Just like how our CEO and founder found his passion for 3D printing during his study, we have since aimed to support the development of new technologies in education and academia through collaboration with enthusiastic minds who are passionate about their field. By offering a hand and support to those who wish to expand their knowledge and experience with the help of 3D printing, we are excited to see how 3D printing can further revolutionize the world in the future.

Recently, we’ve collaborated with the National Taiwan University of Science and Technology (NTUST) Formula Racing Team to explore the application of innovative technology like resin 3D printing in the automotive industry.

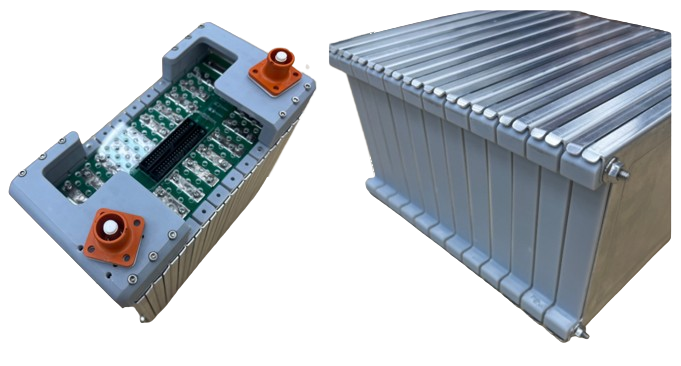

Taking advantage of our new flame retardant resin — FR940, the NTUST racing team has successfully manufactured a battery holder that’s not only safe for racing purposes but also light enough not to sacrifice the speed of the car. Want to learn more about this collaboration? Well, keep reading…

Opening A New Era of Electric Cars With Resin 3D Printing!

First established in 2021, the NTUST Racing Team initially participated in the Formula Society of Automotive Engineers (FSAE) with the focus of building an excellent gasoline-powered race car. However, after being faced with various difficulties in obtaining the required engine parts, the team decided to swerve their focus to join the electric vehicles (EV) categories, later birthing their first ever electric formula racing car, a crucial representation of NTUST's foray into the electric vehicle domain — EV927.

Our collaboration started when the NTUST Racing Team was looking for innovative technology to safely hold their power source. Challenged by the difficulties in acquiring engine components, the team pivoted its strategy to resin 3D printing technology.

At the same time, we have just recently developed our first flame retardant resin, a flame retardant material that’s capable of diffusing flame in less than 10 seconds upon burning. Models printed by the FR940 will have the safety standard required by a battery holder, keeping it safe in the occurrence of fire. Implementing a flame retardant material in their formula race car marked a new chapter in the NTUST Racing Team’s electric vehicle development.

The First UL 94 V-0 Blue Card Certification in Asia

While the FR940 flame retardant capability makes it an obvious choice for the NTUST racing team, it wasn’t a shot in the dark.

The FR940 Flame Retardant Resin is an industrial resin with excellent flame-retardant properties developed for high-quality industrial components. As the first resin in Asia to obtain a UL 94 V-0 Blue Card certification by Underwriter Laboratories, it has been tested by reputable and trusted standards in the industry. The FR940 is suitable for electronic and electrical uses, automotive parts, medical equipment, and other products that require high flame retardancy while maintaining safety and practicality.

In addition to its capability to diffuse flame in less than 10 seconds, it also has low-density characteristics. This gives another advantage to the team as heavy battery holders made of industrial material tend to be heavy and weigh down the car’s speed.

Why the FR940 is great for industrial applications:

- Lightweight Formula: Models 3D printed with the FR940 have low density, reducing unnecessary weight strain on machinery and engines. In this case, it successfully reduces the weight of the battery holder, enhancing the performance of the formula racing car.

- Outstanding Flame Retardancy: Safety is a paramount consideration in many industrial applications, especially in extreme conditions. FR940 not only exhibits exceptional flame retardancy but also ensures the reliability and safety of the battery holder in extreme conditions.

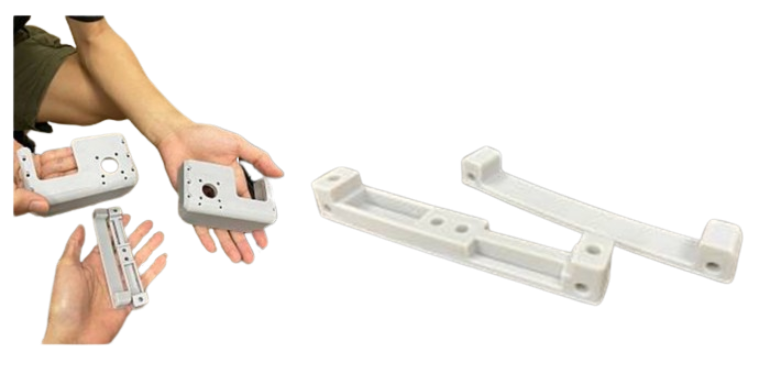

- Precise 3D Printing: Manufacturing through 3D printing brings another advantage as each model can be modified slightly according to the requirement without adding significant extra cost. After all, each part can be created individually while ensuring its accuracy and consistency.

Excellence in the Efforts

Our collaboration with the NTUST Racing Team goes beyond technical exchanges, embodying a shared pursuit of excellence and innovation. This collaboration witnessed the close integration of technology with the automotive industry as we became a part of the NTUST Racing Team’s journey in the recent Formula SAE Australasia race.

First Car Presentation on September 2023

Their achievement in the FSAE Australia not only reflects their team's efforts but also serves as a successful testament to the limitless possibilities of technological collaboration. Having successfully brought home the Harry Watson Award, they are acknowledged to have made a distinct contribution by rebuilding a complete battery pack in just 2 days. The contribution of FR940 has supported their performance in passing all the static tests and standing out in a fiercely competitive environment.

This collaboration is just a small step for us toward the future. We will continue to deepen our expertise in light-curing 3D printing technology and continue to innovate and expand our selections in resin materials, offering better options for various use cases as well as participating in the development of the automotive industry. We look forward to collaborating with more outstanding teams in the future, jointly exploring new frontiers in the integration of technology and the automotive industry.

Want to read more about how resin 3D printing takes part in a solar race car? Check out how the winner of the 2023 Bridgestone World Solar Challenge used our products.