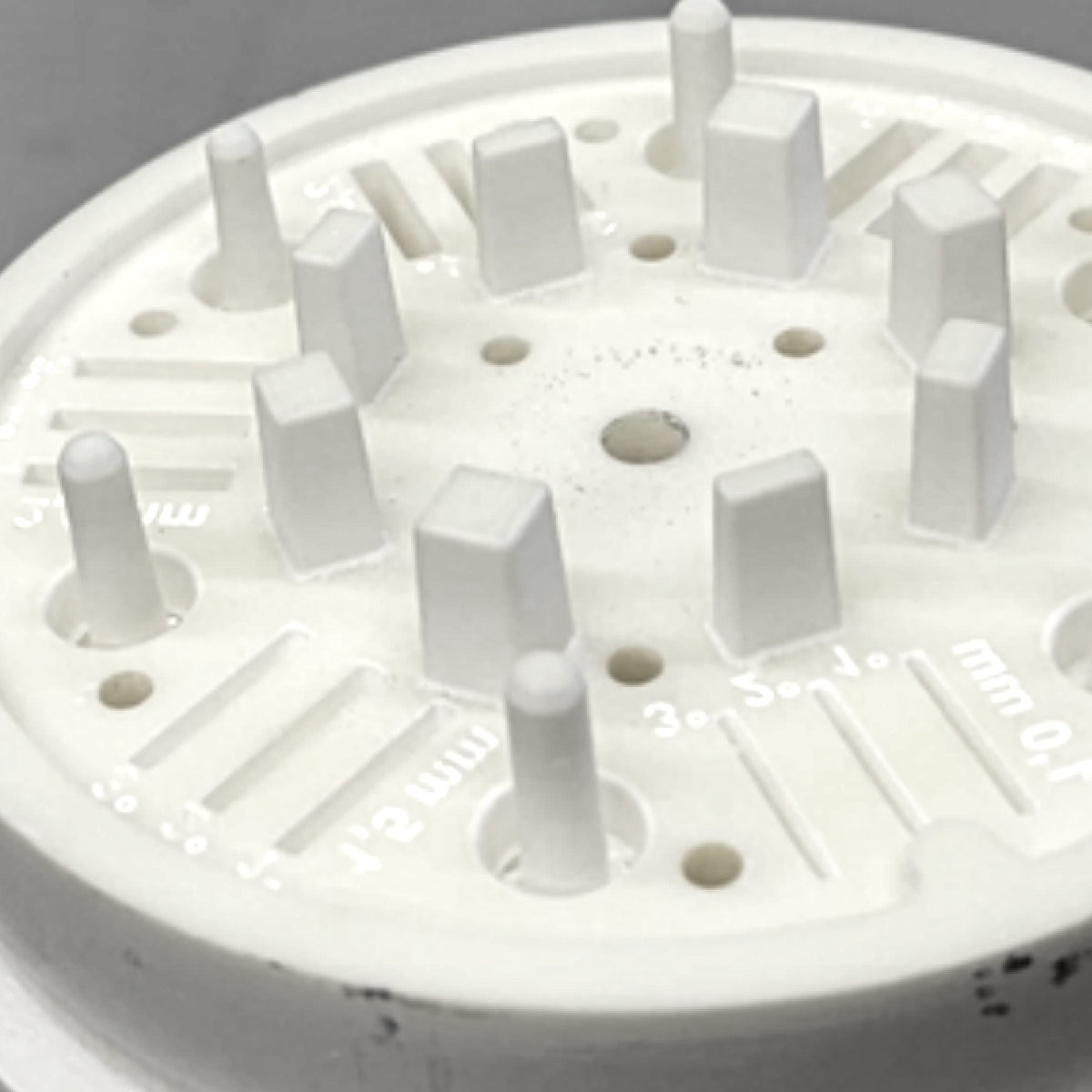

1. 3D print the mold.

