Z-axis calibration is essential for every 3D printer. Run this test to make sure that the building plate is leveled to the LCD screen. This is to ensure that models and prints will adhere to the building plate.

We will guide you through the steps of calibrating your Sonic Mini 4K LCD 3D printer by using a piece of A4 paper:

Step 1: Settings

On the touch panel, click TOOLS, then click Z CALIB on your touch panel to begin the calibration process.

Before clicking NEXT, please complete steps 2 - 4.

Step 2: Remove the Resin Vat

Remove the resin vat and make sure to remove any objects present on the machine's platform.

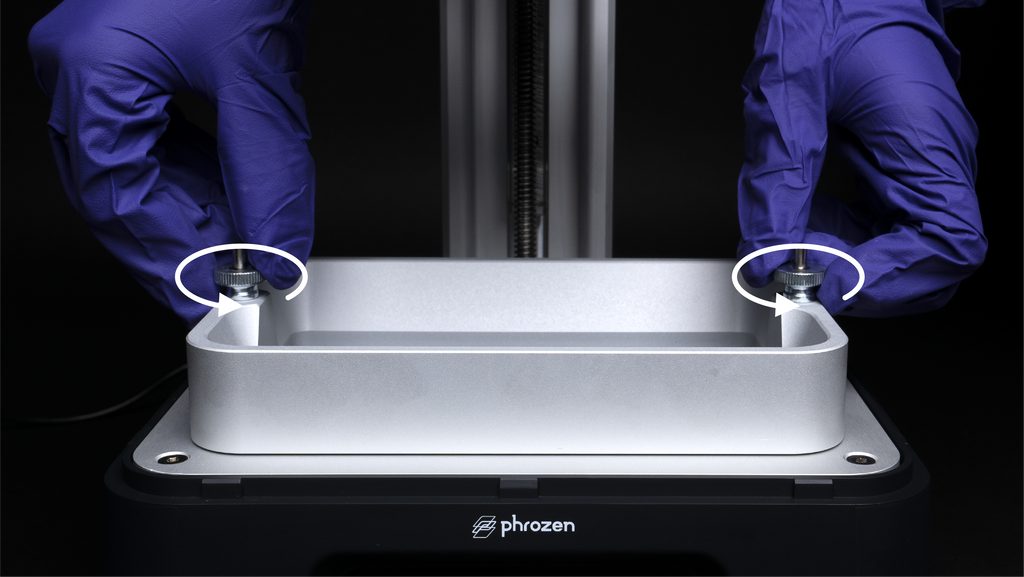

Step 3: Install the Building Plate

Attach the building plate knob to the printer and align it with the pins. Screw and tighten the building plate.

*Note: Please ensure that the building plate does not shift during tightening.

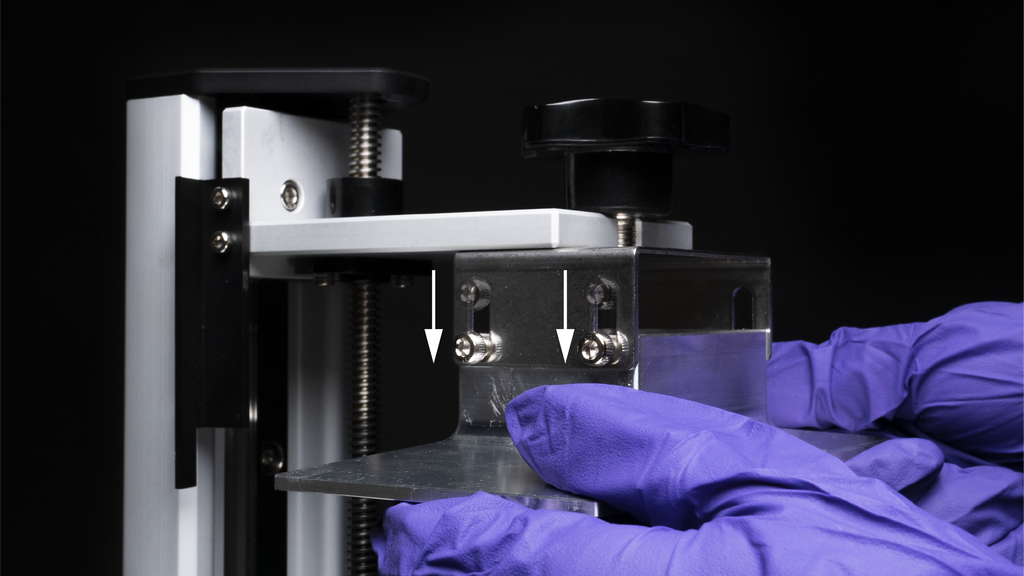

Step 4: Loosen the Screws

Use the Allen wrench included in the toolbox to loosen all 4 screws on the sides of the building plate in a counterclockwise direction. After loosening it, double-check to see if the plate is loose and movable.

