Earlier this year, we launched a Kickstarter campaign for our first-ever debut on an FDM 3D printer.

Since our establishment in 2016, Phrozen has always been known for its resin 3D printer. Yet, around 2 years ago, we decided that Phrozen also has the opportunity to become an FDM 3D printer manufacturer, and we took the leap.

And so the journey began!

Curious about why we decided to take the path? Keep reading to see more about Peyton from Slice Engineering's conversation with our CEO — Ray Wu — about the future and background of Arco.

So, Why an FDM Printer?

Peyton is definitely not the only one who was curious. After being a pioneer of so many innovations in the resin 3D printing market, entering a whole new FDM market seems like a bold move.

But it was not without a through and through considerations and thoughts.

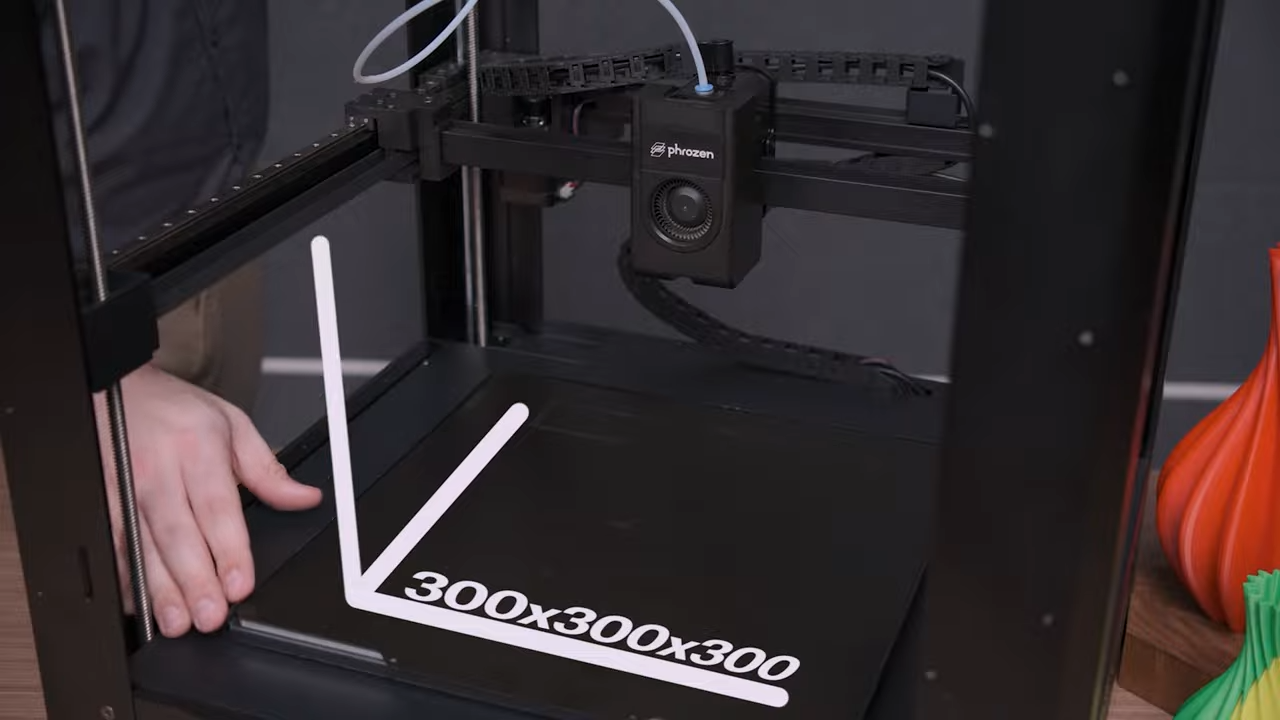

Ray said that the initial motivation for starting our venture into FDM 3D printing was our consumer feedback, asking for bigger printers.

While resin 3D printing offers extremely detailed prints and unmatched accuracy, the technology is easily limited by the size of the building plate and resin vat. A bigger build plate will require an even bigger resin vat, and a crazy big vat full of resin could easily become a major hazard for accidents and spills.

In addition, working with big resin prints is also tricky due to environment fluctuations and how setting supports for big, heavy, resin models requires a lot of experience.

So, turning into an FDM printer feels like a no-brainer when talking about big prints.