2. Sand and polish the 3D printed mold.

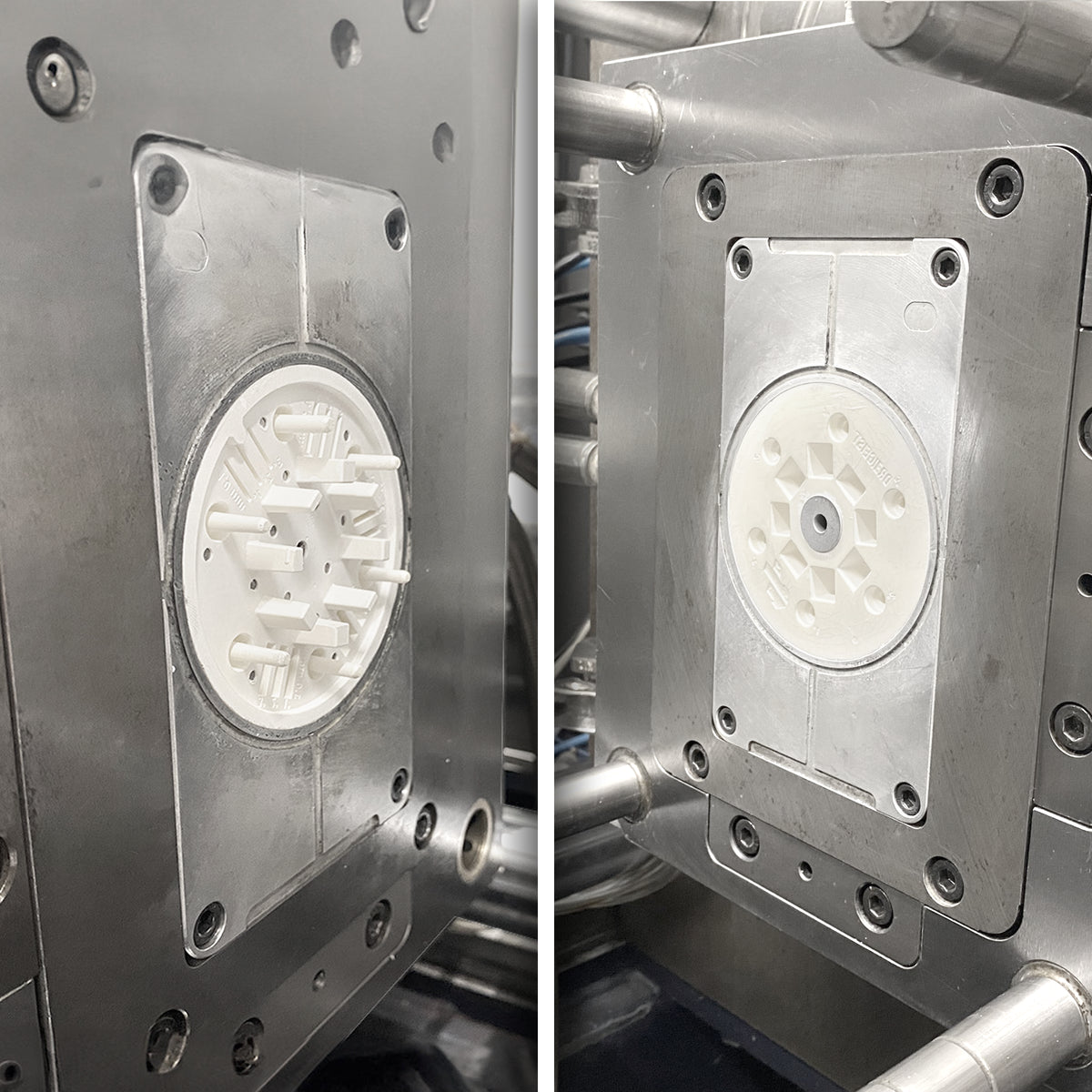

3. Install mold.

4. Start plastic parts production.

Ceramic Pro Benefits for Injection Molding Applications

Reliable Properties for Injection Molding Mold

With extreme stiffness and great heat & chemical resistance, Ceramic Pro Resin is easy to print and a great fit for injection molding mold production.