Step 5: Pull the Building Plate down

Pull the building plate in a downward motion until the screws on the building plate have been pulled down completely.

Step 6: Place a piece of paper on the LCD

Prepare a piece of A4 paper (roughly 0.07-0.10 mm) and lay it flat on the LCD screen. This piece of paper will be used for leveling the building plate. Click NEXT and wait for 1-2 minutes as the building plate extends to the LCD screen.

Step 7: Apply Pressure on the Building Plate

Once the building plate has touched down, apply pressure and press down firmly on the sides of the building plate. Pull on the piece of paper to make sure the building plate is laying tight against it.

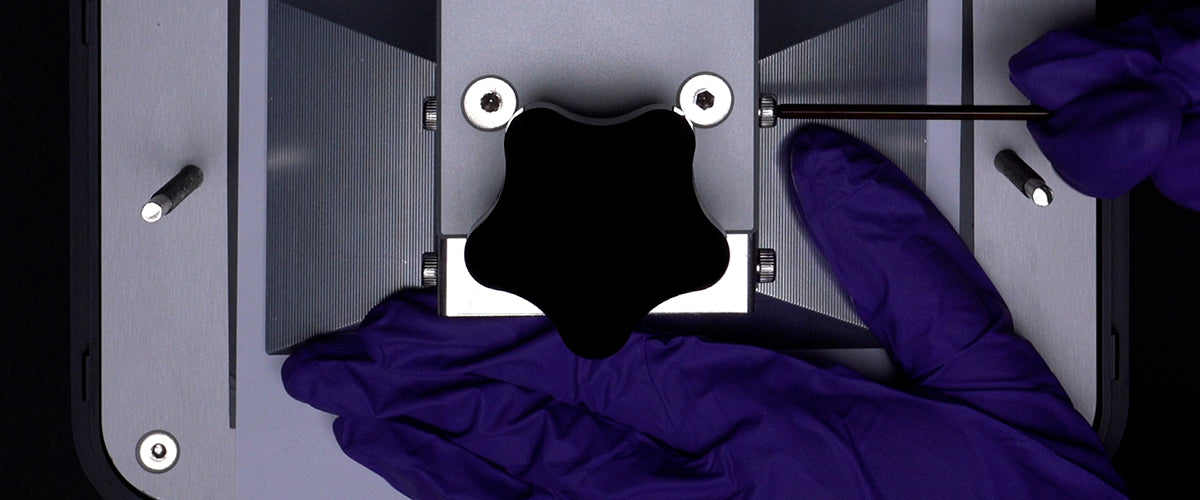

Step 8: Tighten the Screws in a Cross Pattern Order

Once you have successfully adjusted the building plate, tighten all four screws on the sides of the building plate in a clockwise direction while pressing down on the building plate with the other hand, in a cross pattern order, e.g., top-right, lower-left, top-left, and lower-right.

Step 9: Double-Check Z-axis Calibration

Tug on all four corners of the A4 paper to check for pressure intensity. If it is tight, please proceed onto the next step. If it isn’t, please perform the Z-axis calibration test again.

After several tries, if the paper is still loose, please perform the Z-axis Calibration test directly on the resin vat. The FEP thickness is approximately 0.14-0.15 mm.

Step 10: DONE

Click DONE on the touch panel and wait for the building plate to retract.

Once the plate has retracted, remove the A4 paper.