The Biggest Rock in Arco's Path

Ray shared that after some research, he soon realized that the mechanical design and motor control in most FDM 3D printers are pretty similar to those in resin printers. So, with over 10 successful resin 3D printers under his belt, this makes the changes itself way less complicated technology-wise.

A mere six months after the initial development of the Arco, Ray had a working prototype on his hands, and he was ecstatic about the result. A production plan was prepared, and material started to be sourced.

Then, another FDM 3D printer company released their printers, and the market changed overnight.

The new printer has since set a new standard in the filament 3D printer market. It's no longer just about big printing volume. People are expecting more: higher-end features, higher speed, multicolor printing, and every feature that someone could ever think of.

Arco was not ready for this sudden change in the market.

With a heavy heart, Ray decided to scrap the entire production plan for the initial Arco, and development started over from scratch.

It took two years to completely redesign the printer, enhance its features, and keep up with customer needs and market demand. Thus, the Arco was born.

Joining a Mature Market of Masters

While 8 years ago, we entered the resin 3D printing market as one of the pioneers, the filament printing market was already an incredibly mature one with tons of influencers, passionate creators, and lots of big brands crowding the market when we decided to join in.

This turned us from a full-fledged company to a newcomer to the industry. People already know our name, and we are expected to perform well, just like we did in the resin sphere, but we are not that experienced yet with the matter, and is still developing.

It puts a lot of pressure on our shoulders, but we are passionate about our work, and we want to make sure that we are delivering the best with Arco.

So, What Makes Arco Unique?

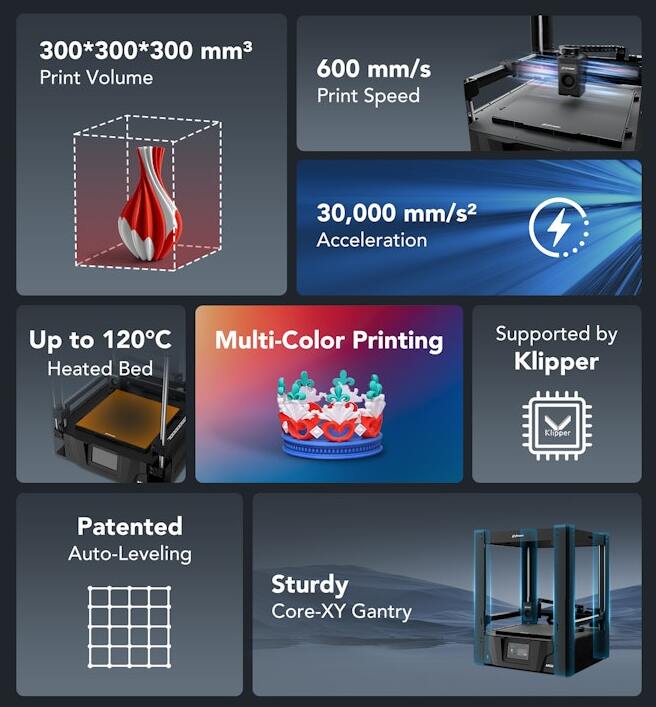

Multicolor 3D printers, sturdy gantries, a core XY printer, and open-source ones are already available in the market. But they are good on their own. Combined together, they're a challenge we're trying to overcome with the Phrozen Arco, making this printer a unique proposition of all the best offerings in the market combined into one powerful machine.

He hoped that those who received the Arco would appreciate its sturdy mechanical design. Built with all metal, the Arco is much stronger and solider than most printers with thin chassis currently available in the market.

Ray also discussed our decision to implement Klipper firmware on Arco. He saw that Klipper already does a really good job, and it might take a long time before we can do anything better than them. So, it only makes sense to use the best that's available for Arco.