- 280°C heat resistant

- 10086 MPa flexural modulus

- 230 cps viscosity (@ 30°C)

- Over 70% ceramic content

Unlock Accessible, Efficient Manufacturing Options

Ceramic Pro Resin complements traditional injection molding manufacturing by offering a flexible, cost-effective alternative for small-batch and custom production, making high-quality mold manufacturing more accessible to a broader range of applications.

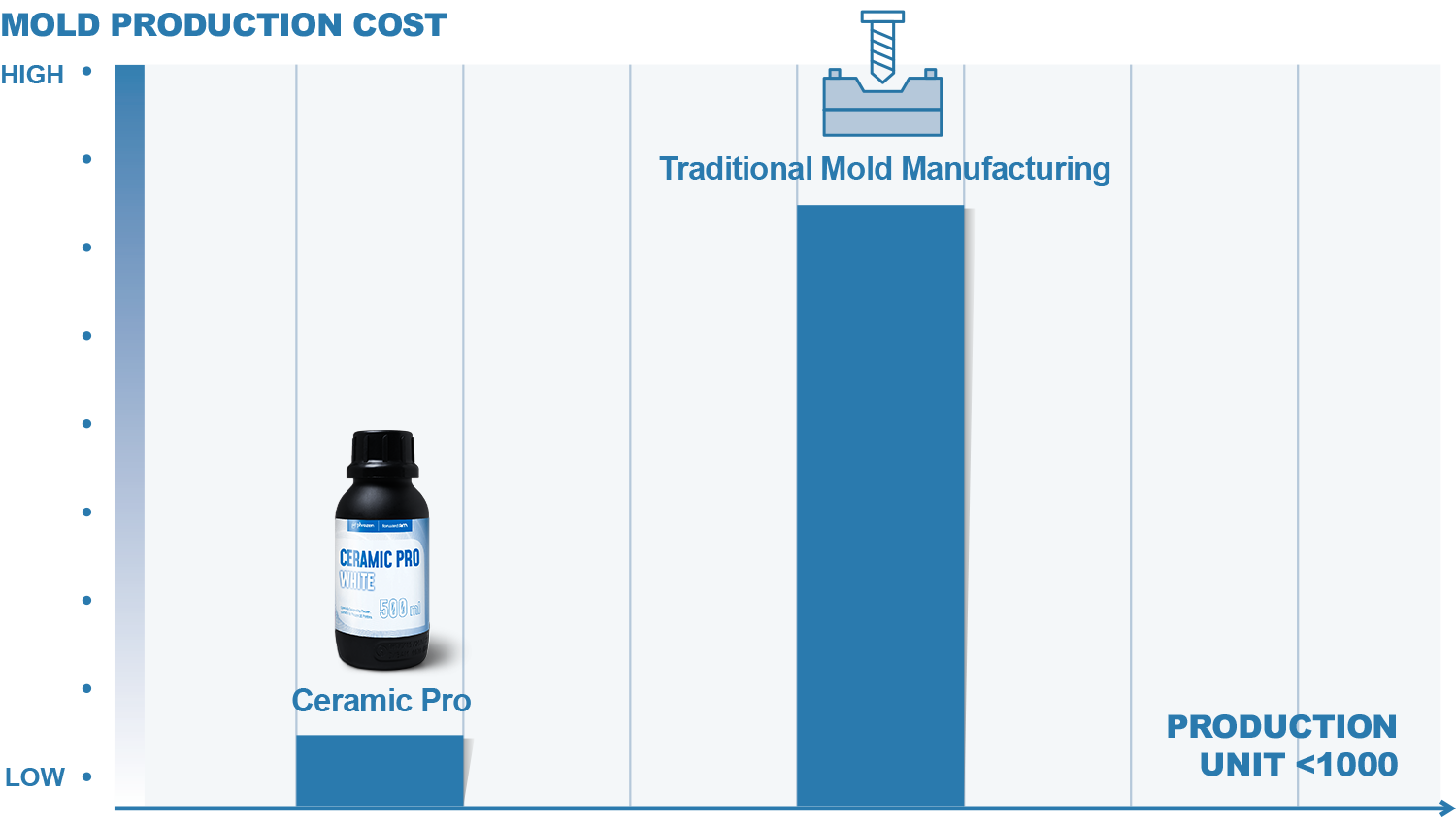

Saving Production Time and Cost by 80%

By eliminating high MOQ requirements, long lead times, and extensive tooling costs typically associated with manufacturing, Ceramic Pro Resin reduces mold production time from weeks to under a day while saving up to 80% of production costs.