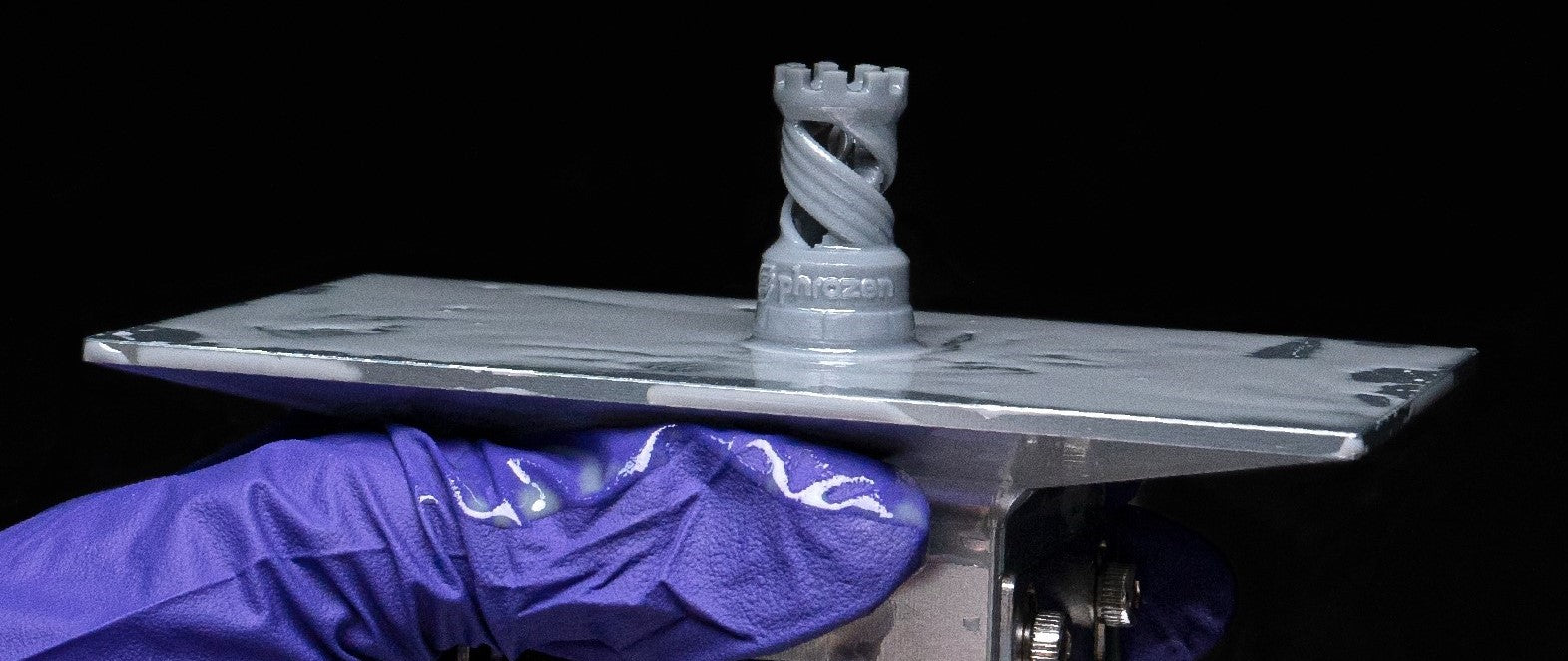

You are now ready to begin your 3D printing journey! Click here for a tutorial on printing out Phrozen's test file.

2 comments

Dave Adams

Needed to replace out z axis motor bearings, due to a resin spill. How do I reset the maximum distance the z axis will move in the upward direction? Thanks in advance, Dave.

———

Phrozen Technology replied:

Hi Dave,

To lift build plate, select TOOLS, then MANUAL after you’ve boot up your Sonic Mini 4K, where you can lift or lower the build plate manually.

If you need to replace your z-axis motor, please contact your local dealer or submit a request from the helpcentre or using the link down below. https://reurl.cc/lvd5kq

Regards, Phrozen Team.

>

Needed to replace out z axis motor bearings, due to a resin spill. How do I reset the maximum distance the z axis will move in the upward direction? Thanks in advance, Dave.

———

Phrozen Technology replied:

Hi Dave,

To lift build plate, select TOOLS, then MANUAL after you’ve boot up your Sonic Mini 4K, where you can lift or lower the build plate manually.

If you need to replace your z-axis motor, please contact your local dealer or submit a request from the helpcentre or using the link down below. https://reurl.cc/lvd5kq

Regards, Phrozen Team.

>

Amaury

Do I have te recalibrate the Z-axis every time I turn the printer on?

———

Phrozen Technology replied:

Hi Amaury,

No, you don’t need to recalibrate the Z-axis every time you turn the printer on. However, here are some conditions in which recalibration might be required: 1. When you just installed an LCD screen protector 2. When the building plate is not level and unstable 3. When you change to a thicker resin than the one you normally use. Hope this helps.

Cheers, Phrozen Team

>

Do I have te recalibrate the Z-axis every time I turn the printer on?

———

Phrozen Technology replied:

Hi Amaury,

No, you don’t need to recalibrate the Z-axis every time you turn the printer on. However, here are some conditions in which recalibration might be required: 1. When you just installed an LCD screen protector 2. When the building plate is not level and unstable 3. When you change to a thicker resin than the one you normally use. Hope this helps.

Cheers, Phrozen Team

>