As 3D printing continues to make its way into various industries, it has become clear that the scope of resin 3D printing is far from limited to your typical desktop models and tabletop miniatures. This has created a demand for functional resins with various engineering properties—and high-temperature resin is easily one that attracts a lot of attention.

With the versatility of 3D printing and its ability to create intricate designs and functional prototypes, a high heat resistant resin is the cherry on top to bring this exceptional technology even further. No need to worry about resin melting and changing shape due to continuous heat exposure.

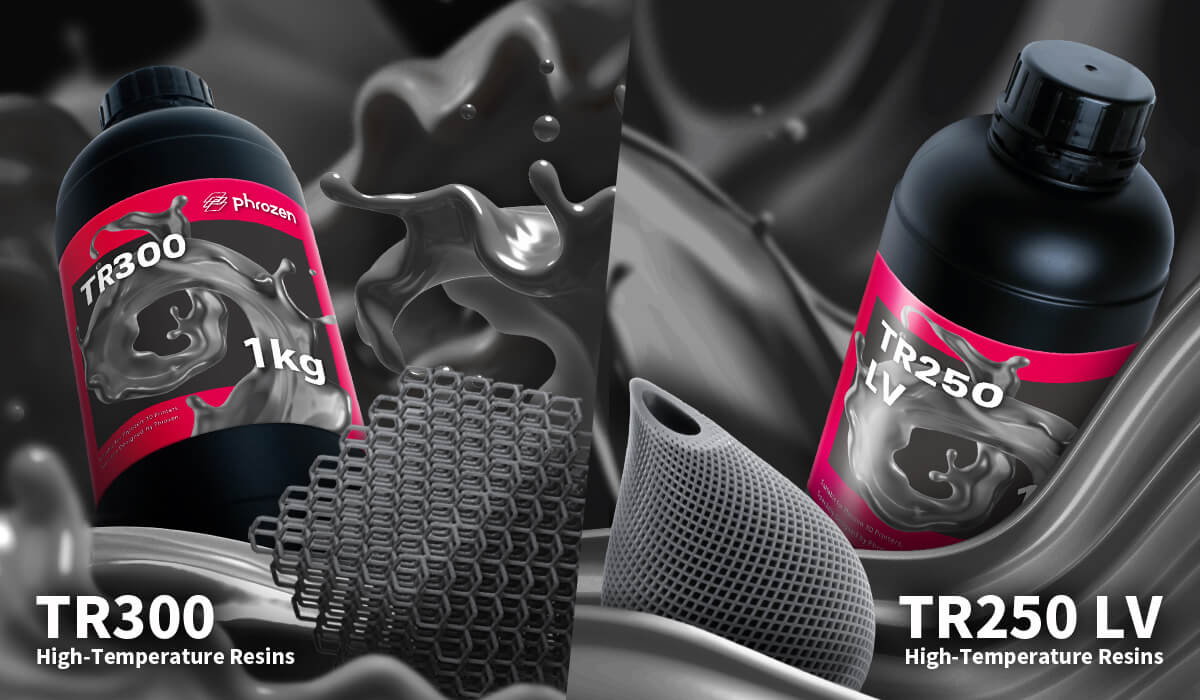

One of the best high temp resins on the market is arguably the Phrozen TR300. As a low-viscosity resin with high mechanical strength, toughness, and extremely high thermal resistance, the TR300 is your perfect choice to print highly detailed model prototypes that would be in contact with a lot of heat. At 190°C high deflection temperature, it's highly suitable for industrial mock-ups, functional 3D printed parts, and even jewelry molding.

But, does high temperature resistance means it can hold flames?

Can You Burn High Temp Resin?

You might think that it's such an intrusive thought, but some of us literally brought those thoughts to life.

MorgensternPrinting is a famous French TikToker who shares a lot of his 3D printing projects including digital modeling, miniature painting, and of course, 3D printing. Occasionally, he'll also do printer unboxing and some resin testing, just like what he did with the TR300.

Although the TR300 is not inflammable, the heat resistance property is enough to tickle his interest. This time, we had an opportunity to have a chat with him regarding his thought process on the TR300, his thoughts after trying the resin, and of course, most interestingly, why he decided to burn the resin.

Can you share your initial thoughts and feelings about the TR300 Heat Resistant Resin? Were you excited, skeptical, or had any specific expectations?

I was very curious but didn’t know what to expect in terms of the quality and reliability of printing. I was just so excited to test it, then I just had to think about some printing ideas.

