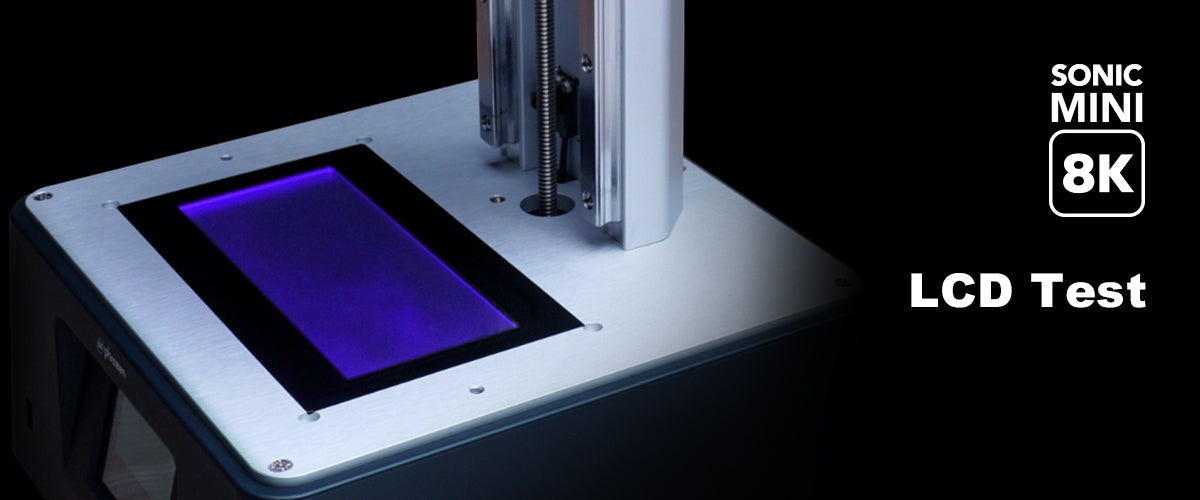

Before printing, you may need to check the status of your Sonic Mini 8K's LCD screen. This is to ensure that both the UV lights and the 7.1” Mono-LCD screen are functioning properly. We will guide you through the steps of performing an LCD test and how you can read the test:

*Caution! DO NOT look directly into the light. Improper exposure to UV light may cause painful eye and/or skin injuries.

Step 1: LCD TEST

On the touch panel, click TOOLS, then click on LCD TEST:

1. A white rectangle will appear on the LCD screen. Run this test to make sure that the image shown on the LCD screen matches the one shown on the touch panel.

Step 2: VAT CLEANING

Click TOOLS, then click VAT CLEANING.

Set the Vat Cleaning exposure time to 15 seconds.

Then click on Next.

On the LCD screen, a bright blue square will appear. Run this test to make sure the UV lights are distributed evenly.

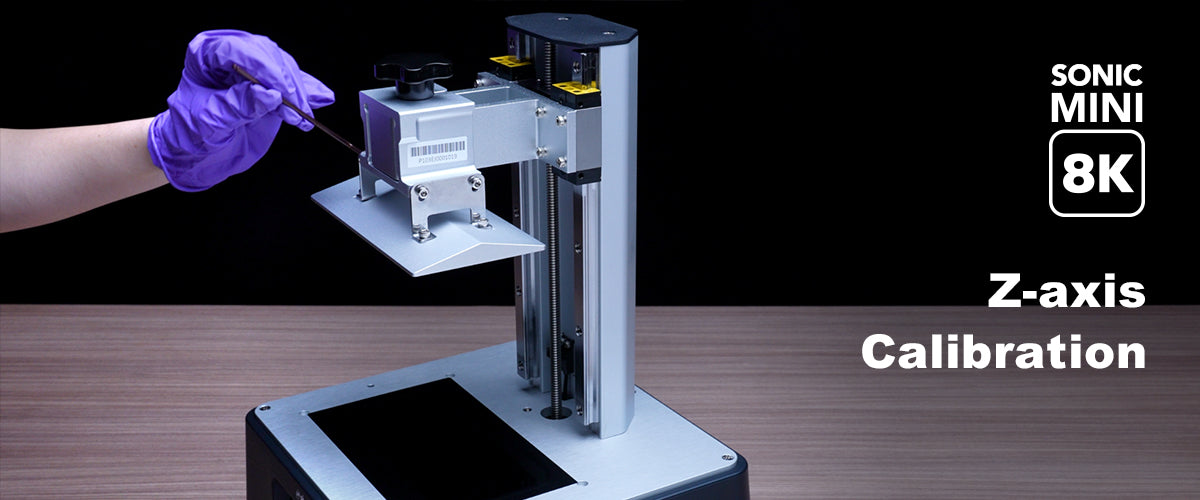

Step 3: Z-axis Calibration

After making sure everything is functioning correctly on your LCD 3D printer, you’re all set to proceed to the next step: Z-axis Calibration.