Have you ever spent hours meticulously designing a 3D model, only to find that the print didn’t come out as you hoped? Maybe the details were too rough, or the surface was too textured. You’re not alone. Many people face this problem, especially when using traditional 3D printing methods like FDM (Fused Deposition Modeling), which often leaves layer lines and lacks the fine detail you need. It’s frustrating, right?

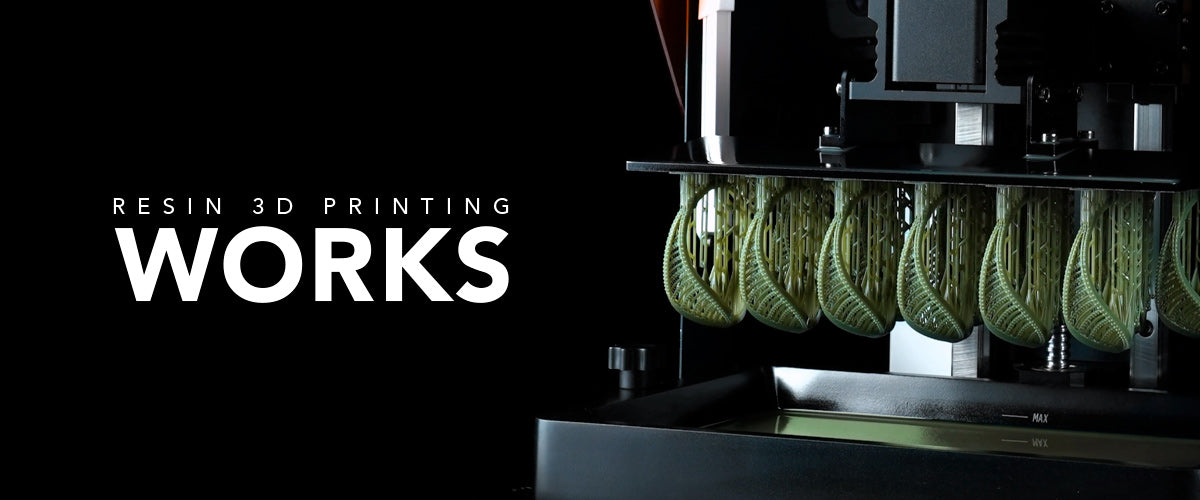

Here’s the solution: resin 3D printing.

With resin 3D printing, you can achieve incredibly smooth surfaces and capture the fine details that filament printing just can’t deliver. It’s the go-to method for high-resolution prints, whether you're making intricate jewelry designs, dental models, or tabletop miniatures. The precision is unmatched, but how does this magic actually work? Don’t worry; we’re about to break it all down for you!

In this guide, we'll take you step-by-step through the resin 3D printing process, explore the different types of resins, and answer all the key questions to help you decide if this printing method is right for you.

What is Resin 3D Printing?

Before diving into how resin 3D printing works, let’s first understand what it is. Resin 3D printing, also known as Stereolithography (SLA), uses a liquid resin that solidifies when exposed to UV light. Unlike filament 3D printing, which uses melted plastic to form layers, resin printing offers higher precision and a much smoother surface.

But here’s the catch: the process is slightly more complicated and requires a bit of post-processing. Still, the results are usually worth it, especially if you’re after fine details that standard FDM printers can’t achieve. Wondering how resin 3D printing compares to filament printing? Here's a helpful comparison.

How Does a Resin 3D Printer Work?

Now, let’s get into the nitty-gritty of how does resin 3D printing work. The process involves several steps that work together to transform a liquid resin into a solid object.

Layer-by-Layer Printing: The print begins when the resin printer uses a UV laser to trace and solidify each layer. A platform inside the printer moves up and down, dipping into the resin, and the UV light hardens the exact areas needed for that layer. This process continues, layer by layer, until the object is fully formed.

Post-Processing: Once the print is finished, the model is still covered in liquid resin. You’ll need to wash away the excess resin using isopropyl alcohol. Then, the print needs to be cured under UV light to ensure it’s fully solid. At this point, you’ll also need to remove any supports and smooth out the surface.