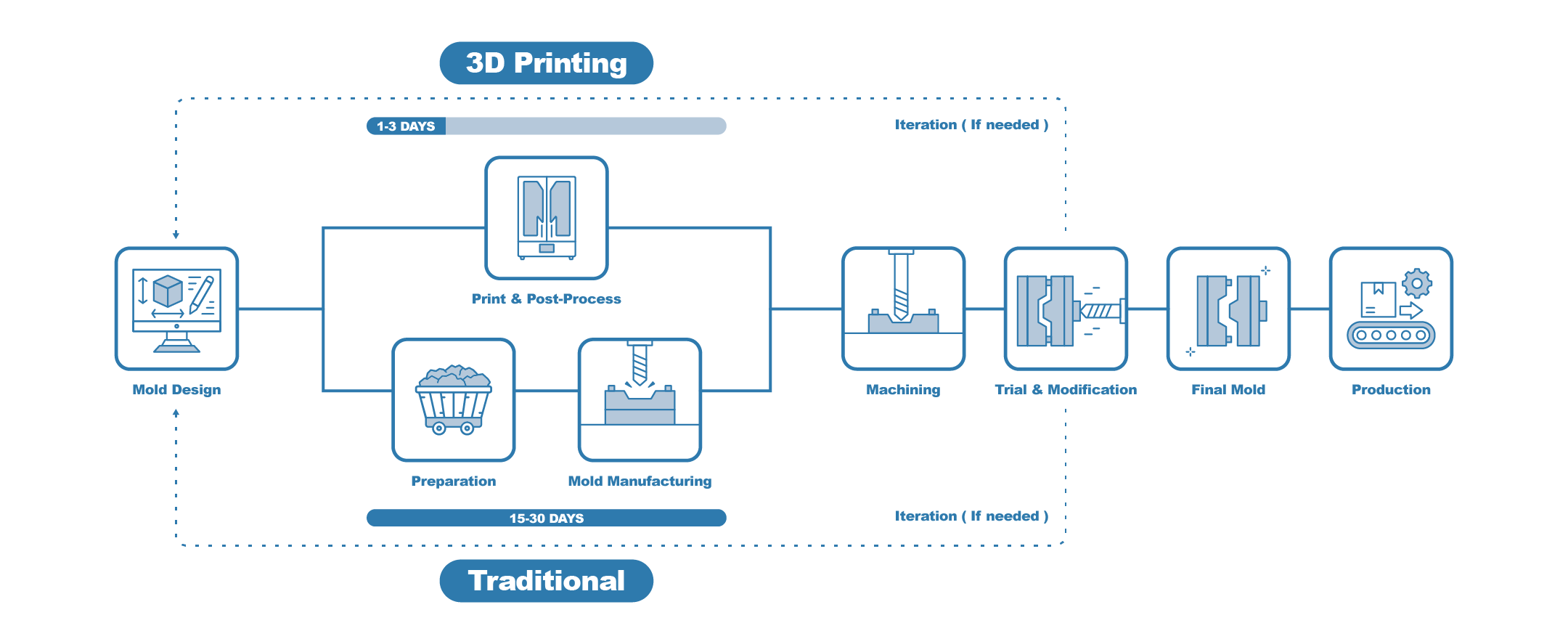

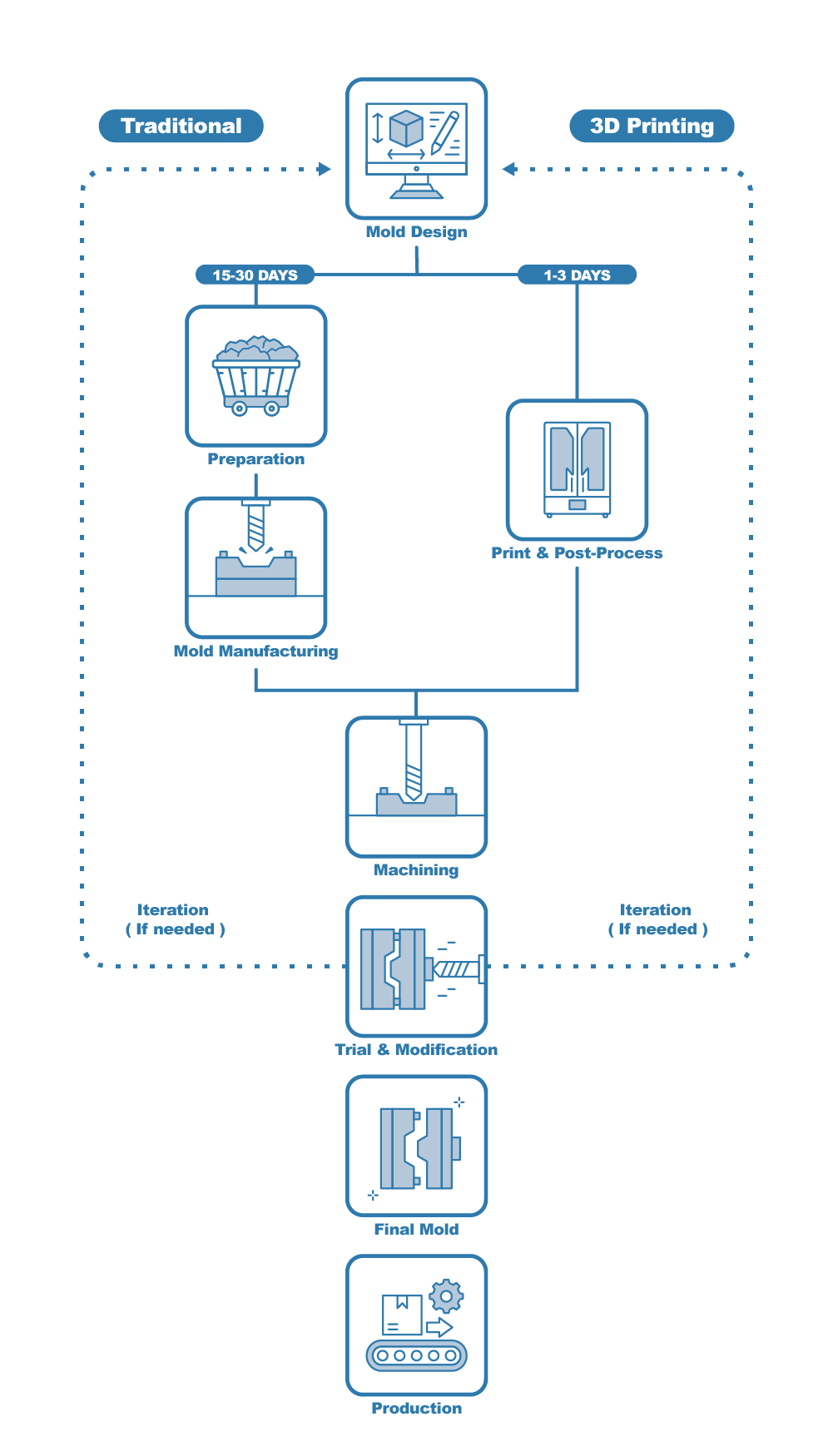

3D Printing vs Traditional Method

Small Batch Injection Molding Production