@morgensternprinting Résine résistante à la température ca fonctionne? Y’a t’il réellement un différence? 🤔 Let’s go tester ca! 🖨️ Imprimante3d : @phrozen_3d Sonic mighty 12k 🧪 Résine Anakin : @Chitusystems Conjure Standard 8k 🌡️ Résine Obiwan : Phrozen TR300 💻 Slicer 3d : @CHITUBOX Pro 👨🎨 Sculpteur : Tapsin sur @CGTrader #starwars #anakin #anakinskywalker #obiwan #obiwankenobi #obiwanvsanakin #anakinvsobiwan #mustafar #jedi #coteobscur #theforce #phrozen #phrozen3d #phrozensonicmighty12k #phrozenmighty12k #sonicmighty12k #mighty12k #phrozentr300 #tr300resin #conjureresin #conjurestandard8k #chitubox #chituboxpro #darthvader #darkvador ♬ son original - Morgenstern

What led you to decide to burn and bake the TR300 Resin? What were you hoping to achieve with this experiment?

A lot of people don’t read the user manual or manufacturer recommendations or specifications when they get a resin. Therefore, a lot of people ask me to burn the resin and check if it will persist. Personally, I know that the product is not designed to be burned or baked, but I thought the premise was so interesting. After thinking about it for some time, I found an idea, and there goes the launch of Notre Dame’s second episode of fire. (if you know, you know)

I was really surprised about the precision of this resin, especially considering its special properties. I was positively surprised! In regards to using the fire, there’s no significant difference between the standard resin I used and TR300 Resin, but it was fun to test out and compare for my channel.

For the bake-in-the-oven stuff, the idea was to compare two different resins under the same condition of heating. I was really surprised to see the level of degradation of the standard resin and how amazing the resistance of the TR300 is to heat!!

I was hoping to see what would happen when exposing 3D printing resin to extremely high temperatures. So I once again compare the standard resin to TR300 Resin to see their heat resistance property. It’s surprising to see how the TR300 still looks good even after baking. It’s definitely good content and an educational video to show to my followers. As a cherry on top, the model chosen was a wink to the Star Wars episode on the high-temperature Mustafar planet during the fight between Anakin and Obi-Wan.

@morgensternprinting Est-ce que la résine résiste au feu 🔥!? Je vous propose de comparer entre de la résine Standard et de la résine TR300 résistante à haute température 🌡️🥵! 🖨️ Imprimante 3d : @phrozen_3d Sonic mighty 12k 🧪 Résine Standard : @Anycubic Official Standard grey 🌡️ Résine HT : Phrozen TR300 high temperature #impression3d #notredame #notredamedeparis #cathedrale #cathedralenotredame #cathedralenotredamedeparis #eglise #architecture #phrozen #phrozen3d #phrozensonicmighty12k #sonicmighty12k #mighty12k #12k #phrozentr300 #tr300resin #anycubicresin #anycubicstandard #feu #hightemperature #hautetemperature #burn #fire #burning #gimli #lordoftherings #lotr #chaleur #hot #flammes #flamme ♬ son original - Morgenstern

What were the results of your experiment with the TR300 resin? Were there any unexpected outcomes or challenges you encountered?

The TR300 is much, much more resistant to temperature. While the standard resin started to crack at 150°C with integrity breaks, the TR300 High Temp Resin was still not affected at all.

What are your opinions and thoughts about the TR300 now? Would you use it again, and if so, for what specific applications or projects?

So far, my experience with the TR300 is really positive. It’s super easy to use, has good results in terms of quality and dimensional stability (retraction, resolution, shrinkage…), and is very efficient in resisting high temperatures.

Personally, I will recommend this product to my community members who are searching for good high heat resistant resin for industrial and prototype parts. Especially when people have their 3D printing parts in contact with some kind of heating system like a mini heater for their 3D printer, RC cars, car parts, and more.

As a functional, engineering resin, it’s important to mention that the TR300, despite its outstanding high heat resistance, is still a highly detailed resin. Typically, when something is designed to excel in some aspects, it might not be as good in other parts. But in this case, the TR300 is easily winning every round!

Well, But Should You Really Burn the Resin?

If you are using the TR300, the answer is an easy no.

Despite being a high temperature resistant resin the TR300 is not fireproof and will actually burn and melt when exposed to fire for an extended period of time. So, please don't try this at home.

But, if you need a resin that is actually fireproof, check out the FR9400 Resin. Formulated specifically to be fireproof to swiftly diffuse flame within 10 seconds, that's the kind of resin you would want for your electrical parts that might catch fire.

So again, please don't try to burn the TR300 at home due to curiousity because Thomas have done it for us.