Sounds straightforward? It is, but there’s a lot more detail to it, and that's why resin 3D printing is a bit more specialized than filament-based printing. It requires additional equipment and materials, like curing stations and cleaning stations, to ensure the best results.

What is 3D Printing Resin Made Of?

If you’re wondering what 3D printing resin is made of, you’re not alone. Understanding the materials you’re working with is crucial to getting the most out of resin 3D printing.

The resin used in SLA printing is typically made from liquid photopolymer. These polymers are designed to harden when exposed to UV light. However, different types of resin have different properties.

Here are the most common types:

- Standard resin: This is the go-to resin for most users. It’s affordable, versatile, and produces high-quality prints with smooth surfaces.

- Transparent resin: As the name suggests, this resin is clear and is often used for creating transparent parts. It requires post-processing to achieve full clarity.

- Castable resin: This is ideal for applications like jewelry making or dental work. The resin burns out cleanly, leaving behind a mold for casting.

- Flexible resin: Want a little more give in your model? Flexible resin mimics the properties of rubber, making it great for parts that need to bend or flex.

These different resins offer versatility in how you approach your projects. For example, if you’re looking to create a mold or a highly detailed prototype, castable resin might be your best bet. Learn more about the different types of resin for 3D printing.

How Much Resin Do I Need for 3D Printing?

A common question for beginners is: how much resin do I need for 3D printing? The answer depends on several factors, such as the size of your model, the density (infill), and the overall design.

Here are a few tips to help you estimate:

- Model size: Larger models naturally require more resin. However, you can reduce the amount by hollowing out your design.

- Infill percentage: If your print is solid, it will use more resin. Many models don’t need to be completely solid, so you can save resin by adjusting the infill percentage.

- Supports: Don't forget that supports use extra resin, so try to minimize their use where possible.

As a rule of thumb, if you’re printing a small, detailed object like a mini figurine, you might use anywhere between 20 to 50 milliliters of resin. Larger models, especially if they’re solid, can use over 100 milliliters. Knowing how much resin your printer uses will help you avoid running out mid-print. For example, when working on a project, always check your design's estimated resin usage, which is often calculated by slicing software.

How Long Does Resin 3D Printing Take?

Another essential consideration is how long resin 3D printing takes. Resin printing is generally slower than FDM printing because the process is more delicate, focusing on high precision.

The time required for printing depends on:

- Layer height: Thinner layers will take longer to print but will produce more detailed results. Common layer heights for resin printing range from 25 microns (extremely fine) to 100 microns.

- Model size: Larger models take longer to print, especially if you’re printing at a finer resolution.

- Post-processing: After printing, you’ll need additional time for cleaning, curing, and removing supports, which adds to the overall time.

In general, a small, detailed print might take around 2 to 4 hours, while a larger, more complex print could take 12 hours or more.

To speed up the process, our blog on 3D printing faster is a must-read. It covers all the industry techniques to 3D print faster without losing out on the details.

How Long Does 3D Printer Resin Last?

Now, if you're considering investing in resin 3D printing, you might wonder: how long does 3D printer resin last? Unused resin, if properly stored, can last up to a year or even two. However, resin degrades over time, especially when exposed to UV light and heat, which causes it to harden prematurely.

Here are some storage tips to maximize resin shelf life:

- Store in a cool, dark place: Sunlight and high temperatures are your resin's enemies.

- Seal the container tightly: Make sure the bottle or container is sealed to prevent exposure to air, which can also degrade the resin.

And what about resin already in your printer’s vat? If you don’t use it within a few days, you’ll want to pour it back into the bottle to avoid it going bad.

Is Resin 3D Printing Worth It?

So, with all the equipment, materials, and extra steps, you’re probably wondering: is resin 3D printing worth it? The answer really depends on your needs.

If you’re a hobbyist or a business looking to create highly detailed prototypes, miniatures, or even functional parts for specialized industries like dentistry or jewelry, then resin printing is absolutely worth it. The detail and smoothness are second to none compared to FDM.