Learn How 3D Printed Mold Enhanced Productions

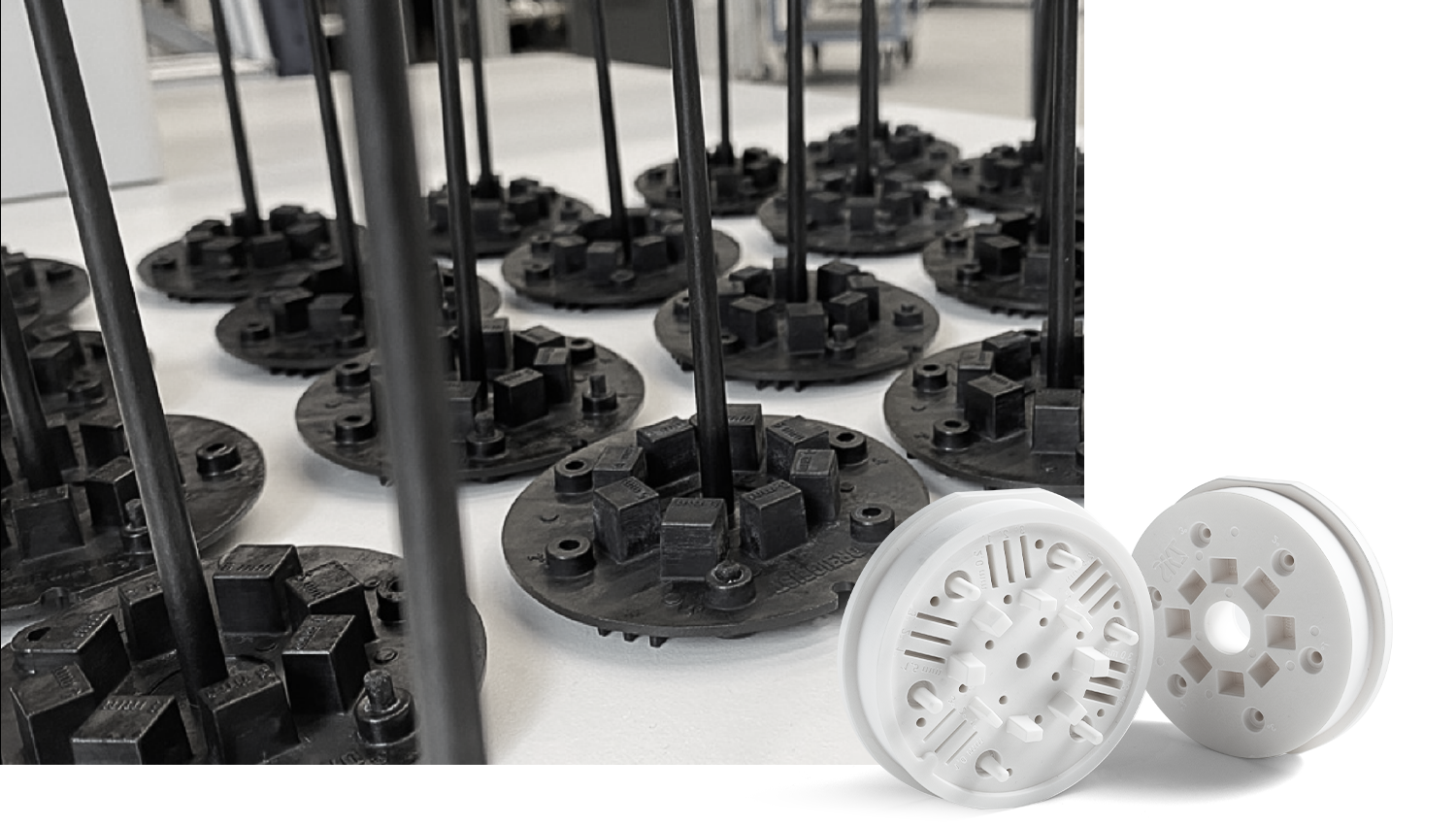

Overmolding

Ceramic Pro Resin is suitable for overmolding cable production, providing a fast, cost-effective solution to produce functional mold inserts with high precision and durability. It reduces production time to 3-4 days, minimizes costly mold iterations, and saves over €5,000 in overheads.