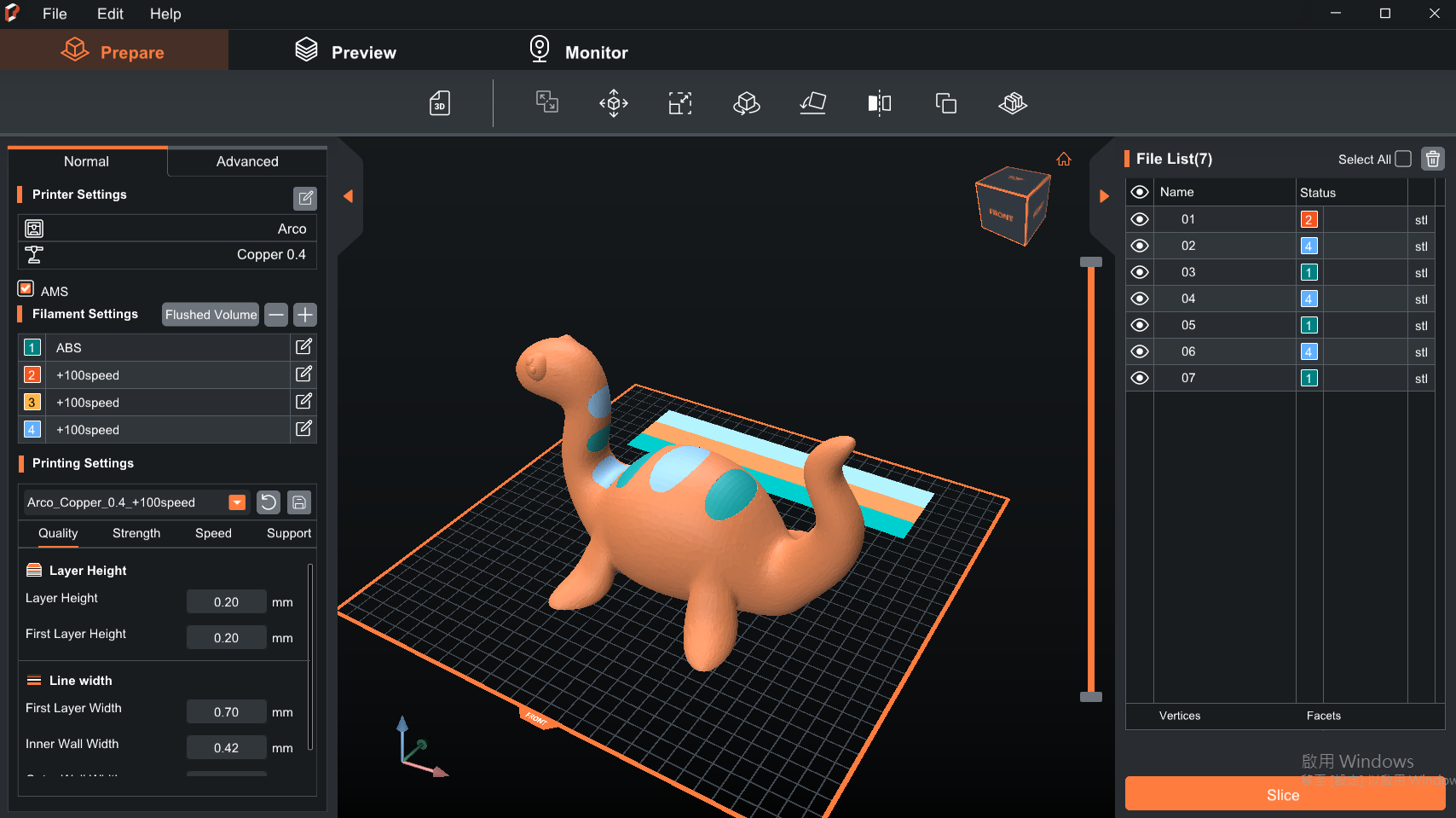

However, the situation is different for slicer software.

Currently, there are only one or two selections of slicers with multicolor printing on the market, and most are patent-protected. This forced us to go and develop our own slicer with a multicolor printhead for a special design to avoid patent violation. It’s also important for us to use our self-developed slicer for the Chroma Kit system as it gives us total control for further development on both the printer, the multi-material system, the slicer, and their integration.

The Future of Arco and Phrozen FDM 3D Printers

We have a long plan for our venture into FDM printing. This is just the beginning, and Arco is our first run.

In the future, we would like to offer a complete-solution FDM printer with a sturdy build, a heating chamber, and a printhead that can handle a wide variety of engineering materials, such as high-temperature nylon, polysulfane, peek materials, and more.

The ultimate goal for our FDM line will be to carry as wide a selection of materials as possible to fulfill our customers' needs for various printing applications, something that is not currently possible with resin printing.

As Ray mentioned, we are only at the beginning of our FDM journey, but we are excited to develop and grow with our users. Our Kickstarter campaign has ended with over 1400 backers putting their trust and faith in Arco, and we'll make sure to deliver the best for them.

Please join us on our journey with Arco by subscribing to our email list, and leave a comment below letting us know what you expect from Arco or our future FDM line!

Want to see the whole conversation between Ray and Peyton? Watch the video below!