However, there are some downsides. Resin printing requires more post-processing, the materials can be more expensive, and the prints are often more brittle than those made from filament. If you’re just starting in the world of 3D printing, an FDM printer might be a better first step. Check out our comprehensive resin Vs. filament 3D printing guide to thoroughly understand which one better suits your needs.

Resin 3D Printing Explained: Pros and Cons

Let’s break it down even further. Here’s a quick comparison of the pros and cons of resin 3D printing to help you decide if it’s the right choice for your projects.

Pros:

- Unmatched precision: If detail is your top priority, nothing beats resin.

- Smooth surfaces: Resin prints generally don’t need as much finishing as filament prints.

- Great for small prints: If you’re working on jewelry, dental models, or miniatures, resin printing is the way to go.

Cons:

- Expensive materials: Resins cost more than filaments, and the cost can add up.

- Post-processing: Requires washing, curing, and sometimes sanding to get the final product.

- Health and safety: Many resins are toxic, so you need to handle them with care. Want to know more about safety precautions? Learn more through our in-depth resource on 3D printing safety.

Conclusion

In conclusion, how does resin 3D printing work? It offers a precise and high-quality alternative to filament-based printing, making it ideal for detailed and professional applications. However, the cost, post-processing, and material handling require a bit more commitment.

For projects that demand fine detail, such as jewelry, medical models, or miniatures, resin printing is definitely worth the investment. If you're ready to take your 3D printing to the next level, resin 3D printing could be just what you need.

Curious about how the overall 3D printing process works? Here’s a guide to 3D printing basics.

1 comment

Ron West

With all the “everything to know about 3d resin printing” articles online, I’m still looking for the explanation of the very beginning of the process! Where does your artwork or model come from? Do you have to design it with a particular app? Does the 3d printer scan a physical object that you are trying to reproduce? How does the process begin?

———

Phrozen Technology replied:

Hello Ron, Thank you for commenting.

As you said you need something to print before you can start printing. 3D models are basically digital form of sculptures, most of people create their own model from scratch using 3D modelling software such as Blender, Rhino, Zbrush etc. Some people will use 3D scanner to create a roughly digital copy of an object existing in real world, then refine, modify or make their own creation based on that scanned concrete object.

Some people only want to enjoy the process of paining a model, building figurines or dioramas. They will download the 3D model file that has been already made by other people and use their 3D printer to make other people’s digital creations into a real life object. You can find those files on website such as Thingiverse, MyMiniFactory or Cults3D. PIXUP is also a 3D model downloading website which accepts some of the top tier 3D modellers in the world through their artist verification program, to ensure the quality of the models they provide. There are also with some uploads on PIXUP tagged as “Phrozen Verified” which means it comes with pre supported version of the model, checked and optimized by expertise, guaranteeing over 95% success rate with properly dialled setup.

Check out models on PIXUP now: https://pixup3d.com/

Best, Phrozen Team

>

With all the “everything to know about 3d resin printing” articles online, I’m still looking for the explanation of the very beginning of the process! Where does your artwork or model come from? Do you have to design it with a particular app? Does the 3d printer scan a physical object that you are trying to reproduce? How does the process begin?

———

Phrozen Technology replied:

Hello Ron, Thank you for commenting.

As you said you need something to print before you can start printing. 3D models are basically digital form of sculptures, most of people create their own model from scratch using 3D modelling software such as Blender, Rhino, Zbrush etc. Some people will use 3D scanner to create a roughly digital copy of an object existing in real world, then refine, modify or make their own creation based on that scanned concrete object.

Some people only want to enjoy the process of paining a model, building figurines or dioramas. They will download the 3D model file that has been already made by other people and use their 3D printer to make other people’s digital creations into a real life object. You can find those files on website such as Thingiverse, MyMiniFactory or Cults3D. PIXUP is also a 3D model downloading website which accepts some of the top tier 3D modellers in the world through their artist verification program, to ensure the quality of the models they provide. There are also with some uploads on PIXUP tagged as “Phrozen Verified” which means it comes with pre supported version of the model, checked and optimized by expertise, guaranteeing over 95% success rate with properly dialled setup.

Check out models on PIXUP now: https://pixup3d.com/

Best, Phrozen Team

>