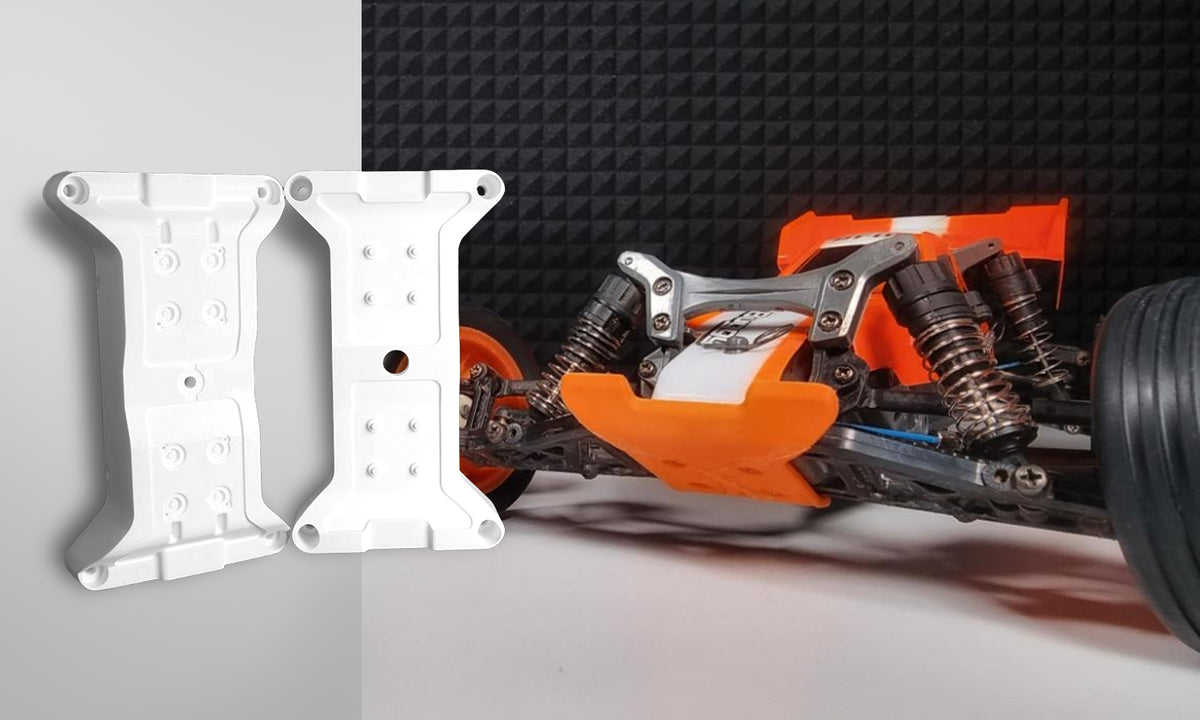

Injection Molding

While traditional milling costs up to €6,000 and takes 4–6 weeks, RC car molds with Ceramic Pro Resin cost just under €500 and are ready in about 9 hours. Its superior stiffness and high HDT offer a faster, cost-effective alternative to traditional tooling.

Image credit: SKZ – DREIGEIST – 3AM-Racing

Get the Best Out of Your Ceramic Pro Resin

Cleaning and Drying

- Remove any trapped resin from holes in the model.

- Wash in 99% IPA until it’s thoroughly cleaned for 30 – 60 seconds (don’t soak for more than 60 seconds to avoid surface damage).

- Dry the model with an air gun or use the drying function in Phrozen Curing Station for 10 – 30 mins.

*When printing flat on the building plate, remove the printed objects carefully to avoid deformation on the objects.

*Remember to clean the inner parts of hollowed objects thoroughly.

Post-Curing

Cure the models in a post-curing unit for 120 minutes (60 mins/per side) for best results.

Thermal Curing

Perform thermal post-curing to enhance the mechanical properties of the models by baking them in a precise temperature-controlled oven (±2°C tolerance) by following the settings below:

| Time Settings | Temperature Settings | |

|---|---|---|

| Ramp up phase | 2 hours | 30°C — 150°C |

| Holding phase | 3 hours | 150°C |

| Ramp down phase | 2 hours | 150°C — 30°C |